Maintenance

62

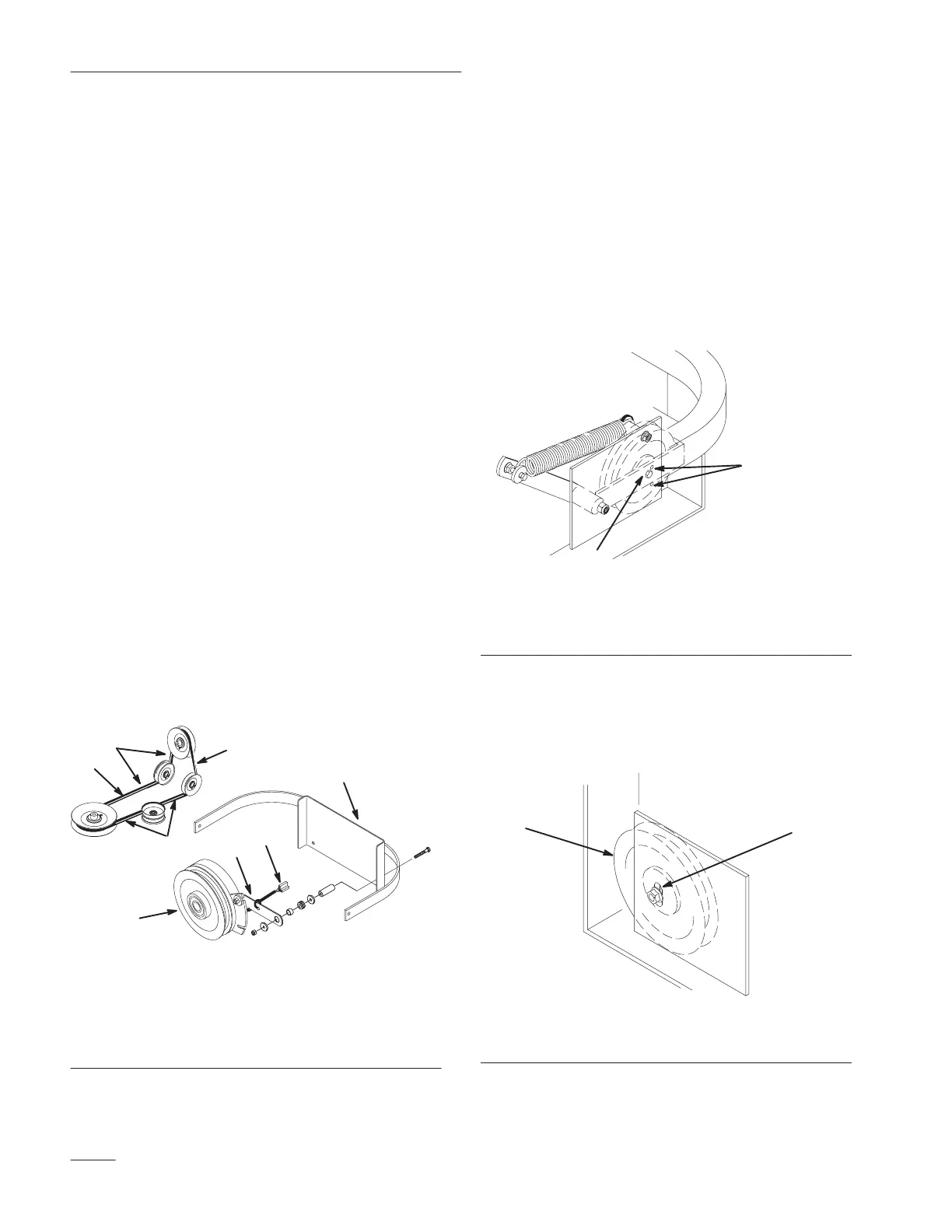

Replacing

the PT

O Drive Belt

Squealing when the belt is rotating, blades slipping

when cutting grass, frayed belt edges, burn marks and

cracks are signs of a worn drive belt. Replace the

PTO drive belt if any of these conditions are evident.

1. Stop the engine, set the parking brake, remove

the key and disconnect the spark plug wire(s)

from the spark plug(s).

2. Remove the clutch retaining strap from machine

frame and unplug clutch terminal from wire

harness (Fig. 52).

3. Remove PTO drive belt from rear idler arm and

front idler pulley assembly. Remove the PTO

drive belt (Fig. 52).

4. Place new drive belt over clutch, around rear

idler pulley, installed into rear idler arm

assembly, installed into front idler pulley

assembly and onto top center pulley (Fig. 52).

IMPORTANT: Check the amount of twist in

belt between pulleys. Make sure it is only

what is specified in figure 52.

5. Install clutch retaining strap and plug clutch

terminal into main wire harness (Fig. 52).

