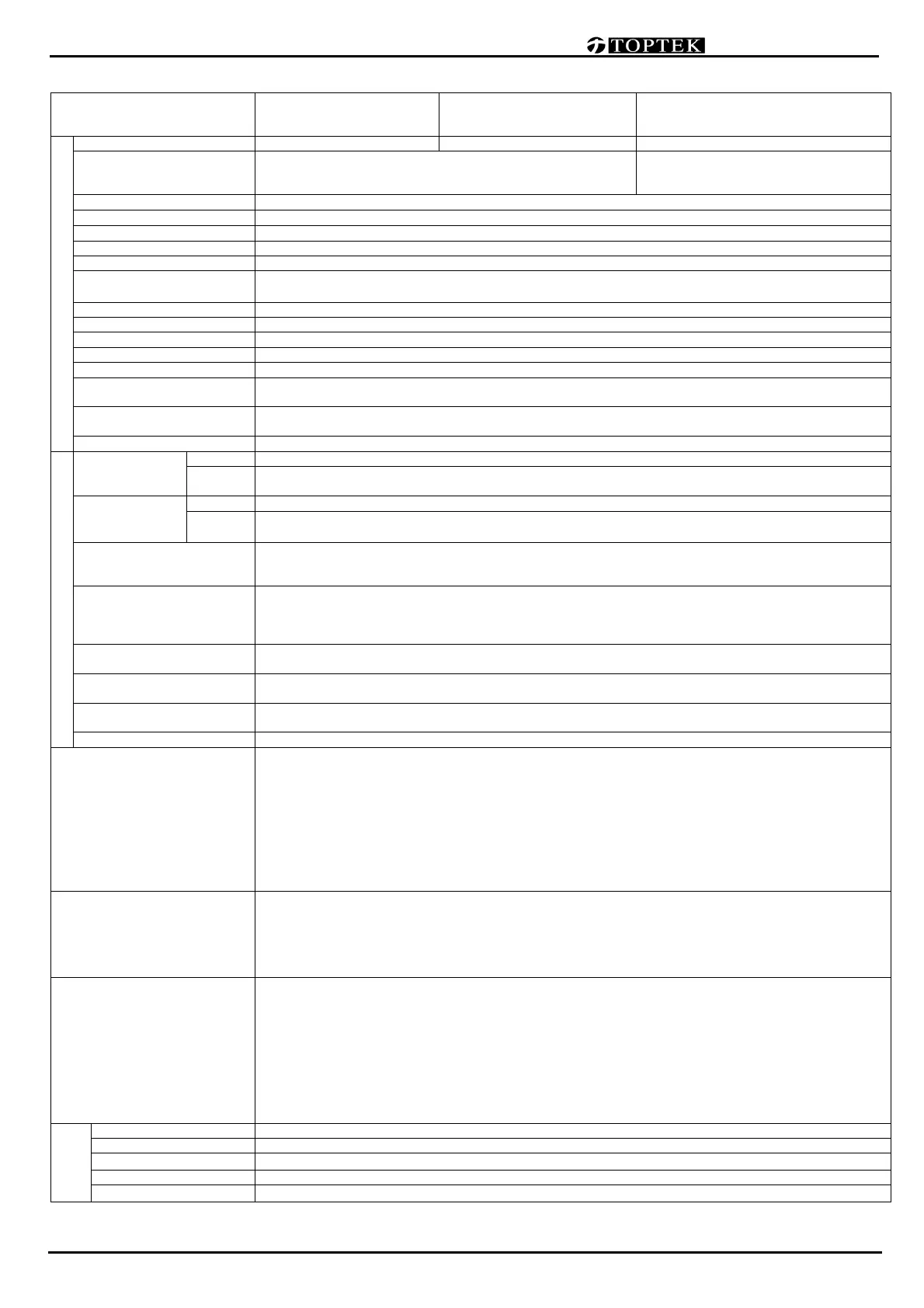

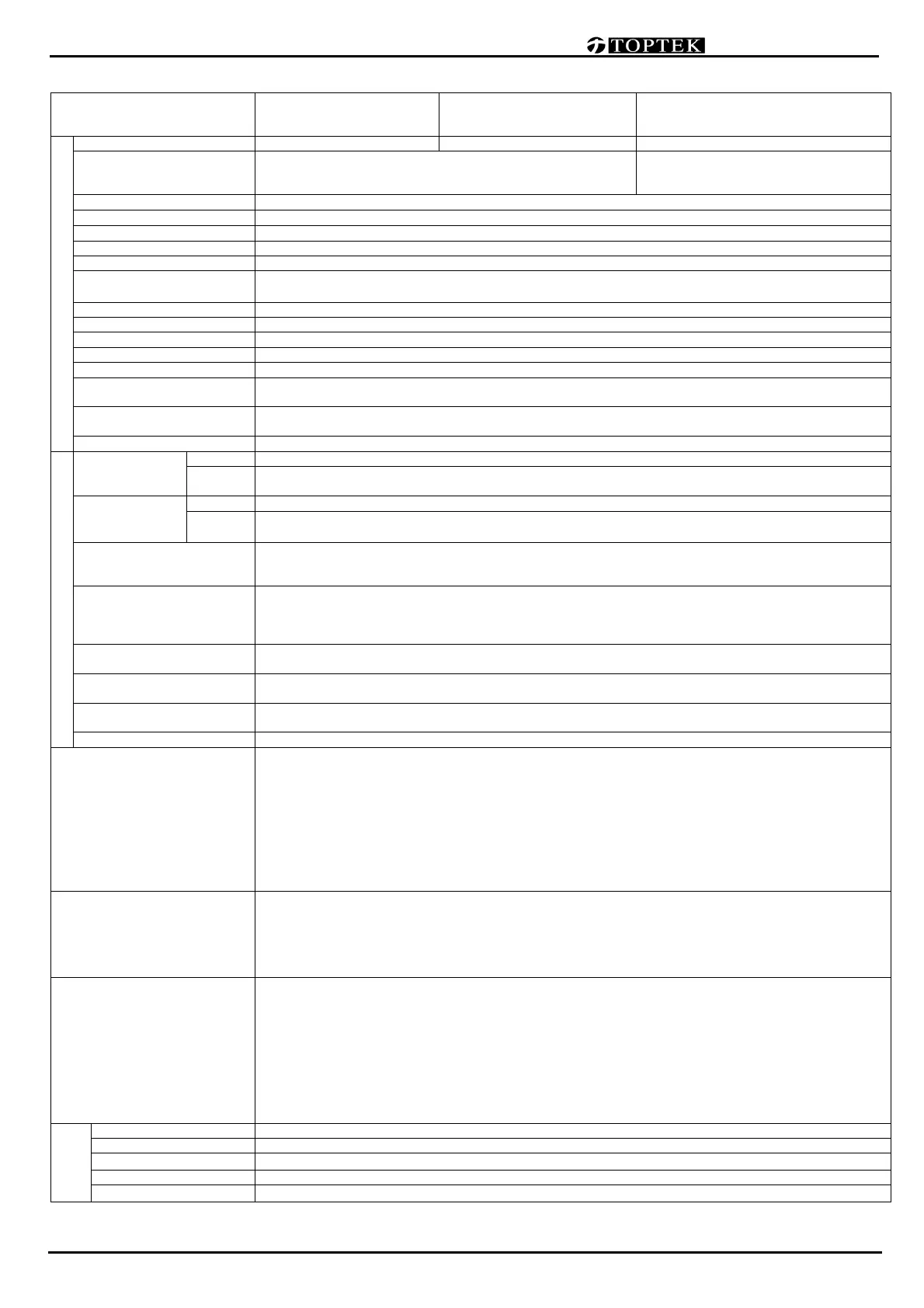

TOPVERT G1/H1/P1 Series

E-3

STANDARD SPECIFICATIONS

Series

TOPVERT G1 series

High performance general

purpose multi-function drive

TOPVERT H1 series

High performance high speed drive

TOPVERT P1 series

High performance variable torque drive

for Fan & Pump

Control Characteristics

Output frequency range 0.1 - 600Hz, Programmable 0.1 - 6000Hz, Programmable 0.1 - 600Hz, Programmable

