Maintenance

49

Check Hydraulic Lines

After every 100 operating hours, check hydraulic

lines and hoses for leaks, loose fittings, kinked lines,

loose mounting supports, wear, weather and chemical

deterioration. Make necessary repairs before

operating.

POTENTIAL HAZARD

• Hydraulic fluid escaping under pressure

can penetrate skin and cause injury.

WHAT CAN HAPPEN

• Fluid accidentally injected into the skin

must be surgically removed within a few

hours by a doctor familiar with this form of

injury or gangrene may result.

HOW TO AV

OID THE HAZARD

•

Make sur

e all hydraulic fluid hoses and

lines ar

e in good condition and all

hydraulic connections and fittings are tight

before applying pressure to hydraulic

system.

• Keep body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic

leaks.

• Safely relieve all pressure in the hydraulic

system before performing any work on the

hydraulic system.

Tire

Pressure

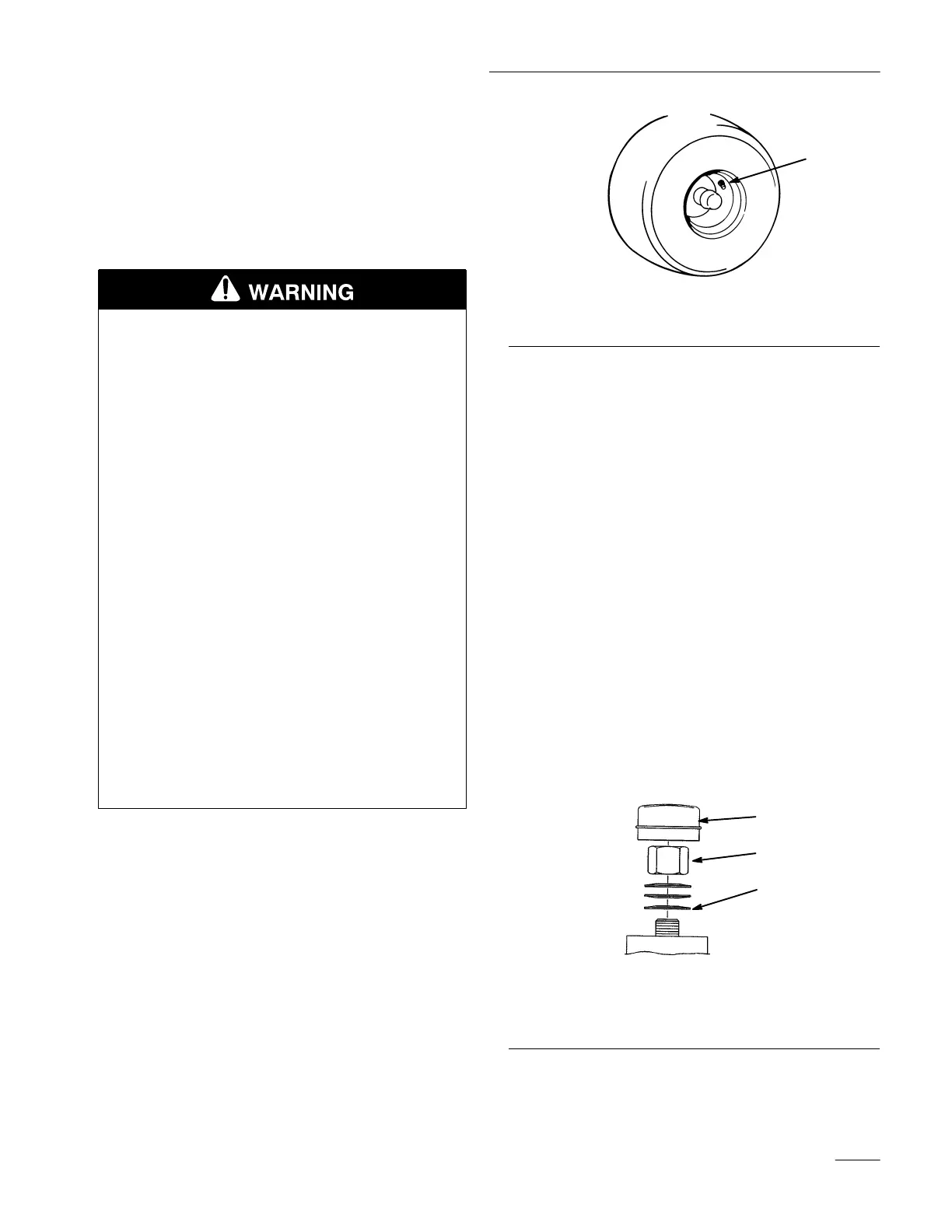

Maintain the air pressure in the front and rear tires as

specified. Uneven tire pressure can cause uneven cut.

