Trident 88 Owners Manual 35

Trident 88 Master Channel Recall Sheet

Trident 88 Fader Care and Maintenance

Level 1

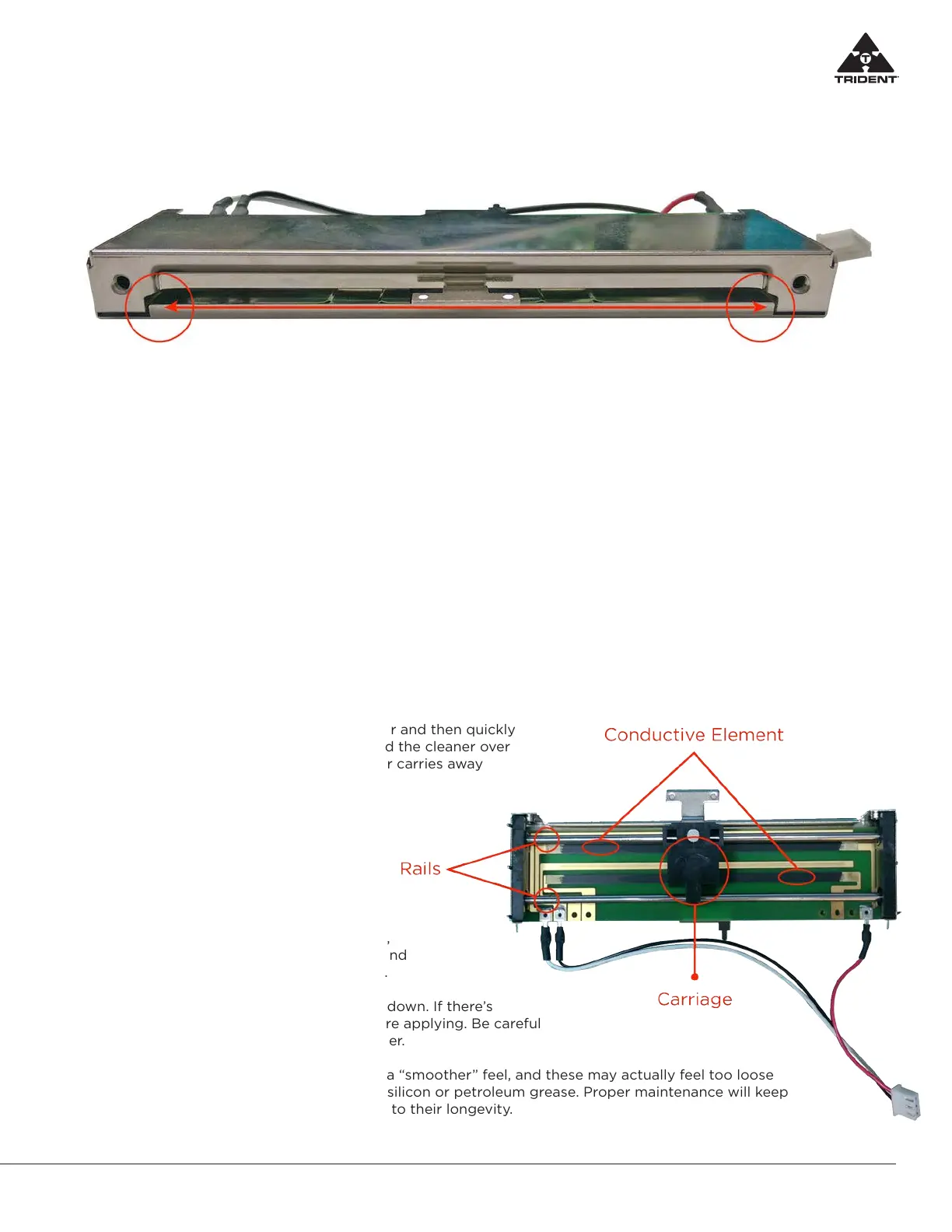

The fir t step is to use compressed air to blow as much dirt as possible out of the fader.

Figure 1: Start by blowing one end, and then the other. There is usually dust or debris in the fader that will come out easily,

and this usually would be all that is needed in terms of cleaning. Move the fader carriage to one end and blow air into the

slot aiming away from the carriage so that dust can escape through the slot. Then move the carriage to the opposite end

and blow air aiming the opposite way.

Using off the shelf cleaner/lube spray on the fader can actually worsen its condition, and it’s likely that the dust and debris

will be matted down and stick in the corners. This is not recommended for service. A fader might seem to work better for

a while using a cleaner/lube spray, but this won’t last and might lead to the need for a more substantial (and time consum-

ing) cleaning eort.

Note: Compressed air must be clean and dry. If an air compressor isn’t available, cans of aero-duster will work,

but they don’t last long

Level 2

If the initial “blowing out” process didn’t oer the desired results, it’s time to move on to use of chemical contact cleaner.

