Maintenance

63

8. Check belt tension again. The center bolt of

spring loaded idler must be between the two

alignment holes in left support plate (Fig. 53).

Adjust, if necessary, and tighten all hardware

securely.

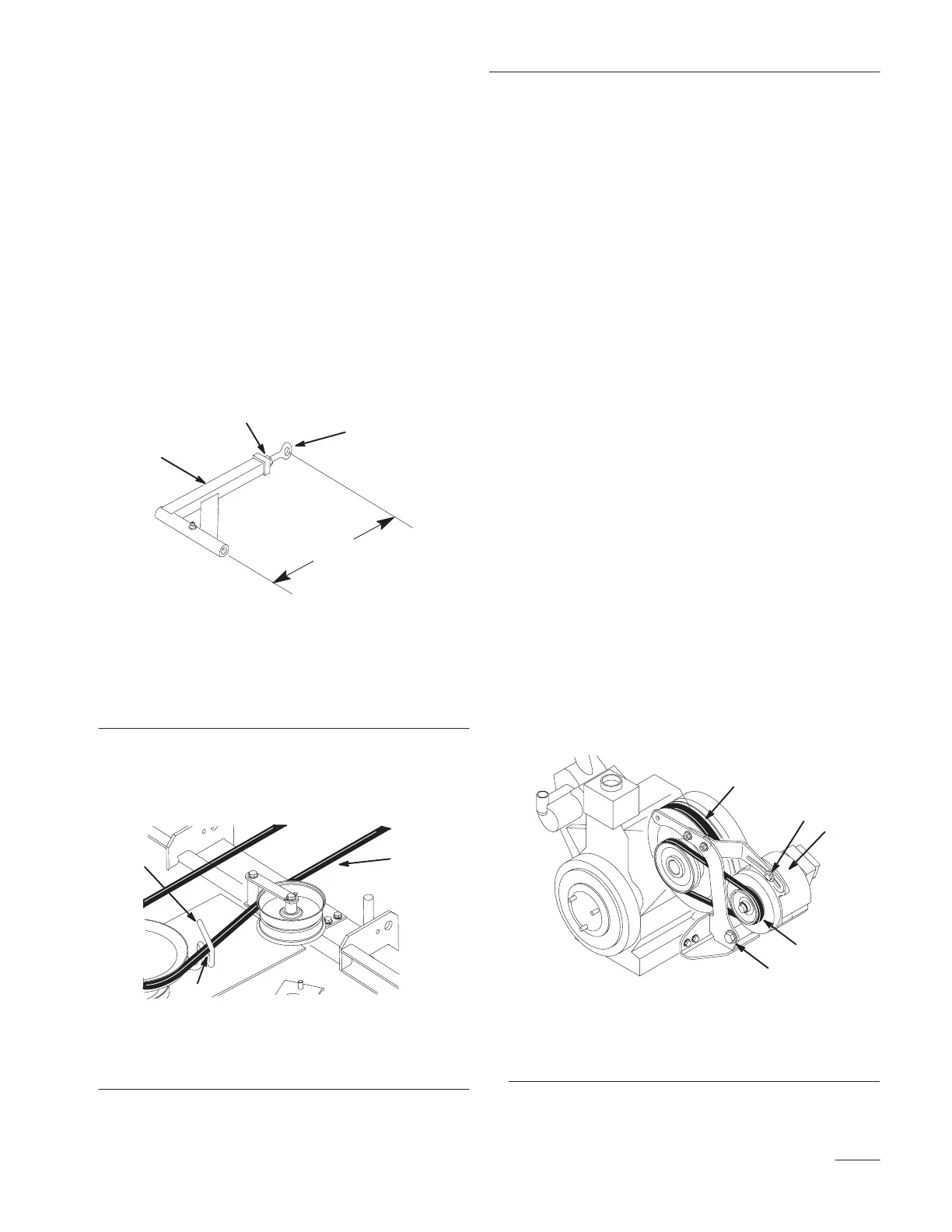

9. If the fixed idler contacts the end of the

adjustment slot and more belt tension is

required, a small change in the lengthen the push

arms can be made (Fig. 55).

10. To lengthen, loosen jam nut and rotate ball joint

counterclockwise, one turn at a time. Adjust

each side the same amount.

m–3740

1

3

2

1

Figure 55

1. Push

arm

2.

15–5/16” (389 mm)

nominal

3.

Jam nut

4.

