CLUTCH

I.

GENERAL

DATA

47.LU\I:

TRAVELAVAILABLE

Model

A

6

G

9".

Hydraulically operated from

twin

bore

master cylinder which incorporates the

brake master cylinder.

Ball bearing release bearing.

Clearance between ball bearing release bear-

ing and release

levers-.0625".

TO

RELEASECLUTCH

Nine, 120-130 lb.

R ream

thrust springs.

IN

TU~S

DlRECrlON

Single dry plate with six springs.

All

six

springs cushion the driving torque, whilst

three (grey in colour) cushion the over

run.

Free travel on clutch pedal

=

.820.

CIearance between piston rod and master

!

cylinder piston

=

.030.

End float in Slave Cylinder fork assembly

=

.079".

Height of release lever tip from face of

flywheel

=

1.895".

Long portion of hub towards Gearbox.

2.

TOOL

DATA

Borg and Beck Gauge Plate No. CG.192.

Land Thickness

=

.33OV (see uage

13).

-

\

S"

Churchill ~ool S~acers

......

......

NO.

3

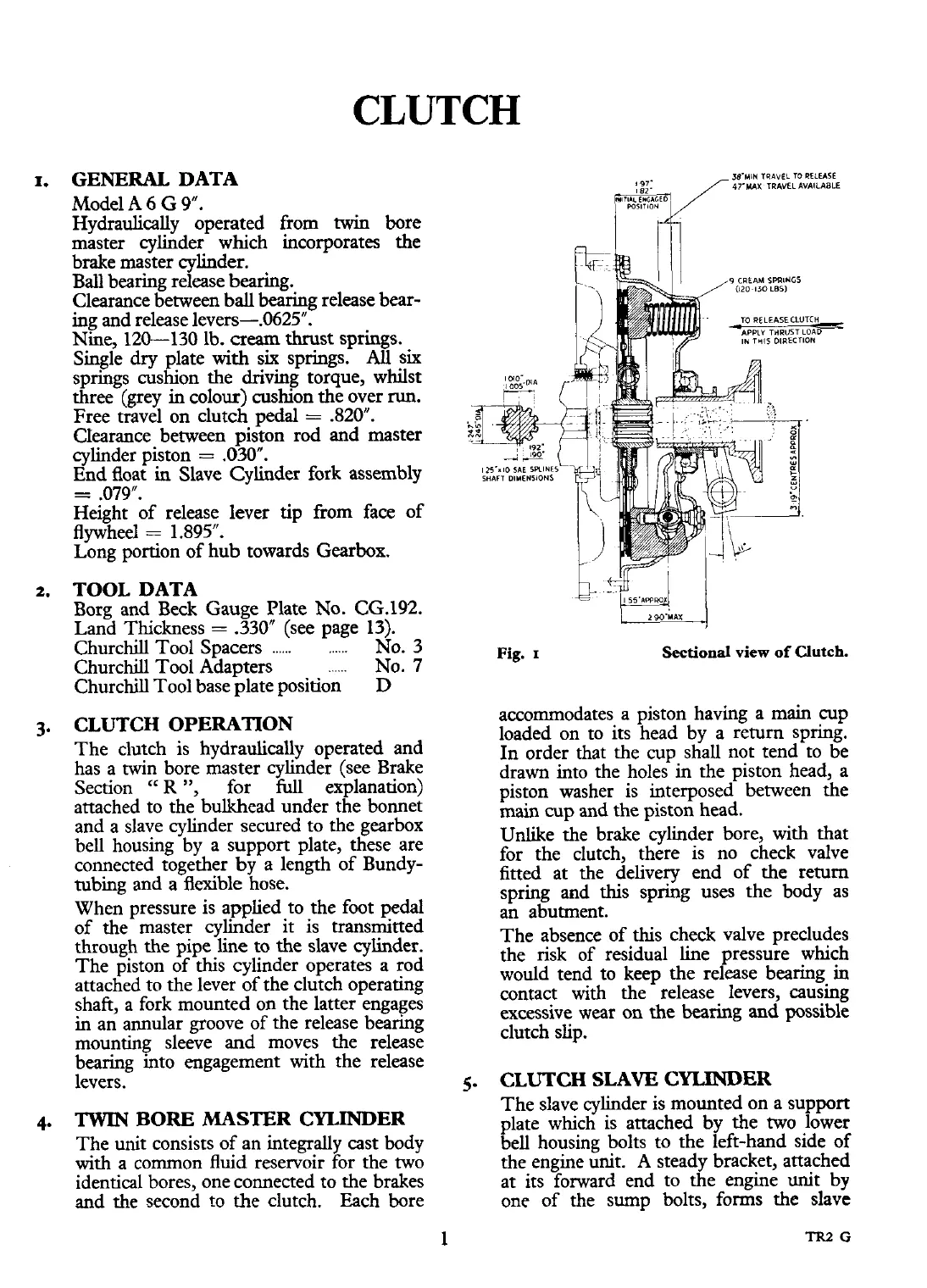

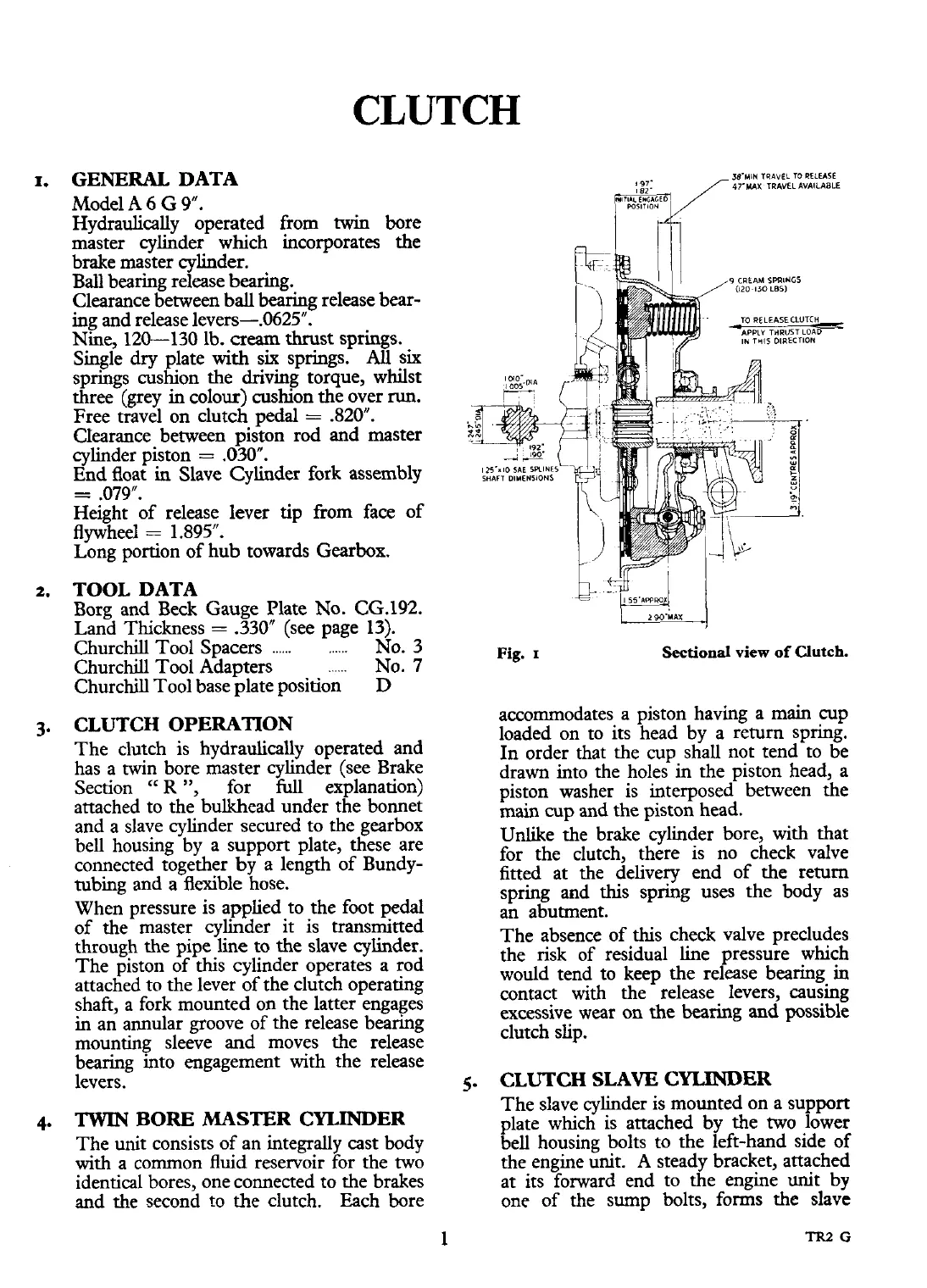

Fig.

I

Churchill Tool ~ha~ters

......

No.

7

Churchill Tool base plate position

D

Sectional

view

of

Clutch.

3.

CLUTCH OPERATION

accommodates a piston having a main cup

loaded on to its head by a return spring.

The clutch is hydraulically operated and

In order that the cup shall not tend to be

has a twin bore master cylinder (see Brake

drawn into the holes in the piston head, a

Section

"R

",

for

full

explanation) piston washer is interposed between the

attached to the bulkhead under the bonnet

