Injection Molding Machine Chapter 4

V3.0

4-24

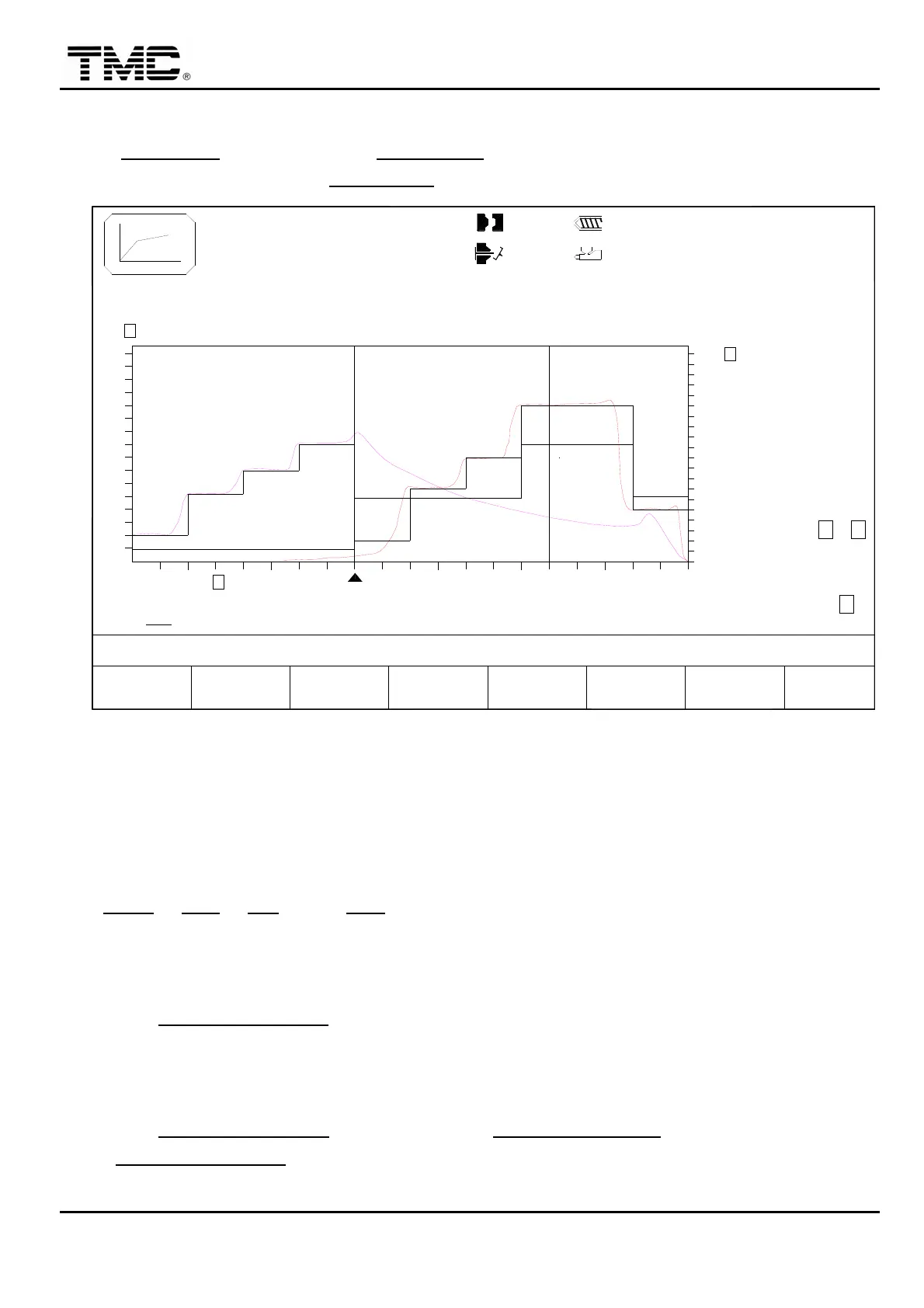

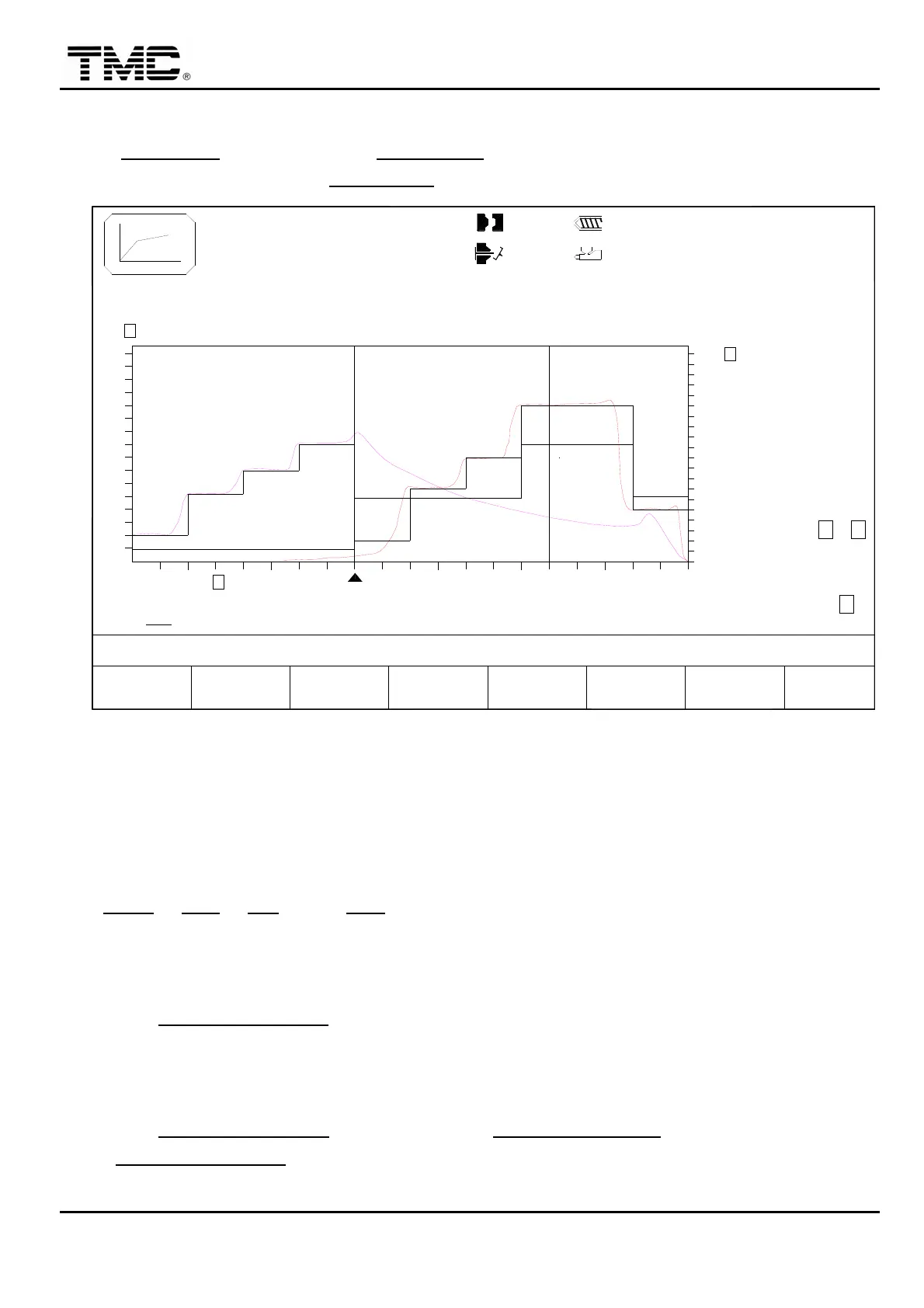

2.11 Injection closed loop control

On INJECTION screen press F4 INJ. GRAPH or use the direction key in the main menu

screen to move the cursor to INJ. GRAPH,press ENTER to display this screen.

V1: 0/ 0 0/ 0V2:

0/ 0P1: 0/ 0 P2:100.0mm

100.0mm110.0mm

1.0mm

ACTION STATUS

M:

03D05M07Y

10h25m10s

20°C3W

: 100%

P ACTUAL

V ACTUAL

F2F1 F3 F4 F5 F6 F7 F8

MODEMENU

01

: 100Bar

= sec.

P ACT

: 95bar : 76%

CPM

CPP

CPI

CPD

FUNCT.

TRANS. PT

: 10.0mm

INJ. END PT.

START PT.

INJ. T.

: 80.0mm

: 1.2sec

ON ON

HOLD P

INJ.

= 2.5 sec.

P SET

: 100bar : 75%

V SET

V ACT

= 50.0mm

= 50.0mm

CURSOR CLEAR

DATA

WINDOW

SCALE<-

WINDOW

SCALE->

A

B

X=TIME:OFF

F

P/V

RAMP

0

100%

E

135

90

45

180

0

100%

50

25

75

100

%

D

bar

C

50

0

10

10

50

0

10

10

: 6.5mm

Screen 4-14

1.It is an optional device,by means of a pressure transducer on the injection cylinder,the

actual pressure of the cylinder can be measured,through the high speed closed loop control

inside the control computer,makes the molding process more accurate.

2. CPM, CPP, CPI, and CPD are closed loop control parameters,which have been

adjusted precisely before factory delivery,users shall not change them to prevent affecting

the machine performance.

3.When F3 CURSOR MODE ON,direction key”↑” is for quickly left shift,“←” is for slightly

left shift,“↓” is for quickly right shift,“→” is for slightly right shift. They can be used to move

vertical line to check the position,pressure,speed and time.

4.When F3 CURSOR MODE

OFF,press F6▲ P/V TRANS. POINT move to left,press F7

▲ P/V TRANS. POINT

move to right. It could be used to enlarge and reduce the injection

speed and holding pressure scale.

Loading...

Loading...