10

GB

Troubleshooting

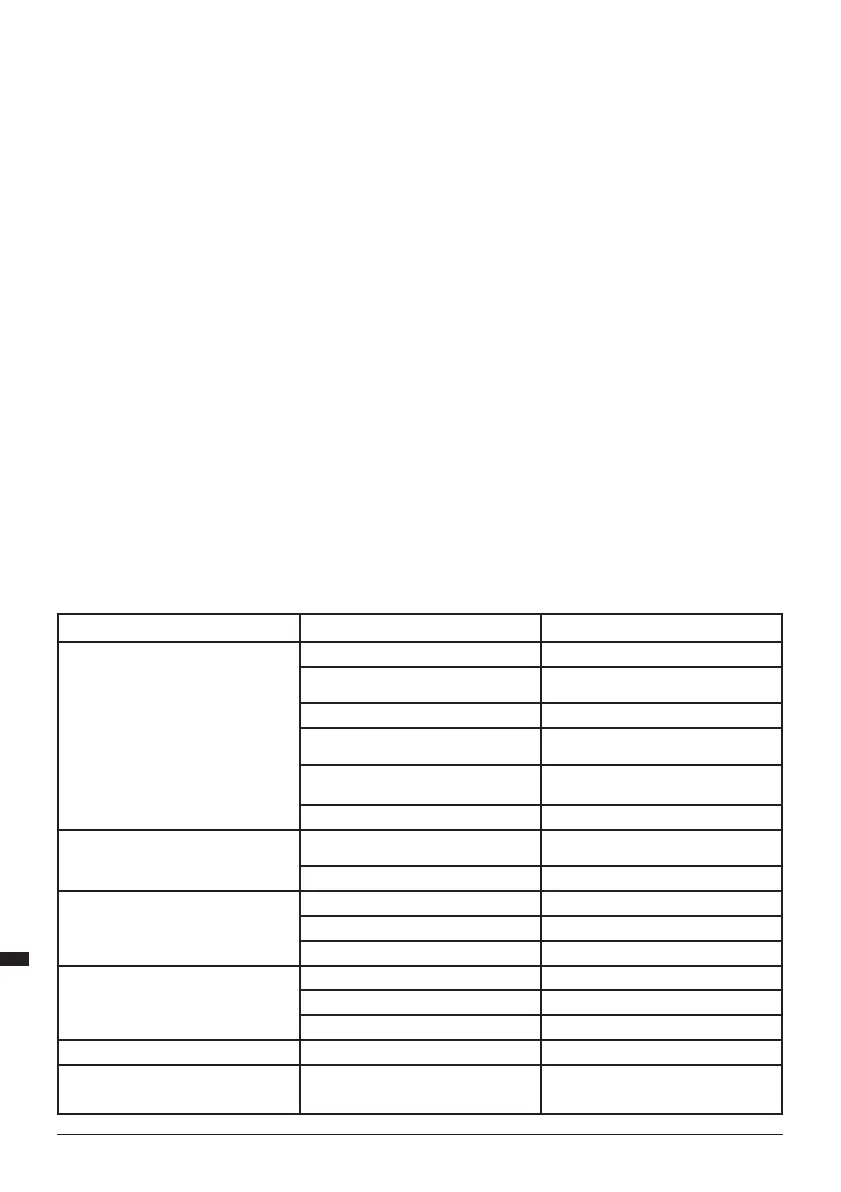

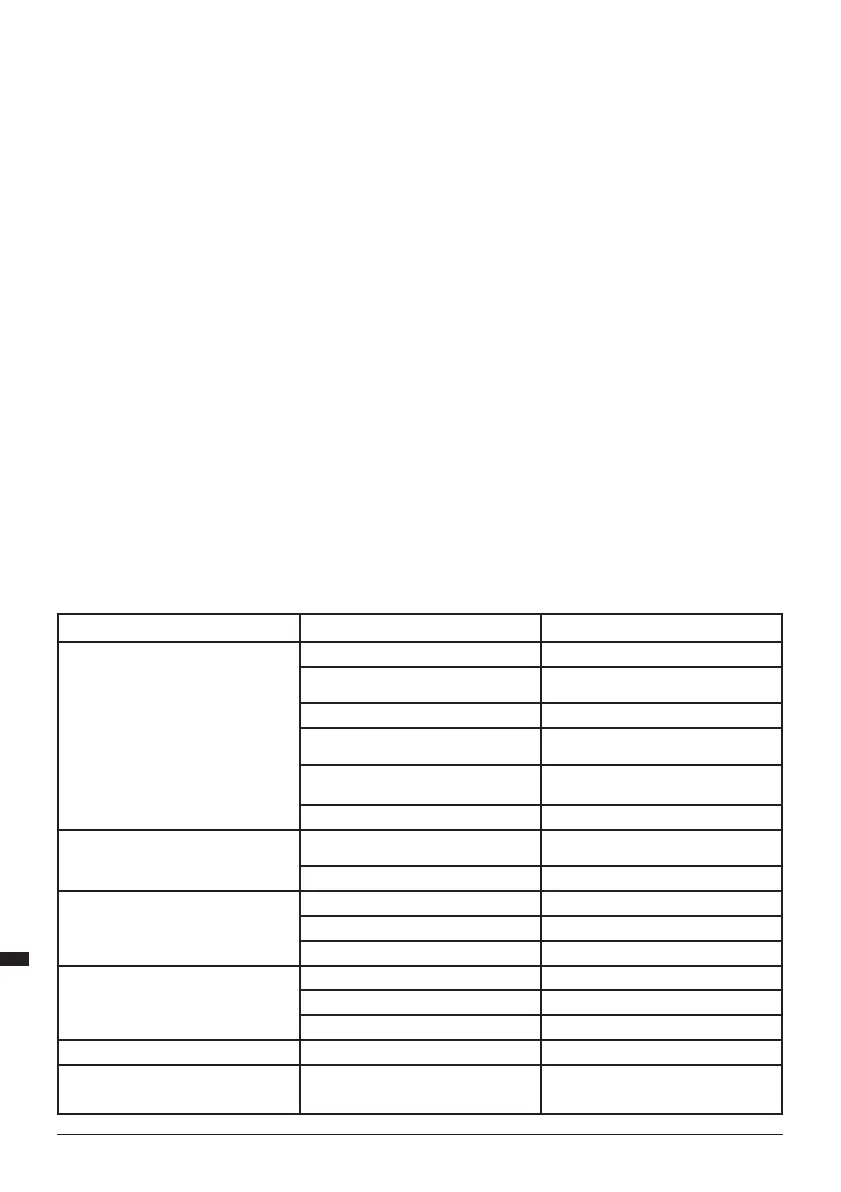

Symptom Possible Cause Solution

No power

Mains plug not inserted into socket or switched on Plug in and switch on

Fuse blown in plug or circuit breaker tripped in consumer

unit

Replace fuse or reset circuit breaker

RCD connected and not reset Reset RCD

Extension lead overloaded and thermal protection has

operated

Replace extension lead or unwind cable fully from reel to

allow maximum current use and reset thermal protection

Power lead or power lead connection to tool or mains

plug damaged

Requires repair at an authorised Triton service centre

Power tool fault Requires repair at an authorised Triton service centre

Motor does not start

Carbon brushes worn Brushes need replacing by an authorised Triton service

centre

Power tool fault Requires repair at authorised Triton service centre

Rough finish on wood after planing

Worn blade or blades Replace all blades

Damaged blade or blades Replace one or more blades

Wood is wet Allow wood to dry

Depth of cut incorrect

Worn or damaged blades Replace blades

Poorly fitted blade or blades Re-fit blade or blades

Incorrect blades fitted Replace blades with correct type

Barrel not rotating

Broken drive belt Replace belt

Vibration or abnormal noise

STOP using tool immediately Re-check all user accessible parts are secure and correctly

fitted first and if not solved contact an authorised Triton

service centre

WARNING: If the blades protrude or are not square, they could hit the casing with serious risk

to the operator and others in the vicinity.

Note: The planing surface will end up rough and uneven unless the blades are set and secured

properly.

The examples below show proper and improper settings:

• Correct setting - clean smooth cut (Fig. III).

• Nicks in surface – as caused by the edge of one or all blades not being parallel to the

surface of the rear base (Fig. IV).

• Gouging at start – as caused by the edge of one or all blades not protruding enough in

