Do you have a question about the Toshiba RAV-SP1604AT8-E and is the answer not in the manual?

Provides original instructions and defines key terms.

Details the necessary qualifications for installation and service personnel.

Specifies necessary protective gear for various work tasks.

Explains safety indications like DANGER, WARNING, CAUTION, and illustrated marks.

Lists and explains warning labels found on the air conditioner unit.

Outlines critical safety precautions for operation and maintenance.

Provides user explanations, conformity declarations, and disposal guidelines.

Details R410A refrigerant properties, safety, and handling precautions.

Lists essential tools and equipment for R410A refrigerant systems.

Detailed technical specifications for various indoor unit types.

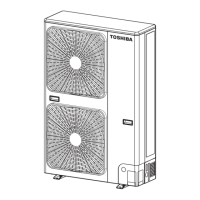

Detailed technical specifications for outdoor units.

Graphical representation of cooling and heating operation characteristics.

External views and dimensional data for the outdoor unit.

Illustrates the refrigerating cycle diagram of the outdoor unit.

Provides wiring diagrams for the outdoor unit.

Lists specifications for electrical components of the outdoor unit.

Covers R410A refrigerant properties, safety, and handling.

Guidelines for installing and processing R410A refrigerant piping.

Details required tools and procedures for refrigerant handling.

Information on brazing materials, flux, and methods.

Procedures and restrictions for reusing existing refrigerant pipes.

Final checks required for piping after installation.

Guidance on handling existing pipes and recovering refrigerant.

Covers pre-installation prep, pipe length, airtight tests, air purge, wiring, earthing, and test runs.

Guidelines for selecting installation location and required clearance space.

Procedures for installing the outdoor unit base and connecting piping.

Instructions for connecting and tightening refrigerant pipes.

Procedures for air purging and performing airtight tests.

Guides on valve operation and requirements for refrigerant replenishment.

Guidelines and safety precautions for electrical wiring.

Importance of earthing and steps for conducting a test run.

Functions requiring local implementation and handling existing pipes.

Supplementary information on piping reuse and pipe curing methods.

Overview of the outdoor unit's control systems.

Explanation of primary control functions like PMV and temperature release.

Details on how the outdoor fan speed is controlled in cooling and heating.

Controls for coil heating, preventing short cycles, and current limits.

Functions for current release value shifting and high-pressure protection.

Control logic for defrost operations and high-pressure switches.

Summary of troubleshooting steps for wired remote controller systems.

Summary of troubleshooting steps for wireless remote controller systems.

Method for diagnosing errors based on unit LED indications.

Troubleshooting for issues not identified by standard check codes.

How to use the remote controller's monitor function for sensor data.

List of check codes and their corresponding causes for outdoor units.

Identifies error modes and causes detected by indoor units.

Identifies error modes and causes detected by outdoor units.

Troubleshooting for communication errors between controllers.

Step-by-step diagnostic procedures for outdoor unit check codes.

Procedure to call error history and configure group control.

Describes the sequence of operations during indoor unit power-on.

Covers DIP switch and jumper settings for outdoor unit functions.

Utilizing LEDs and switches for maintenance checks.

Selecting LED displays and interpreting error codes.

Displaying sensor values, current, frequency, and PMV opening.

Guidelines for regular maintenance and unit checks.

Procedure for replacing the service P.C. board.

Step-by-step procedure for exchanging the compressor.

Procedures for detaching and attaching outdoor unit components.

Procedure for removing and installing the inverter assembly.

Procedure for replacing the interface control board (MCC-1599).

Procedure for replacing the Fan IPDU board (MCC-1597).

Procedure for replacing the noise filter board (MCC-1600).

Procedure for replacing the compressor IPDU board (MCC-1596).

Procedure for replacing the fan motor.

Steps for removing compressor leads and refrigerant pipes.

Procedure for mounting a new compressor and vacuuming the system.

Procedures for replacing the PMV coil and fan guard.

Exploded view diagram and parts list for the outdoor unit.

Exploded view diagram and parts list for the inverter unit.

Critical checks for refrigerant concentration limits in rooms.

| Brand | Toshiba |

|---|---|

| Model | RAV-SP1604AT8-E |

| Category | Air Conditioner |

| Language | English |

Loading...

Loading...