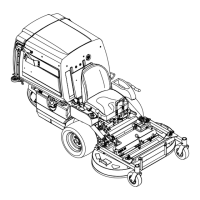

g020525

Figure 55

1. 22.7 to 23.3 cm (8.92 to

9.16 inches)

2. Nuts

9. Engage and disengage the brakes to check for

proper engagement and disengagement. Adjust

if necessary .

Note: When the brakes are disengaged, there

should be little to no free play in the brake

linkage with no dragging in the brakes.

Belt Maintenance

Inspecting the Belts

Service Interval : Every 40 hours

Replace the belt if it is worn. The signs of a worn belt

include squealing while the belt is rotating; the blades

slipping while cutting grass; and frayed edges, burn

marks, and cracks on the belt.

1. Park the machine on a level surface, move the

speed-control lever to the N EUTRAL position,

disengage the PT O, and engage the parking

brake.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

3. T ilt the hopper up and check the pump and PT O

drive belts for wear , cracking, or contamination.

Note: The belts are spring tensioned and no

adjustment is necessary unless the belts are

replaced.

Replacing the PT O Belts

1. Park the machine on a level surface, move the

speed-control lever to the N EUTRAL position,

disengage the PT O, and engage the parking

brake.

2. Shut of f the engine, remove the key , and wait

for all moving parts to stop before leaving the

operating position.

3. With the engine of f, engage the PT O lever , then

remove the hairpin cotter and clevis pin at the

bottom of the PT O-brake band.

4. Rotate the brake band upward and out of the

way of the belts keeping clear of the belt drive.

5. Disengage the PT O lever .

6. Loosen belt guides A and B ( Figure 56 ).

7. Remove the belts.

8. Route the new belts onto the pulleys as shown

in Figure 56 .

50

Loading...

Loading...