Some faders have lubricating grease applied by the manufacturer, while others employ a self-lubricating Teflon-type of

plastic. If used sparingly, chemical contact cleaner shouldn’t impact the self-lubricating type, but it will invariably wash

away lubricating grease. The goal is to avoid adding any more lubrication than is absolutely necessary - dust tends to fall

away from dry surfaces, but it sticks to oily surfaces.

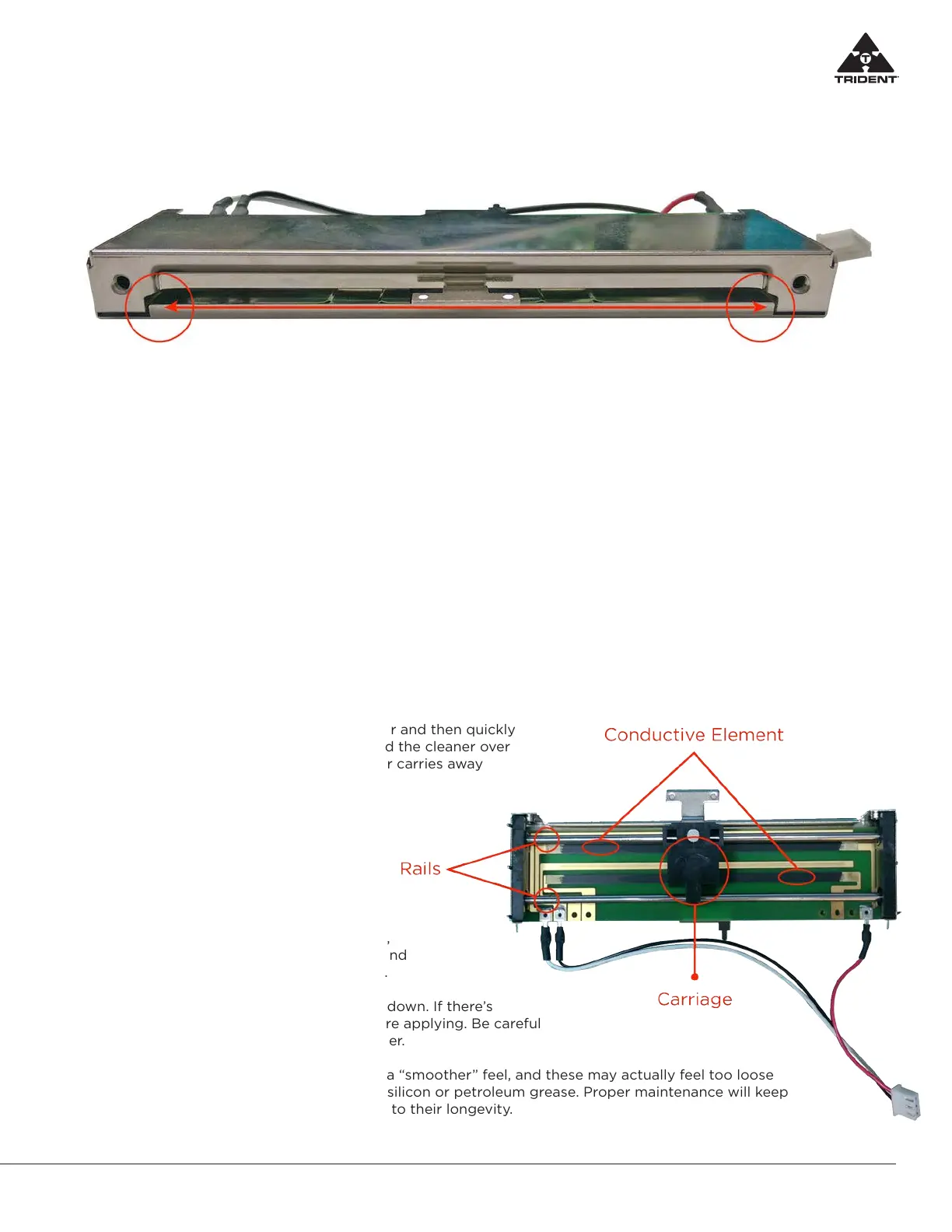

After spraying contact cleaner, exercise the fader and then quickly

blow out the excess cleaner. This helps to spread the cleaner over

the entire fader surface, while the excess cleaner carries away

additional loosened dirt.

Level 3

The fader is still feeling a little rough?

Time to try a little lubrication. The key word is

“little” – use as little as possible. Depending on

the type of fader, use a precision dropper to

place just a few drops of lubrication in the fader,

or give it just a quick squirt. Exercise the fader and

then blow away the excess with compressed air.

Some oils react with plastic, causing it to break down. If there’s

any doubt, test it out on a spare fader fir t before applying. Be careful

not to damage the wiper, which can ruin the fader.

Certain faders use thicker grease that results in a “smoother” feel, and these may actually feel too loose

after lubrication. If this proves bothersome, use silicon or petroleum grease. Proper maintenance will keep

faders performing well for years and is essential to their longevity.

Loading...

Loading...