18-HE58D1-5 11

Installer’s Guide

MEASURING AIR FLOW

1. Equipment Required

-

A magnahelic guage or other device capable of mear-

suring 0 to 1.0 in. water of differential pressure.

2 pieces of natural rubber latex tubing, 1/8" ID, 1/16"

wall works best.

NOTE: Be sure to remove cap from pressure port

before inserting tubing. Insure tubing is well seated

in pressure ports.

NOTE: The tubing should extend in the pressure

port approximately 1 inch.

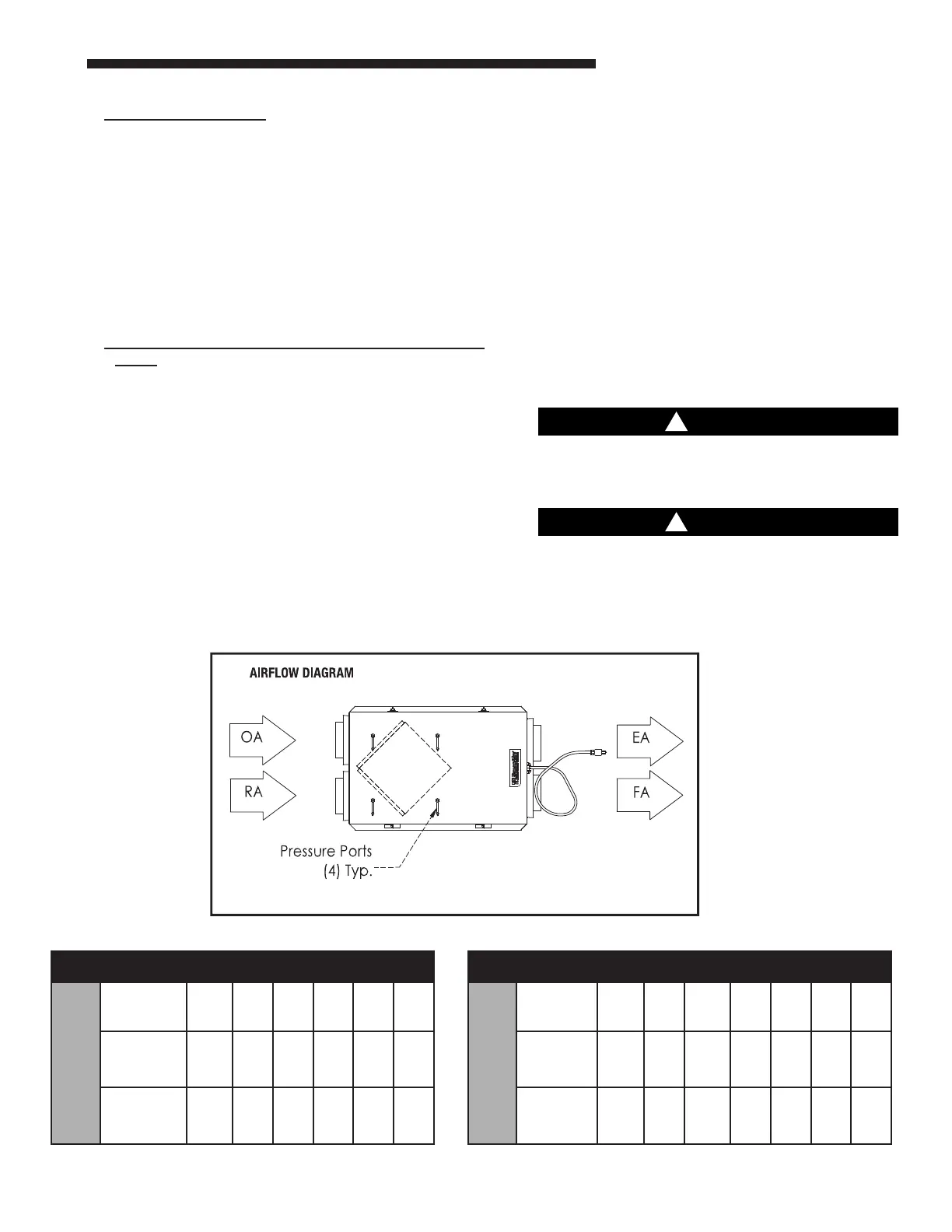

2. Cross Core Static Pressure Measurement Instruc-

tions

- The individual differential static pressures

(DP) are measured using the installed pressure ports

located in the front of the units core access doors.

NOTE: These ports are carefully located on the unit

to give the most accurate airflow measurement.

Do not relocate pressure ports.

To read SCFM of Fresh Air (FA) install the "high"

pressure side (+) of your measuring device to the

Outside Air (OA) port and the "low" pressure side (-)

to the Fresh Air (FA) port.

To read SCFM of Room Air (RA) install the "high"

pressure side (+) of your measuring device to the

Room Air (RA) port and the "low" pressure side (-) to

the Exhaust Air (EA) port.

If guage drops below zero, reverse tubing connec-

tions.

