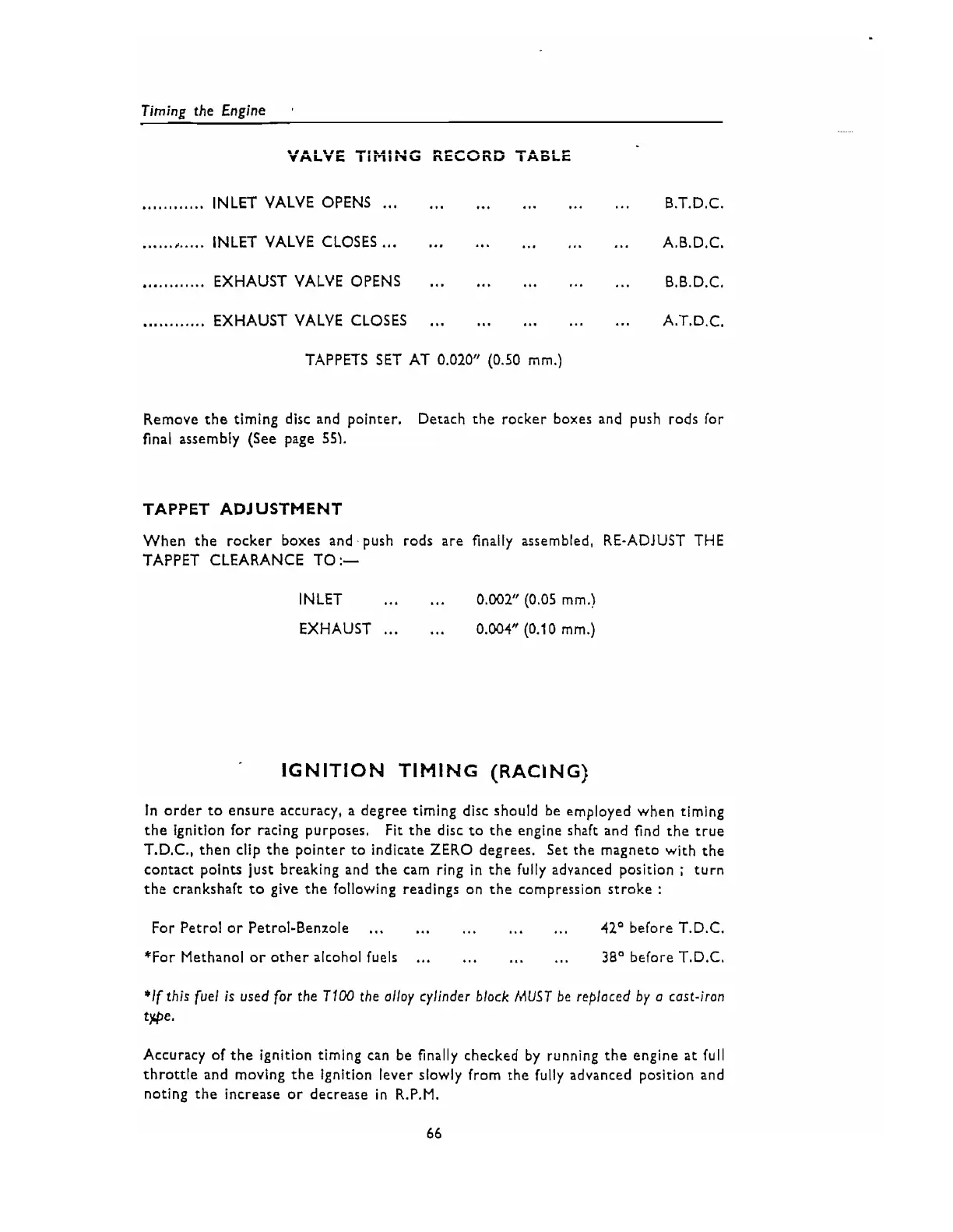

Timing the Engine

...

...

............

INLET VALVE OPENS

...

...

...

...

B.T.D.C.

...

...

......

,

.....

INLET VALVE CLOSES

...

...

...

...

A.B.D.C.

...

............

EXHAUST VALVE OPENS

...

...

...

...

B.B.D.C.

...

............

EXHAUST VALVE CLOSES

...

...

...

...

A.T.D.C.

TAPPETS SET AT 0.020" (0.50 mm.)

Remove the timing disc and pointer.

Detach the rocker boxes and push rods for

final assernbiy (See page

551.

TAPPET ADJUSTMENT

When the rocker boxes andpush rods are finally assembled, RE-ADJUST THE

TAPPET CLEARANCE TO

:-

INLET

...

...

0.002" (0.05 mrn.)

...

EXHAUST

...

0.004" (0.10 mrn.)