Ball joint

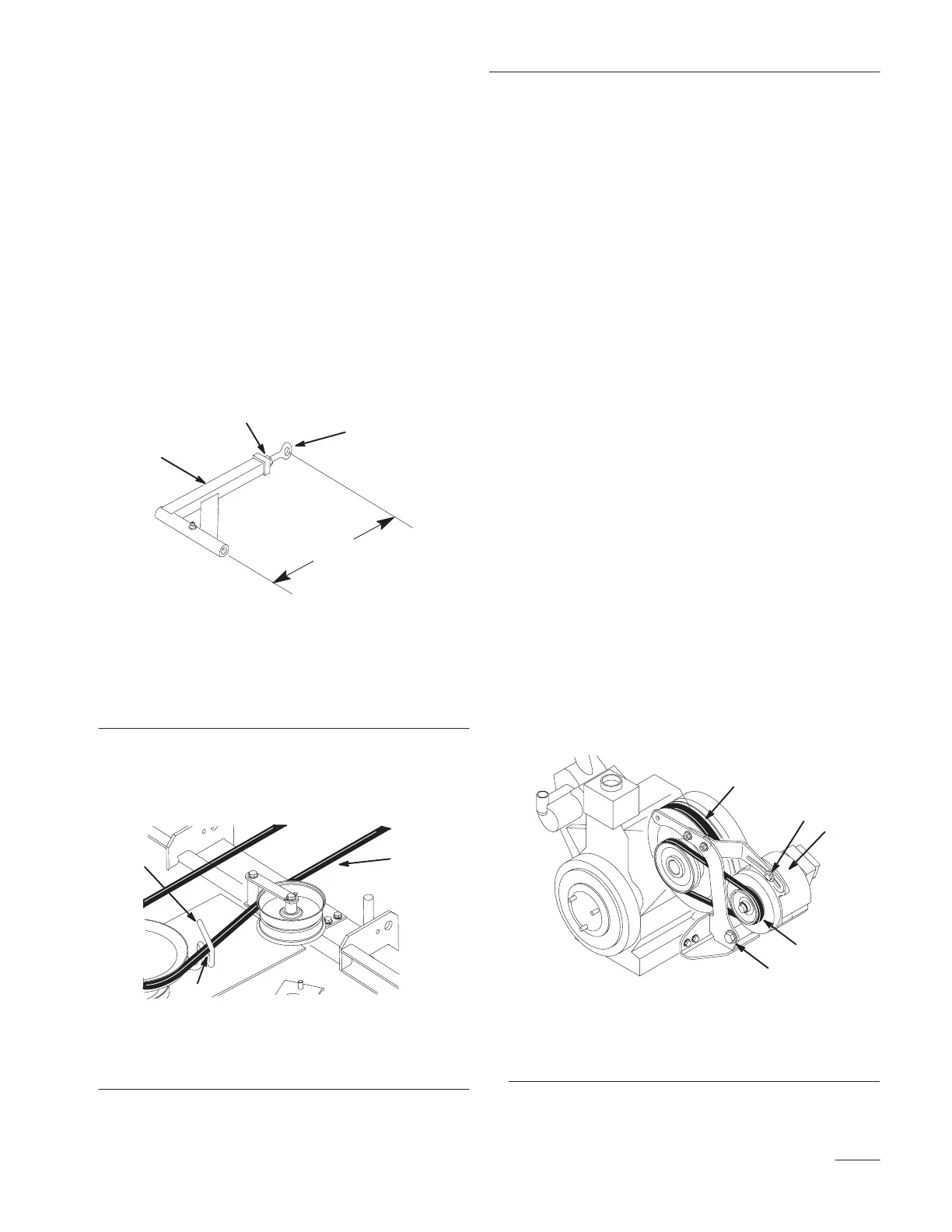

11. Rotate the belt guide, on rear of the mower, so it

is 1/8”–1/4” (3–7 mm) away from the vertical

side of the PTO belt (Fig. 56).

2

M-4374

1

3

Figure 56

1. Belt

guide

2. PT

O Drive belt

3.

1/8”–1/4” (3–7 mm)

Replacing

the Alternator Belt

Squealing when the belt is rotating, frayed belt edges,

burn marks and cracks are signs of a worn belt.

Replace the alternator belt if any of these conditions

are evident.

1. Stop the engine, set the parking brake, remove

the key and disconnect the spark plug wire(s)

from the spark plug(s).

2. Remove the PTO drive belt. Refer to Replacing

the PTO Drive Belt, on page 62.

3. Loosen both upper and lower alternator bolts to

allow alternator to rotate and loosen belt

(Fig 57).

4. Remove belt from pulley, alternator and over

clutch pulley (Fig 57).

5. Install new belt.

6. Rotate alternator out away from engine and

tighten lower and upper aletnator bolts (Fig 57).

Note: Alternator belt will deflect 1/8” while

applying 5–7 pounds of force, when

installed correctly.

7. Reinstall the PTO drive belt. Refer to Replacing

the PTO Drive Belt, page 62.

M-4400

2

1

3

4

5

Figure 57

1. Alternator

2. Upper

Alternator Bolt

3.

Lower Alternator Bolt

4.

Alternator Belt

5. PT

O Drive Belt

Loading...

Loading...