main cup and the piston head.

and a slave cylinder secured to the gearbox

bell housing by a support plate, these are

Unlike the brake cylinder bore, with that

connected together

by

a length of Bundy-

for the clutch, there is no check valve

tubing and a flexible hose.

fitted at the delivery end of the return

spring and this spring uses the body as

When pressure is applied to the foot pedal

an abutment.

of the master cylinder it is transmitted

through the pipe line to the slave cylinder.

The absence of this check valve precludes

The piston of this cylinder operates a rod

the risk of residual line pressure which

attached to the lever of the clutch operating

would tend to keep the release bearing

in

contact with the release levers, causing

shaft, a fork mounted on the latter engages

in

an annular groove

of

the release bearing

excessive wear on the bearing and possible

mounting sleeve

and

moves the release

clutch slip.

bearing &to engagement with the release

levers.

5.

CLUTCH SLAVE

CYLINDER

The slave cylinder is mounted on a support

4.

TWIN

BORE

MASTER

CYLINDER

plate which is attached by the two lower

The unit consists of an integrally cast body

bell housing bolts to the left-hand side of

with a common

fluid

reservoir for the two

the engine unit.

A

steady bracket, attached

identical bores, one connected to the brakes

at its forward end to the engine unit by

and the second to the clutch. Each bore

one of the sump bolts, forms the slave

Loading...

Loading...