Injection Molding Machine Chapter 4

V3.0

4-26

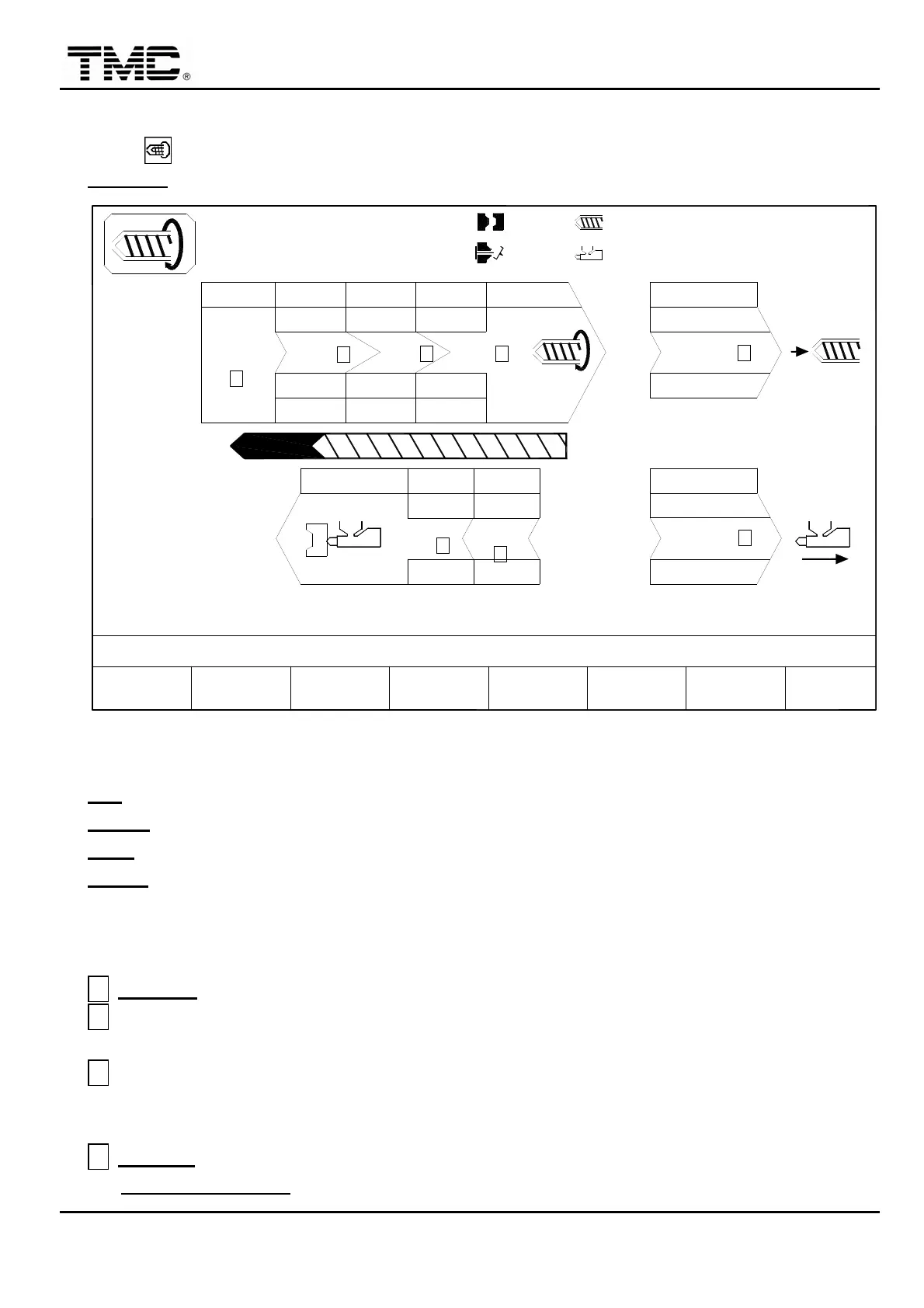

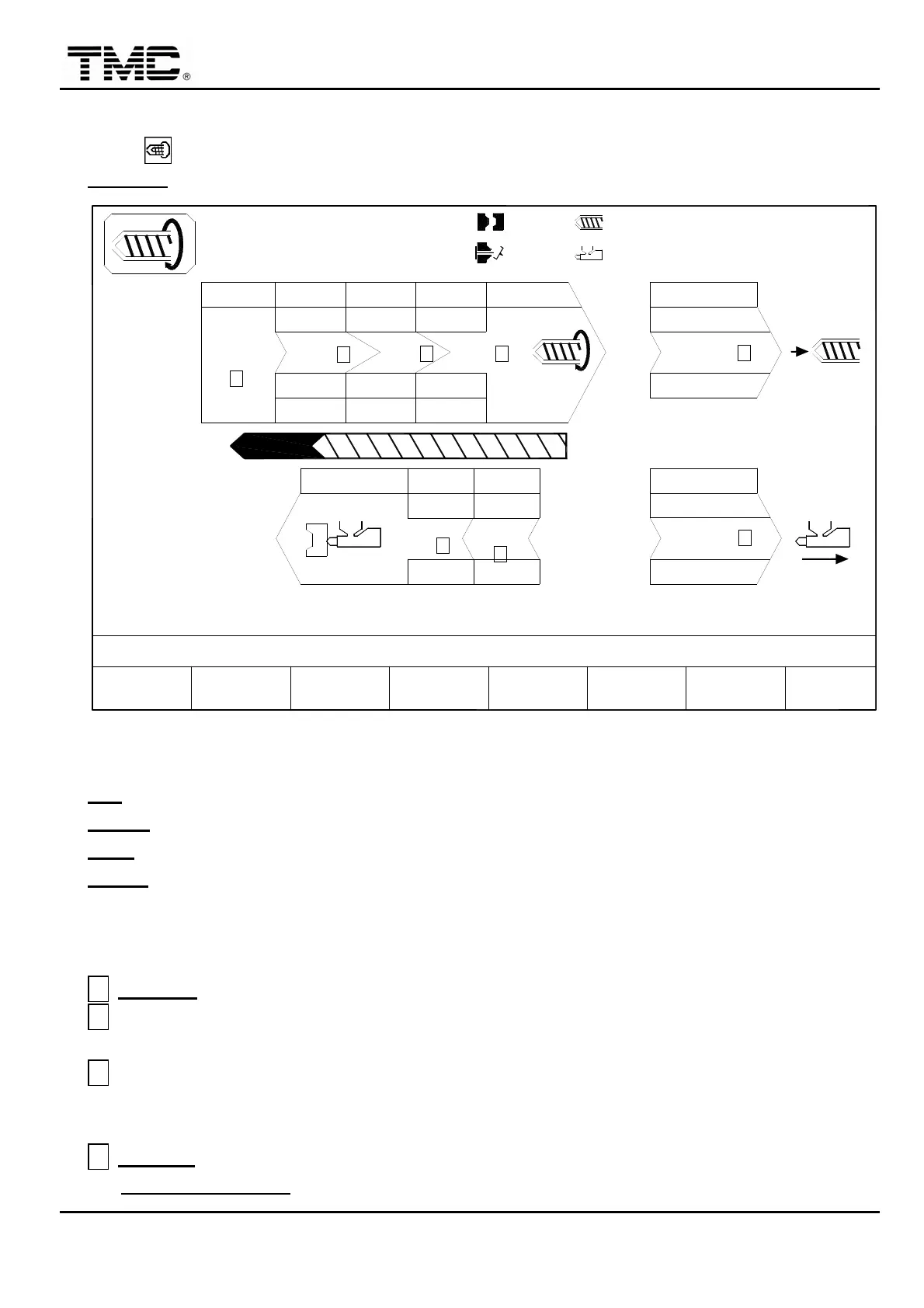

2.12 Charge /Carriage setting

Press hot key or use the direction key in the main menu screen to move the cursor to

CHARGE

,

press ENTER to display this screen.

10h25m10s

20°C

ON

< 5.0>

PARAMETER

CHARGE

03D05M07Y

F2F1

MENU

01

SUCK BACK

COOLING T.

B.P ACT. 0

CARRIAGE

BPbar

PTmm

Pbar

10.0

A

V%

INJ. END

3W

CHARGE MONITOR T.

CHARGE DELAY T.

MOLD

SUPPORT

F3 F4 B.P.AUTO

PURGE PROFILE

0.0

100

F5 F6CHANGE

LOG

70

Pbar

PROD.

MANAG.

F7 F8

FUNCTION

< 10.0> 000.0

<000.0> 000.0

70

100.0mm

100.0mm

100.0

F.W. END

20

10.0

G

2

70

1010

20.0

70

B

10

50.0

60

C

80

250.0

F

1

V%

PTmm

WGT. g

120.0

D

10050

12

100

3

1.0mm

CH. END

RPM 0

110.0mm

H

80

250.0

B.W. END

E

+10.0

50

0/ 0

0/ 0 0/ 0

SUCK B.

40

P1:

SUCK

BACK

P2:

0/ 0V1: V2:

ACTION STATUS

M:

Screen 4-15

V %

:

Speed setting in percentage

,

0%~100%.

PT mm

:

Position setting

,

uses the

※

on the panel to input decimal point..

P bar

:

Charge pressure setting value. (Screw rotation pressure)

BP bar

:

Charge backpressure setting valve. (Digital back pressure model)

2.12.1 Charge setting

A

INJ. END

:

It is the read value of injection end position

,

which could not be changed.

B

Charge speed 1 to speed 2 switch position

:

usually a short distance is set so that screw

can be started slowly from standstill.

C

Charge speed 2 to speed 3 switch position

:

this is the position for changing fast speed to

low speed

,

and it is usually set at 3.0~5.0 before charging stop position for enhancing the

stability of stop position.

D

CH. END

:

This is charging end position.

CHARGE DELAYT. can be adjusted to delay charging startup to reduce material

Loading...

Loading...