relation to the surface of the rear base (Fig. V).

• Gouging at end – as caused by the edge of one or all blades protruding too far in relation

to the surface of the rear base (Fig. VI).

(a) Movable Front Base (11) which is altered by the Depth Adjustment Knob (12)

(b) Fixed Rear Base (6)

Drive belt replacement

1. Replace the drive belt by first taking out the three cross-head screws that secure the Drive

Belt Cover (8) on the left-hand side of the planer when viewed from the rear (Image N)

Note. The front screw is longer than the other two. Take care to replace this screw in the same

hole when replacing the cover.

2. Remove the damaged belt by pulling it sideways off the top pulley and turning the bottom

pulley by hand. Use a soft brush to clean the pulleys and the surrounding area

Note: Wear eye protection when cleaning out the pulley area.

3. With the six continuous ‘v’ profiles on the inside, place the new belt over the bottom

pulley. Half-fit the other end of the belt on the top pulley, then roll the belt in place whilst

turning the pulley

4. Check the belt runs evenly by manually turning the belt

5. Replace the Drive Belt Cover and the three fixing screws, ensuring the longer screw is

located in the hole at the front of the cover

6. Plug the machine back into the power outlet and switch the tool on and run for a minute to

make sure that the motor and belt are operating correctly

Brushes

• Over time the carbon brushes inside the motor may become worn

• Excessively worn brushes may cause loss of power, intermittent failure, or visible sparking

• If you suspect that the brushes may be worn, have them replaced at an authorised

service centre

Disposal

Always adhere to national regulations when disposing of power tools that are no longer

functional and are not viable for repair.

• Do not dispose of power tools, or other waste electrical and electronic equipment (WEEE),

with household waste

• Contact your local waste disposal authority for information on the correct way to dispose of

power tools

459500_Manual.indd 10 03/09/2019 09:21

Loading...

Loading...