Use the reading displayed on your measurement

device to cross reference the CFM output using the

conversion chart

NOTE: Be sure to replace cap into pressure port

when airflow measuring is completed.

NOTE: For best performance the airflow rate for

both the Fresh Air and the Exhaust Air should

be roughly equal ("balanced"). In some facilities a

slight positive or negative pressure in the building

is desired. Envirowise energy recovery ventilators

can generally operate with a flow imbalance of up

to 20% without significant loss in energy recovery

efficiency.

Make sure clean filters are installed before balanc-

ing air flow. Dirty or clogged filters reduce airflow

through the unit.

The proper airflow range for the models are:

EERVR100A1P00BA: 50-140 CFM

EERVR200A1P00BA: 100-200 CFM

EERVR300A1P00BA: 150-300 CFM

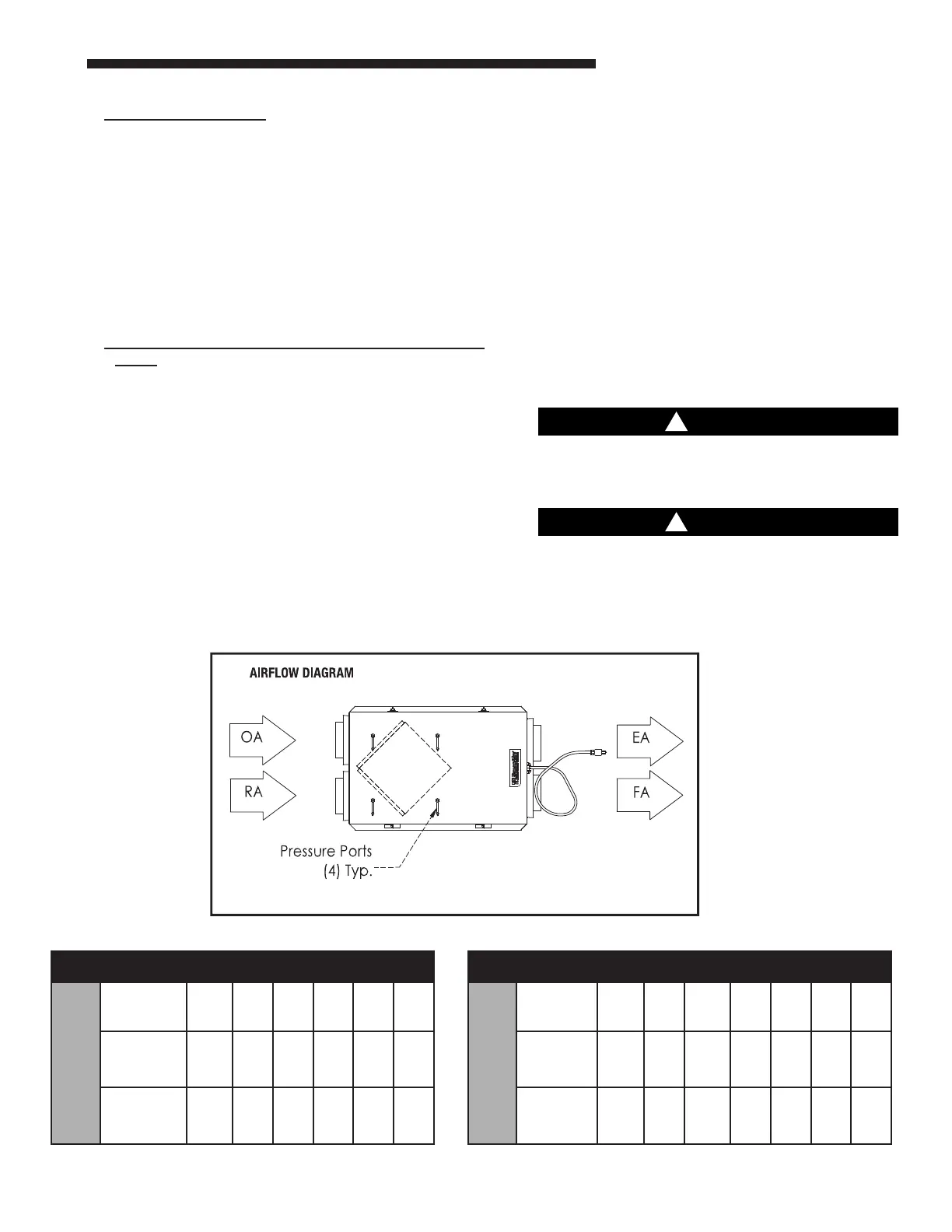

Differential Static Across Core DSP vs. CFM

EERVR100

DSP 0.10 0.20 0.30 0.40 0.50

Fresh Air

(FA)

CFM 28 57 85 113 142

Room Air

(RA)

CFM 28 57 85 113 142

Differential Static Across Core DSP vs. CFM

EERVR200

EERVR300

DSP 0.10 0.20 0.30 0.40 0.50 0.60

Fresh Air

(FA)

CFM 59 119+ 178 238 297 356

Room Air

(RA)

CFM 59 119+ 178 238 297 356

Loading...

Loading...