Do not use excessive amounts of sealer. The extra sealer may become dislodged and

could block the oil passages in the crankcases causing severe engine damage.

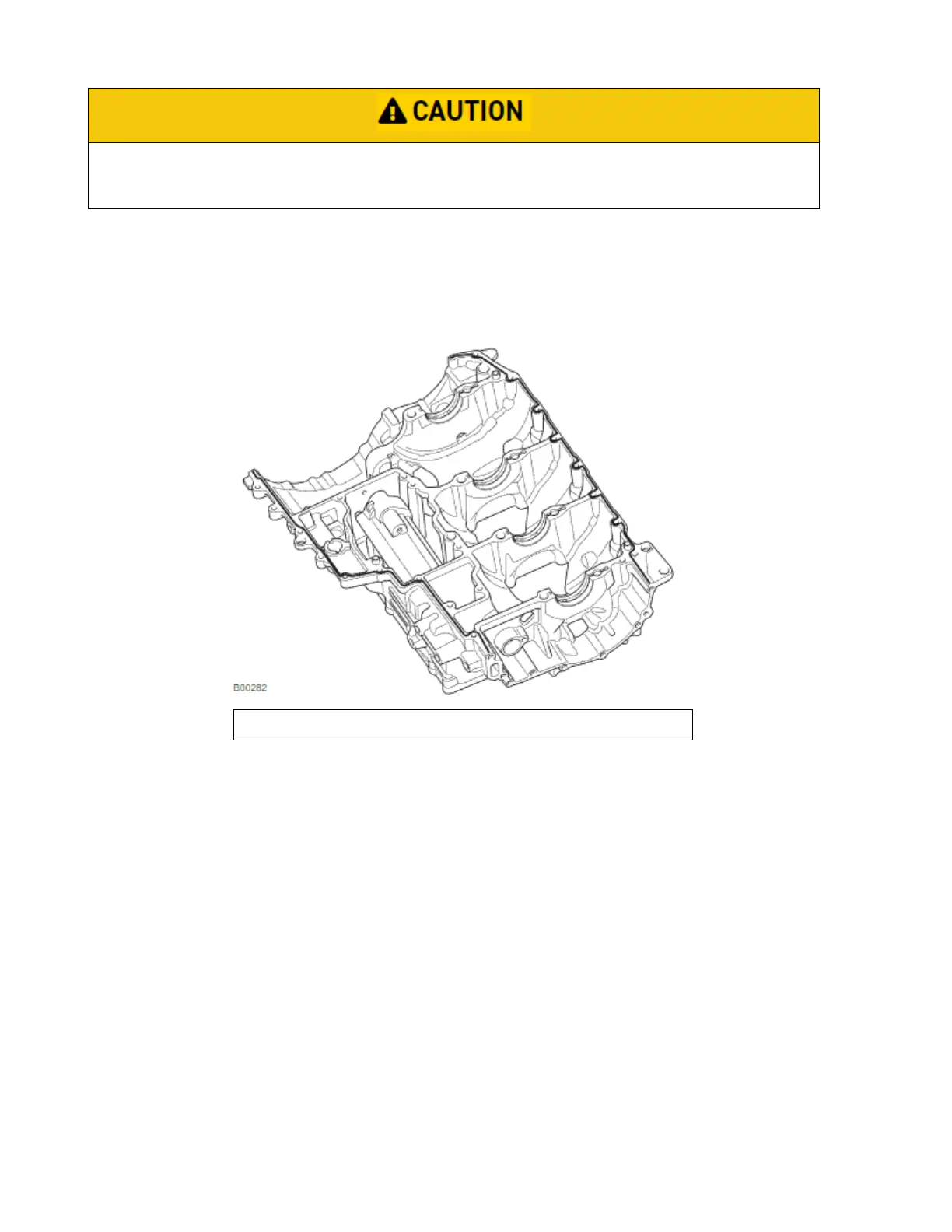

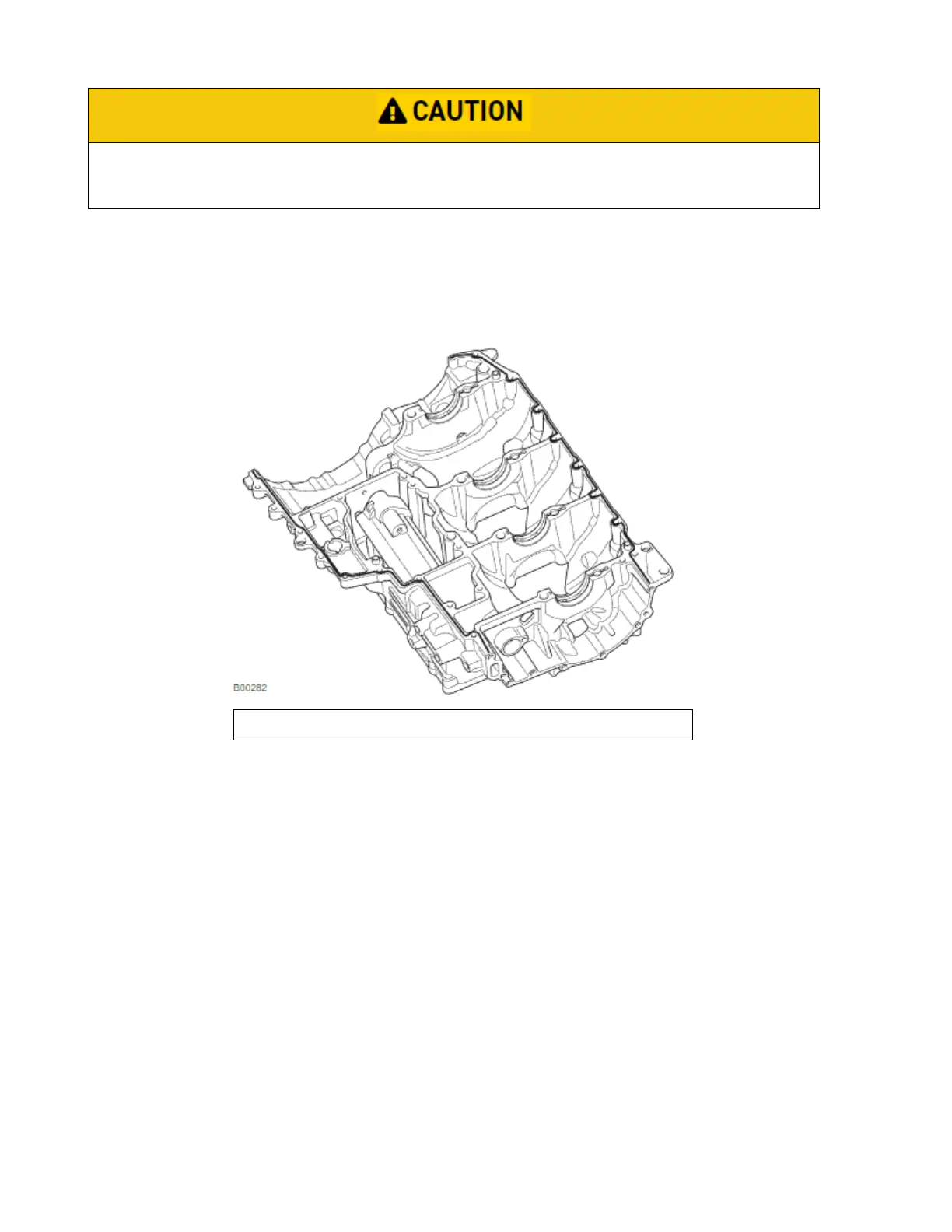

6. Apply a 2 mm diameter bead of silicone sealant (at the factory, ThreeBond 1216E is

used) to the lower crankcase mating faces. The sealant is to be 2.5 mm inside of the

external edges.

Sealer Areas

7. Install and lubricate the crankshaft bearing shells with a 50/50 solution of engine oil

and molybdenum disulphide grease.

8. Position the lower crankcase to the upper crankcase. An assistant may be required to

support the crankcase during alignment. Make sure the following:

• the gear change actuator shaft locates onto the gear change actuator knuckle

correctly.

• the two ends of the gear change return spring has its dowel in the lower

crankcase between them.

Loading...

Loading...