Overload endurance

150% of rated current for 1 minute/10 minutes, Ta <=40, 200% of

rated current for 2 seconds

125% of rated current for 1 minute/10

minutes,

Ta <=40,165% of rated current for 2 seconds

Maximum output voltage Proportional to Input Voltage, 3-Phase output

Power factor/Efficiency Power factor no lower than 0.95. Efficiency no lower than 95% at full load

Control system SPWM (Sinusoidal Pulse Width Modulation) vector control, 4 control modes :V/F, V/F + PG, SVC & VC + PG

Speed control range V/F mode 20:1; V/F+PG mode 120:1; SVC mode 120:1; VC+PG mode 600:1

Output frequency resolution Analog input: 10Bit(1/1024), Digital input: 0.01Hz, Fly-Shuttle dial input: 0.01Hz

Output frequency accuracy

Analog input: Within ±0.2% of max. output frequency (25℃ ±10℃ ).

Digital input: Within 0.01% of set output frequency

PWM carrier Frequency 0.7 -18kHz, Adjustable (Some models are limited), H1: 1.4kHz ~ 36kHz, Adjustable

Torque characteristics auto-torque boost, auto-slip compensation; starting torque can be 150% at 1.0Hz

Skip frequency Setting range 0.00 -600Hz (H1series: 0.00 ~ 6000 Hz), Max. 6 points, skip width are adjustable

Accel/Decel time 0.1-60000 seconds ( 2 Independent settings for Accel/Decel Time)

Stall prevention 0 to 250% of Rated Current, independent adjustable both in acceleration and constant speed operation.

DC Braking

DC Braking both when start up and stop , Braking Current Level: 0 to 125% of rated output current. Braking time: 0

to 60 seconds. Braking Start-Point when stop: 0.1-600Hz (H1series: 0.00 ~ 6000 Hz)

Dynamic braking

Braking torque Approx. 20%(10%E.D.). Dynamic Brake chopper built-in in Frame code: xx-A and xx-B.

Others can be built-in as an option. All models can connect to external Dynamic Brake Unit (TDBU-xxxx series).

V/F Pattern 2 of adjustable Random V/F curve. Constant Torque curve & Reduced Torque curve are available.

O

PERATING

Characteristics

Frequency Setting

Keypad

By an Encoder style Fly-Shuttle dial. (setting resolution 0.01Hz/0.1Hz/1Hz/10Hz adjustable)

External

Signal

0 ~ +10VDC((Input impedance 20kΩ), -10 ~ +10VDC((Input impedance 10kΩ),4 ~20mA DC ((Input impedance

250Ω),Multi-Function Inputs 1 ~ 6 (15 Steps Jog, up/down), PLC run, RS-485 port MODBUS protocol

Operation Setting

Keypad

Set by RUN, STOP and JOG. Switch-able between Keypad and External signal

External

Signal

2 wire control(FWD/STOP、REV/STOP、RUN/STOP、FWD/REV), 3 wire control, FWD, REV, MI1 to MI6 can be

combined to offer various modes of operation, RS-485 serial interface MODBUS protocol

Multi-Function Digital Input

(DI)

(6 terminals)

Multi-step selection 0 to 15, first to second accel/decel switches, accel/decel inhibit, Input the counter, Pause Stop,

EF Input, Emergency Stop, auxiliary motor control is invalid, ACI/AVI/AUI speed command selection, Reset, PLC

Run, Jog, Up/Down command, Sink/Source selection, Parameter team selection…etc, up to 43 functions.

Multi-Function Output Indication

(DO)

(4 indications )

Include a form C relay contact, a form A relay contact and 2 Open collector output. They can be programmed to

below indications: Drive Operating, Frequency Attained, zero speed, Base Block, Over torque,

Fault Indication, Local/Remote indication, PLC Operation indication, and Auxiliary Motor Output, Drive ready for

use, IGBT over-heat indication …etc, up to 63 functions.

