Maintenance Service

Interval

Maintenance Procedure

Every 250 hours

• Replace the primary air lter (more often in dirty or dusty conditions).

• Check the safety air lter (more often in dirty or dusty conditions).

• Change the hydraulic lter and reservoir hydraulic uid when using Mobil® 1 uid

(more often in dirty or dusty conditions).

Every 400 hours

• Grease the caster pivots (more often in dirty or dusty conditions).

Every 500 hours

• Replace the safety air lter (more often in dirty or dusty conditions).

• Replace the spark plug(s).

• Check the wheel lug-nut torque.

• Check the wheel-hub nut torque.

• Adjust the caster-pivot bearings.

• Check the parking-brake adjustment.

• Change the hydraulic lter and reservoir hydraulic uid when using T oro®

HYPR-OIL™ 500 hydraulic uid (more often in dirty or dusty conditions).

Every 2,000 hours

• Change the oil in all 3 gearbox housings and add oil as needed.

Monthly

• Check the battery .

Y early

• Grease the PT O-belt idler arm (more often in dirty or dusty conditions).

• Grease the pump-belt idler arm (more often in dirty or dusty conditions).

• Repack the caster-wheel bearings (more often in dirty or dusty conditions).

• Grease the rear caster wheel hubs (more often in dirty or dusty conditions).

Y early or before storage

• Paint chipped surfaces.

• Check all maintenance procedures listed above before storage.

Important: Refer to your engine owner's manual for additional maintenance procedures.

CAUTION

If you leave the key in the switch, someone could accidently start the engine and seriously

injure you or other bystanders.

Shut off the engine and remove the key from the switch before you perform any maintenance.

Lubrication

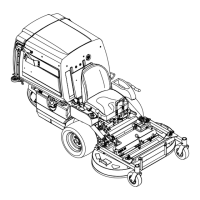

Greasing the Machine

Service Interval : Every 40 hours —Grease the drive

shaft (more often in dirty or dusty

conditions).

Every 100 hours —Grease the mower-deck

ip-up pivot (more often in dirty or dusty

conditions).

Every 100 hours —Grease the mower-deck

push-arm tubes (more often in dirty or dusty

conditions).

Y early —Grease the PT O-belt idler arm (more

often in dirty or dusty conditions).

Grease the machine more often in dirty or dusty

conditions.

Grease T ype: No. 2 lithium or molybdenum grease

1. Park the machine on a level surface, disengage

the PT O, and engage the parking brake.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

3. Clean the grease ttings with a rag.

Note: Scrape any paint of f the front of the

tting(s).

4. Connect a grease gun to the tting.

5. Pump grease into the ttings until grease begins

to ooze out of the bearings.

6. Wipe up any excess grease.

33

Loading...

Loading...