-11-

TROUBLE CAUSE REMEDY

No ash

Spark plug

1.Poles wet Dry it

2.Covered with carbon Clean the carbon

3.The insulation damaged Replace

4.Spark gap incorrect Adjust 0.6

~

0.7mm

5.The poles burned Replace

Magneto

1.The wrap of wire damaged. Remedy or replace

2.Insulation of coil bad Replace

3.The wire of coil broken. Replace

4.The electronic ring unit defective Replace

Normal

Compression ratio and

fueling well

1.Too much fuel in cylinder Drain

2.Water or dirt in fuel Replace

Fueling well but

compression ratio bad.

1.Cylinder and piston ring wore or tore Replace them

2.The plug loose Tighten it

Carburetor not fueling

1.No fuel in tank Fuel

2.Fileter gauze clogged Clean

3.The air hole of the tank clogged Clean

(2)Engine lacks power

TROUBLE CAUSE REMEDY

The compression ratio is ne

1. The lter plate clogged Clean

2.Air passes through the

connection of carburetor

Tighten

3.Engine overheat Stop the engine and cool it

4.Water in fuel Rell with fresh fuel

5.The carbon clogs mufer Clean

Engine overheats

1.Mixed gas (fuel) thin Adjust the carburetor.

2.Cylinder covered with carbon Clean

3.Oil bad

Use 2-T engine oil and adjust the

mix ration.

4.No connection with hose Correctly assemble the machine

Engine noisy or knocking

1.Fuel bad Replace

2.Carbon in cylinder Clean

3.The running parts wore and

tore.

Check and replace

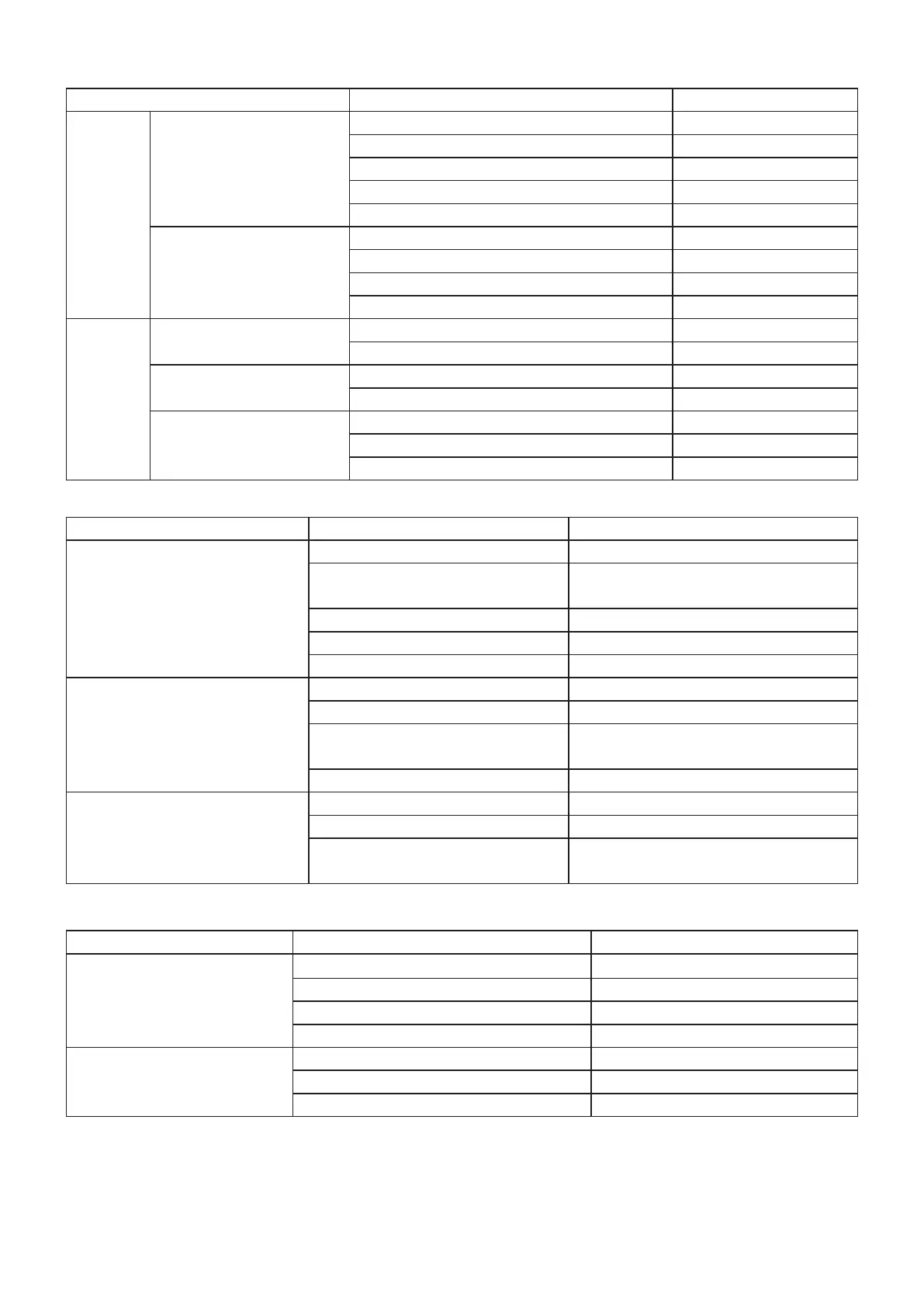

(3)Engine stops while running

TROUBLE CAUSE REMEDY

Engine stops suddenly

1.The lead wire of plug loose Replace rmly

2.Piston bitten Change or remedy

3.Plug covered with carbon Clean plug

4.Fuel used up Fill the fuel tank

The engine stops slowly

1.Carburetter clogged Clean

2.The air hole in the tank clogged Clean

3.Water in fuel Rell with fresh fuel

Loading...

Loading...