Wired to

Vehicle

Battery:

Connect

the power

wire to the

vehicle

battery

and to

Endurance II. A 0.5A fuse (not

provided) should be used between

the power cable and positive battery

terminal when connecting directly to

a battery.

Endurance II is polarity independent,

so it cannot be installed backwards.

Use zip-ties to secure the cable to

the bike as

it is routed to Endurance II.

System Tap: The possible points to

tap into the vehicle electrical system

are at the lights, ignition, or CDI.

When tapping into the electrical

system, connect to a circuit protected

by fuse. It is best to connect so

power is not interrupted by key

switch.

MX Bikes: Motocross bikes do not

have 12 volt power. For connection

to an MX bike, connect power leads

to ignition power leads from stator.

Use caution, as this is a high voltage

option.

Endurance II will operate in the range

of 9.0-55VDC/9.0-400VAC, but will

not draw enough power to drain a

vehicle battery.

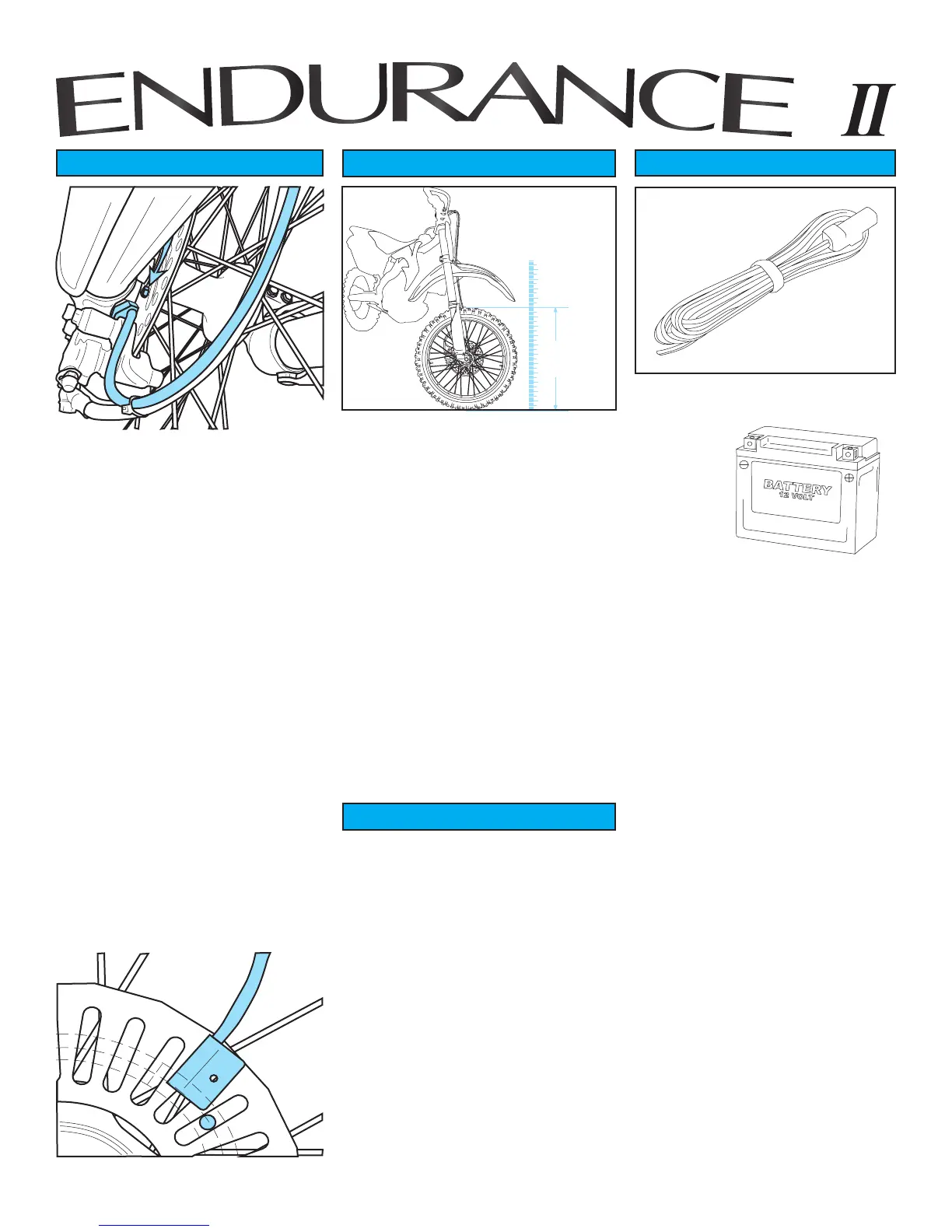

Motorcycles & ATV’s require a magnet

placed on a rotating surface such as

the front or rear wheel and a sensor

opposite the magnet to create a wheel

sensor pick up.

Magnets are offered in a variety

of options such as a magnetic

replacement rotor bolt, or a small

neodymium magnet you can adhere to

a rotating surface.

The wheel sensor is best installed

allowing the wheel sensor lead to

route along side the front or rear

brake lines to prevent damage during

riding as well as a clean wire routing

installation.

Most motorcycles & ATV’s require

a model specic wheel sensor and

magnet application. Refer to provided

installation sheet insert for properly

installing your wheel sensor and

magnet.

