2. Cooling System

Use only automotive grade antifreeze and distilled water in cooling system.

Do not use water that contains salt or alkalis (Tap Water)! Using non-distilled

water creates scale in the radiator, causing corrosion and premature wear.

You must check and maintain all fuel, lubricant and coolant levels. Not doing so will accelerate and

shorten the life of the standby system. Attention must be paid to all fluid systems and annually

serviced by an authorized service provider or call 844-367-5660 for assistance.

Converting from Natural Gas (NG) to Liquid Propane Gas (LPG)

Most generators are configured for natural gas operation at the factory. Switching over to LP

Vapor is a simple procedure.

3. Fuel Conversion

Do not touch hot engine parts. The engine and exhaust system

components become extremely hot during operation.

Two fuel connections on the fuel block allow field conversion between natural gas (NG) and Liquid Propane

(LPG). The fuel metering valves are factory-set and sealed to provide the best possible hot and cold starting.

Use the following procedure to convert fuel from type to another.

Natural Gas (NG) and Liquid Propane (LPG) Conversion.

• Use a pressure reducing valve to reduce LP pressure supply as needed.

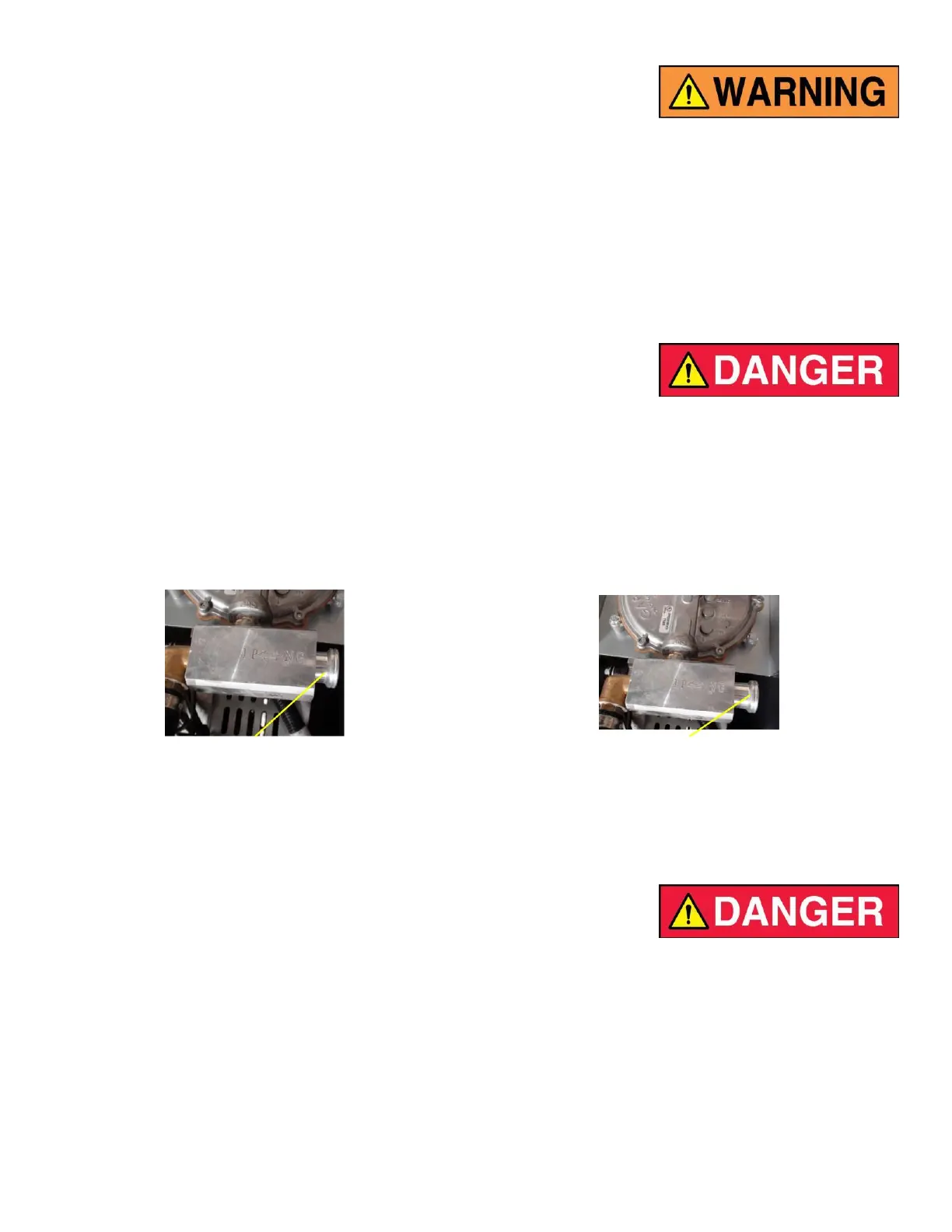

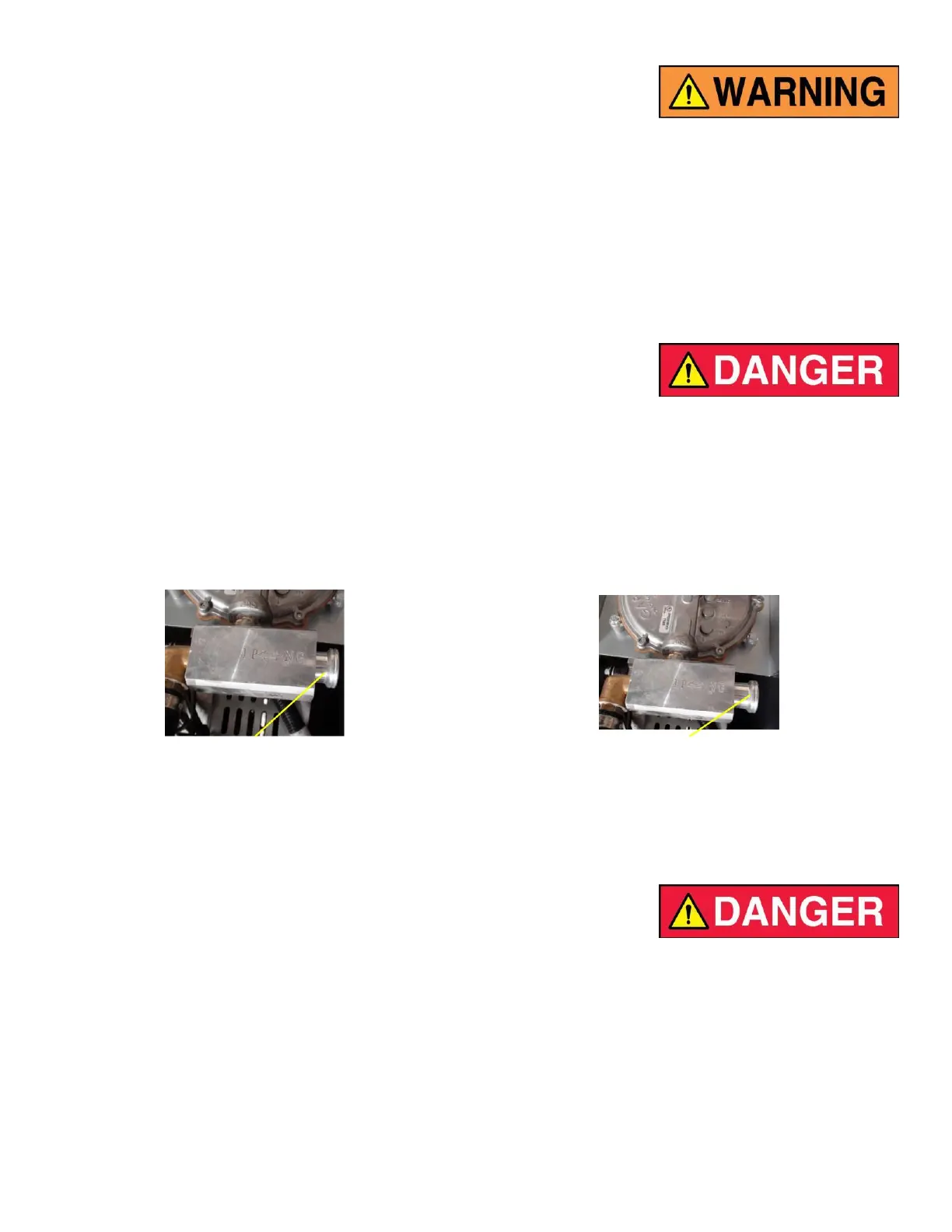

• Push or pull the pin located above Regulator as pictured below, for desired fuel type.

LPG NG

A. Liquid propane (LPG)

For engines set up to run on Liquid propane, please check the fuel supply pressure, lower or higher-

pressure range will result in equipment failure. Inlet pressure 1.7kPa to 3.5kPa, and gas line should

be no longer than 16 feet or 5 meters, the inner diameter shall not be less than (0.63”) or 16mm.

It is strictly prohibited to remove high pressure gas lines during operation,

service and repair. Contact your service provider. You must check and test for

gas leaks using a gas leak detector before use. The observation time is not

less than 1 minute per connection. Based on different gas sources that are available, there may be

different gas pressures present. Make sure pressure is known before installation. A pressure

reducing valve may be re-quired to obtain optimal requirements. You will need to use a pressure

reducing valve if the pressure is excessively high. Additional parts and tools such as leak detectors

and pressure gauges are not included with this purchase.

16 15 032-5095-1A-EN

Loading...

Loading...