Multi-Function Analog Input

(AI)

AVI: 0 ~ +10VDC((Input impedance 20kΩ), AUI: -10 ~ +10VDC((Input impedance 10kΩ), ACI: 4 ~20mA DC ((Input

impedance 250Ω). 3 different Input terminals can be programmed to 15 functions

Multi-Function Analog Output

(AO)

Include ACO and AVO, They can be programmed to Proportional to output frequency, output current, voltage,

frequency command or motor's speed …etc, up to 15 functions.

Fault Indication

The output will be activated when faults occur (User may get 1 or up to 4 indications from below terminals:2 Relay

contact point RA, RB, RC. or 2 Open-collector

Communication function RS-485 serial port, MODBUS protocol, ASCII & RTU. (Baud rate up to 125 k bps)

Other Functions

PID feedback control, Flying start, Automatic voltage regulation (AVR), 2 accel./decel time selection , Auto-optimu

accel./decel. Time, S-curves, External fault interlock, External fault reset, Auto Restart after fault, 16 Fault records,

Automatic energy–saving, Upper/Lower limit, Programmable pulse output, Password protection, Pump and Fan

process control, Sleep/Wakeup function , Auto-Tuning, By-Pass, Y-Delta control,. Bi-Directional Speed search,

Reverse inhibit, Automatic torque boost & slip compensation, 16-

step PLC run, 16 step preset speed, Coast or ramp

to stop, Random V/F curve, Mechanical brake release control, IGBT/ Heatsink temperature display & Pre-warning,

Quiet operation mode (No noise), User define Multi-function display, Over torque detection, Over current/voltage t

stall prevention, Sink/Source (NPN/PNP) mode, Electronic Thermal Relay, Internal Counter,

in start and stop, Dynamic brake, Controlled cooling Fan, Removable keypad operator, Programmable

Multi-Function DI,DO,AI,AO and Ry terminals.

Intelligent Protection Functions

Self-testing, AC source Over Voltage, Phase loss, Over Voltage, Over Current, Under Voltage, Over Torque,

External Fault, Motor over-load, IGBT Over-temperature, Heat-sink Over-temperature, Electronic thermal, Ground

Fault, Output short circuit, Stall Prevention, Fuse protection, IGBT short circuit , Drive Over Load ,

life monitoring, Auto carrier frequency adjust according temperature, 16 Trip records, Run information of

such like DC-BUS voltage, Output voltage/Frequency/Current, Command frequency, IGBT temperature, Heat-sink

temperature….etc.

Digital Keypad

(PU-02 Digital Keypad with copy

function and PU-03 Digital Keypad

with LCD display are available as an

option)

Eight Function keys: Access R un, Stop, Reset/ Digit Shift, Forward/ Reverse run, Display mode, Keypad Enable,

Programming data and Jog operation…etc.

One Encoder style Fly-Shuttle dial: Sets the parameter number and changes the numerical data

One 6 digits 7 segment display: Display the Setting frequency/actual operation frequency, Output

current/Voltage, motor speed, Fault trip User defined unit(up to 88 type)…etc.

Six LED Display for status indication: Display the Drive run/stop status, Forward/Reverse run status, Keypad

enable, and Frequency command source.

One RJ-45 connector: Removable Keypad, remote control distance up to 150 meters.

Environment

Certificate Complies with CE (EN61800-3) standard

Temperature Ambient: -10 ~ +40 /(℃ ℃ -10 ~ + 50 ) (℃ ℃ Non-Condensing and not frozen). Storage: -20 ~ +60℃ ℃

Humidity

Below 98% R.H. (Non-Condensing)

Vibration Below 20Hz: 1G, above 20Hz: 0.6G

Installation Location Altitude 1,000 m or lower, keep away from corrosive gasses, liquid and dust

* All series in TOPVERT family are designed and manufactured base on CNS and IEC, IEEE, CE & UL standard.

Loading...

Loading...