Check the pressure at the valve stem after every 50

operating hours or monthly, whichever occurs first

(Fig. 38). Check the tires when they are cold to get

the most accurate pressure reading.

Pressure: 13 psi (90 kPa) drive wheels and castor

wheels.

1

m–1872

Figure 38

1. Valve

stem

Castor

Pivot Bearing

Adjustment

Check after every 500 operating hours or at storage

which ever comes first.

1. Stop the engine, set the parking brake, remove

the key and disconnect the spark plug wire(s)

from the spark plug(s).

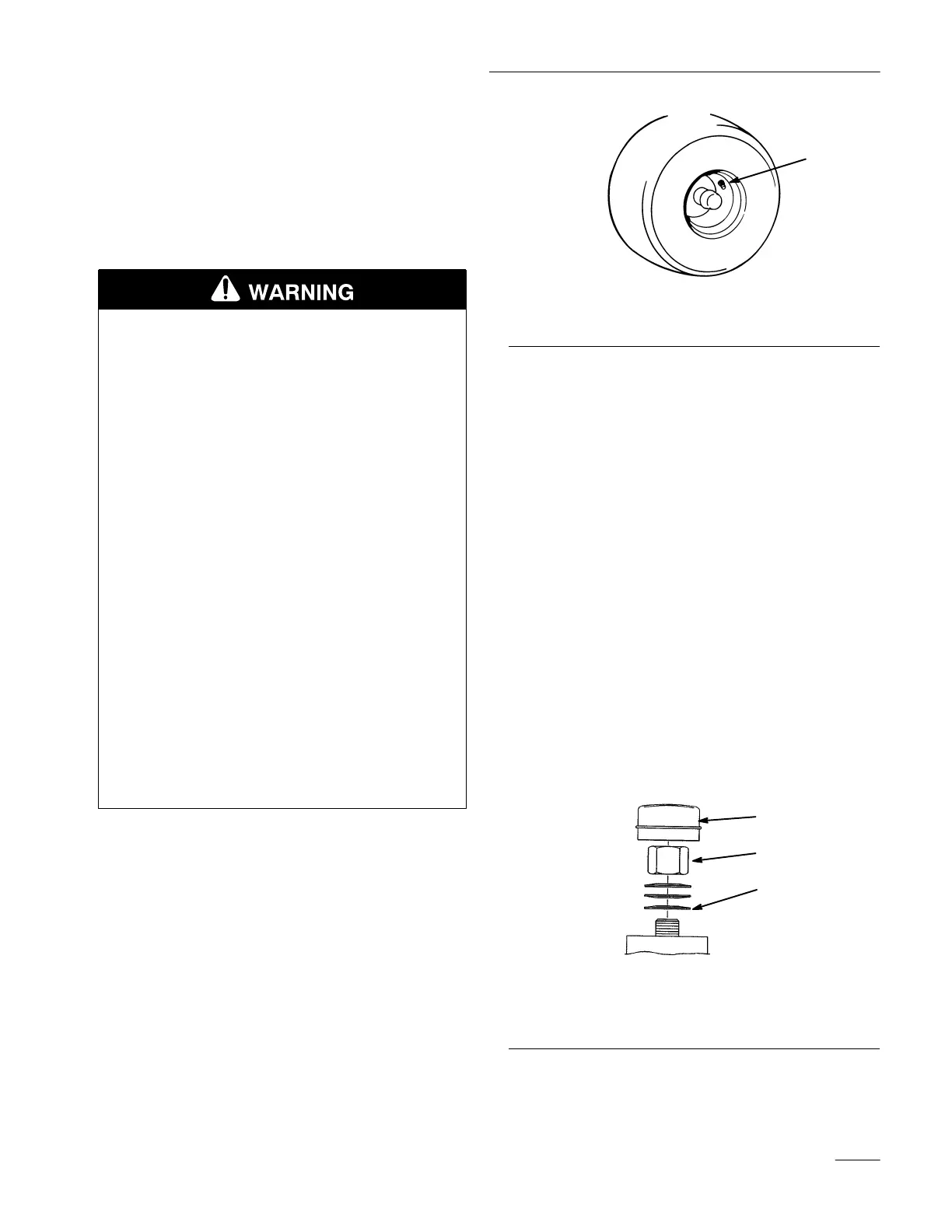

2. Remove dust cap from castor and tighten lock

nut (Fig. 39).

3. Tighten until spring washers are flat and then

back off a 1/4 turn to properly set the pre–load

on the bearings (Fig. 39).

IMPORTANT: Make sur

e spring washers ar

e

installed correctly as shown in figure 39.

1

2

3

Figure 39

1. Spring

W

ashers

2.

Lock Nut

3.

Dust Cap

Loading...

Loading...