Magnet About to Pass Under Sensor

Optimum Magnet Rotation Path

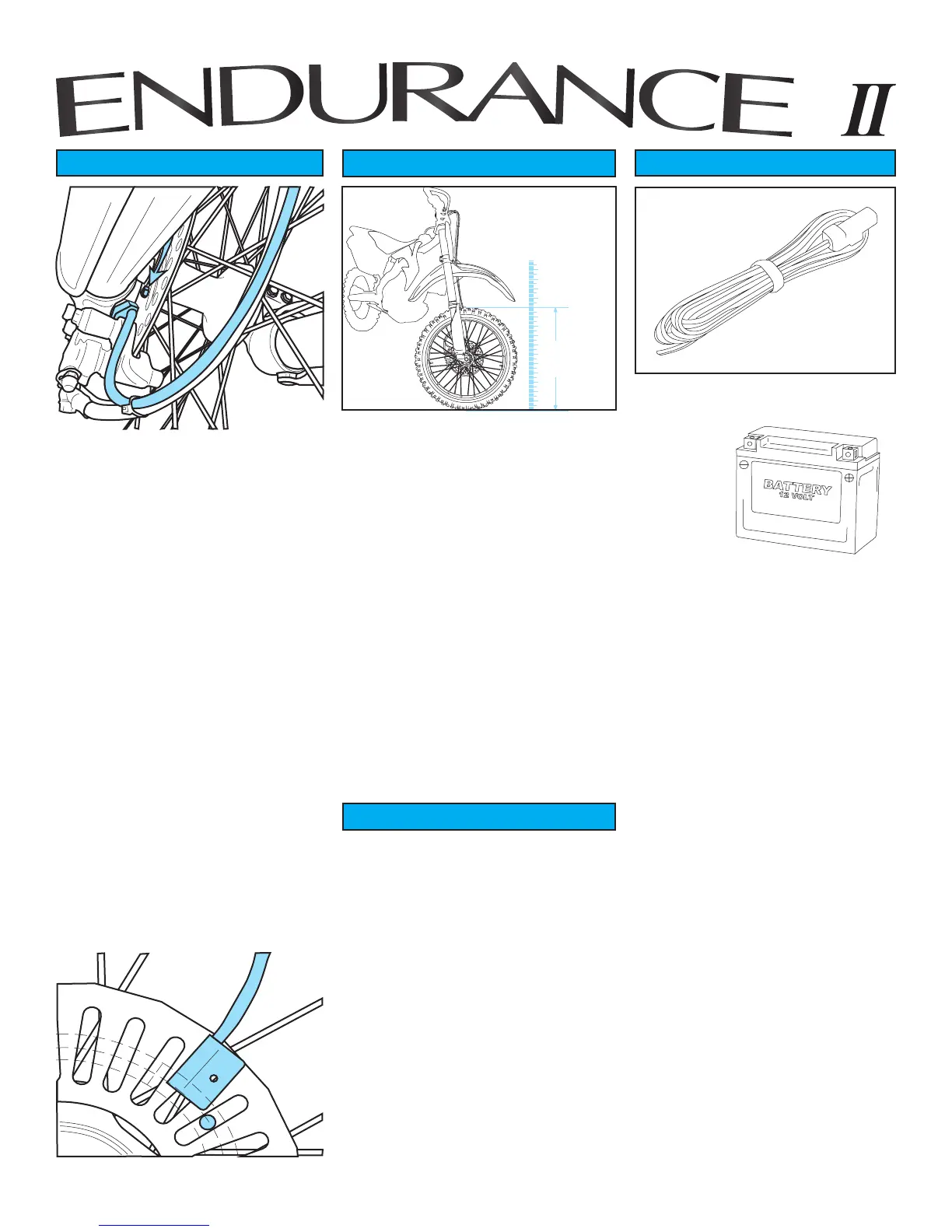

Method 1: Ruler Measurement MethodMotorcycle Sensor/Magnet Installation

Wheel Size=

Wheel Diameter(mm)

x 3.14

Diameter(mm)

x 3.14

Taking Wheel Measurement

Find the diameter of the wheel being

used during installation in millimeters.

Take the diameter and multiple it by

3.14 to identify the wheels rolling

circumference. The diameter in

millimeters is the value you will use as

your tire size. Enter this number during

your initial set up.

Note: Although any rotating surface

can be used to measure wheel speed

the front wheel is the easiest method

of installation. If you measured the

diameter of your wheel in inches,

rst multiply your diameter by 25.4

to convert it into millimeters. Once

converted follow the instructions

outlined in the previous section to

complete this process.

Method 2: Rolling Measurement

On a at surface, mark the tire sidewall

and the ground with a marker or piece

of chalk. Roll the wheel until the mark

on the tire has made one 360 degree

rotation and is lined up to the ground.

Mark this location on the ground lining

up to the mark on the tire sidewall.

Measure the distance between the

two marks made on the ground. If this

measurement is in inches multiply your

measurement by 25.4 to convert it into

Millimeters. If your measurement is

in millimeters discard this conversion

process. The measurement taken in

the rolling circumference of your wheel

and will be used as your tire size during

initial set up mode of you computer.

Power Wire

Power Wire Installation

Loading...

Loading...