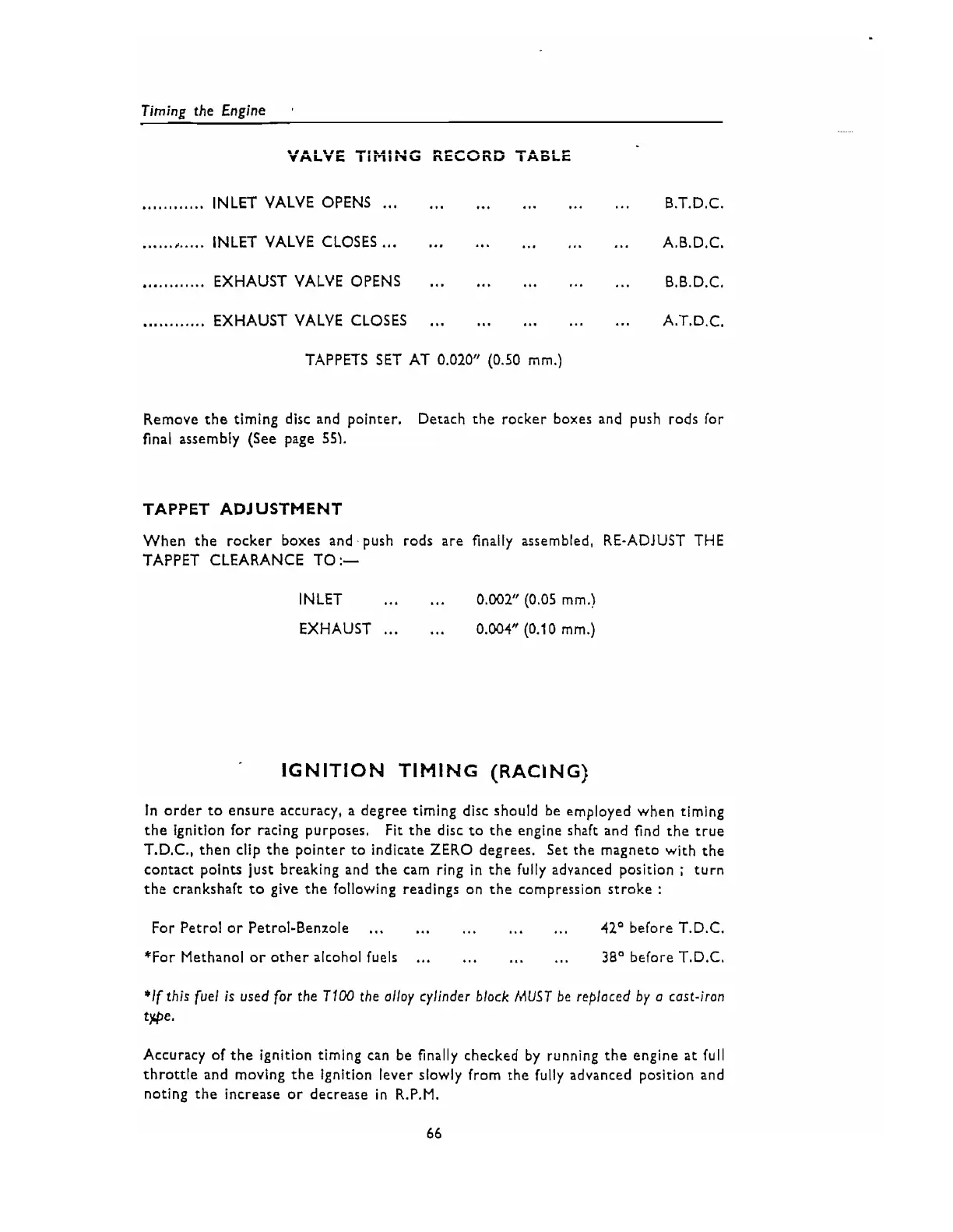

IGNITION TIMING (RACING)

In order to ensure accuracy, a degree timing disc should be employed when timing

the ignition for acing purposes. Fit the disc to the engine shaft and find the true

T.D.C., then clip the pointer to indicate ZERO degrees. Set the magneto with the

contact points just breaking and the cam ring in the fully advanced position

;

turn

the crankshaft to give the following readings on the compression stroke

:

...

For Petrol or Petrol-Benzole

...

...

...

...

42' before T.D.C.

*For Methanol or other alcohol fuels

...

...

...

...

36"

before T.D.C.

'If

this fuel is used for the

TIW

the alloy cylinder block

MUST

be replaced by o cost-iron

type.

Accuracy of the ignition timing can be finally checked by running the engine at full

throttle and moving the ignition lever slowly from the fully advanced position and

noting the increase or decrease in R.P.M.

Loading...

Loading...