Graphic 7

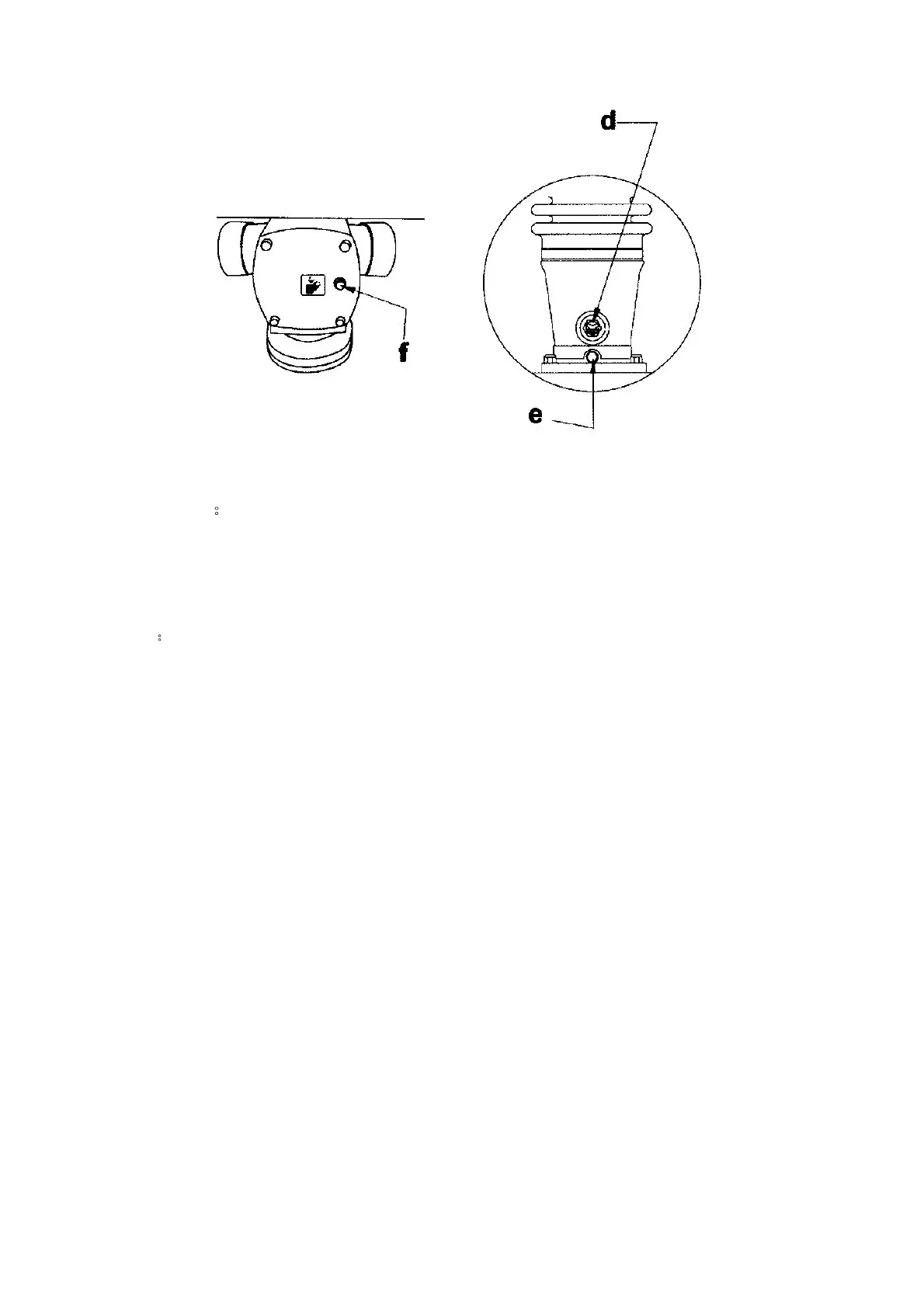

Oil change:

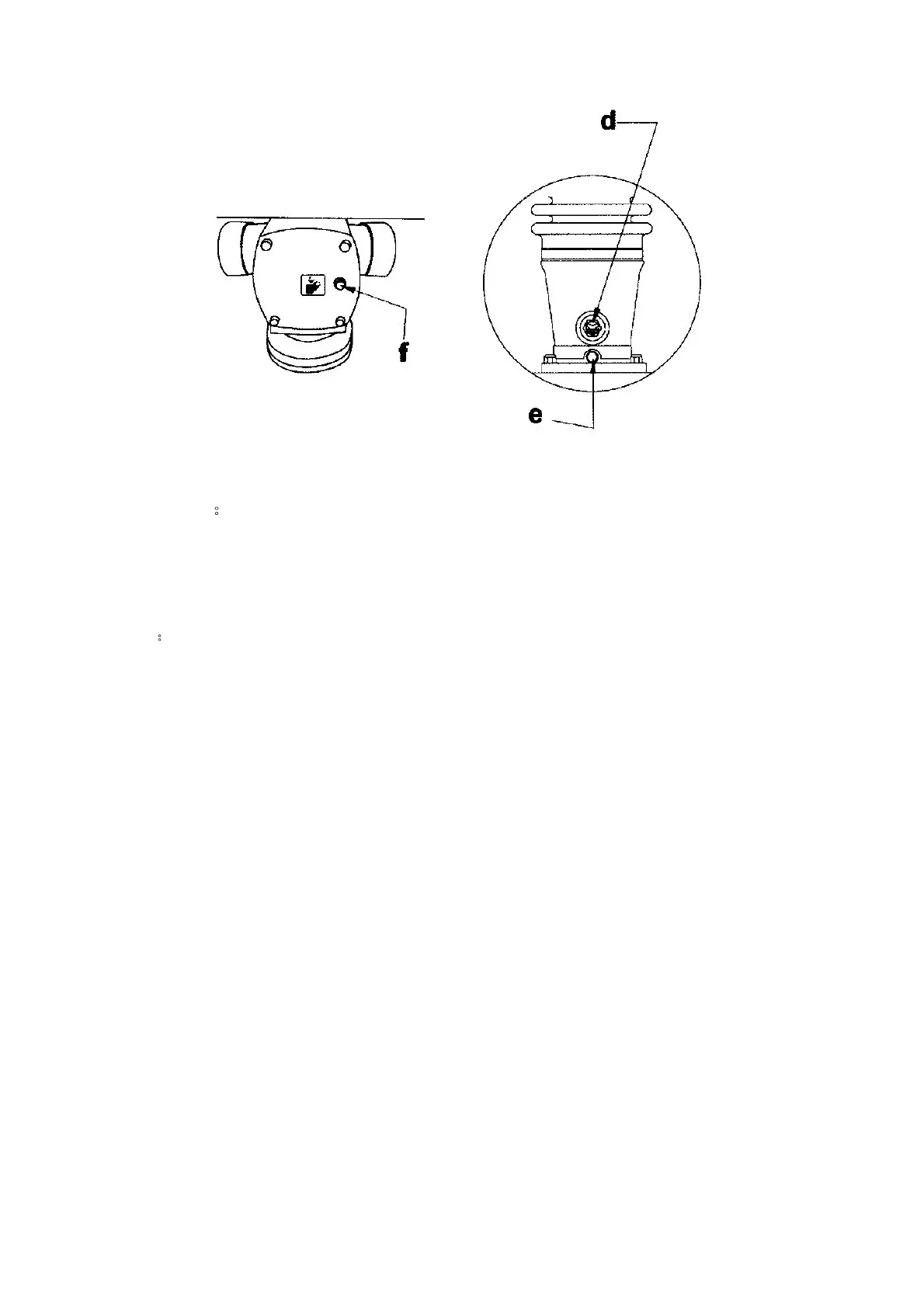

6.4.5 Unscrew the oil drain plug (e) located below the oil sight glass.

6.4.6 Tip the rammer back until it is resting on its handle and allow oil to drain.

Note:In the interests of environmental protection,place a plastic sheet and a container

under the machine to collect any liquid which drains off.Dispose of this liquid in

accordance with environmental protection legislation.

6.4.7 Screw in the oil drain plug (e).Torque to 54 Nm.

6.4.8 Remove filling oil plug (f) and fill with oil.See Technical Data for oil quantity and type.

Wrap the filling oil plug with Teflon tape.Install the filling oil plug (f).Torque to 9 Nm.

6.5 Shoe Hardware

See Graphic 8

On new machines, or after replacing shoe,check and tighten shoe hardware (a) after the first

5 hours of operation.Inspect hardware every week thereafter.

Torque hardware as specified.

Loading...

Loading...