1

4

m–4451

M-4373

3

2

5

7

6

6

Figure 52

1. Clutch

2. Clutch

retaining strap

3.

clutch T

erminal

4. PT

O belt

5.

Machine Frame

6.

1/4’ Belt T

wist

7.

1/8” Belt T

wist

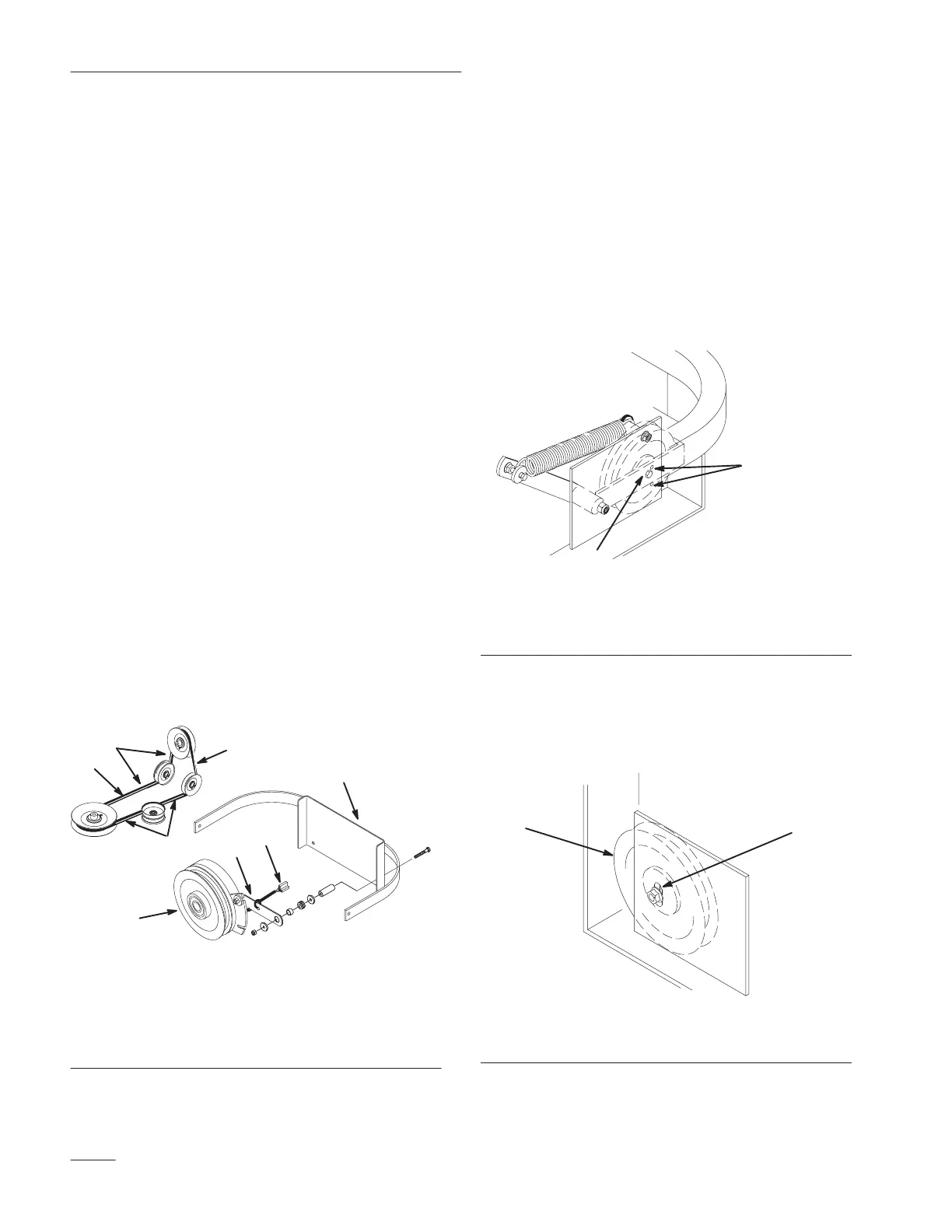

6. Check belt tension. The center bolt of spring

loaded idler must be between the two alignment

holes in left support plate (Fig NO TAG).

Note: Check position of center bolt in Low

Height of Cut. The center bolt must be

at or below the top alignment hole.

Check position of center bolt in a High

Height of Cut. The center bolt must be

at or above the lower adjustment hole

(Fig. 53).

1

2

M-4417

Figure 53

1. Center

bolt, spring loaded

idler

2.

Alignment hole

7. If adjustment is required, loosen the fixed idler

on right support plate and move up or down in

adjustment slot (Fig. 54). To relieve belt tension

lift up on spring loaded idler.

m–3746

12

Figure 54

1. Fixed

Idler

2.

Adjustment slot

Loading...

Loading...