CLUTCH

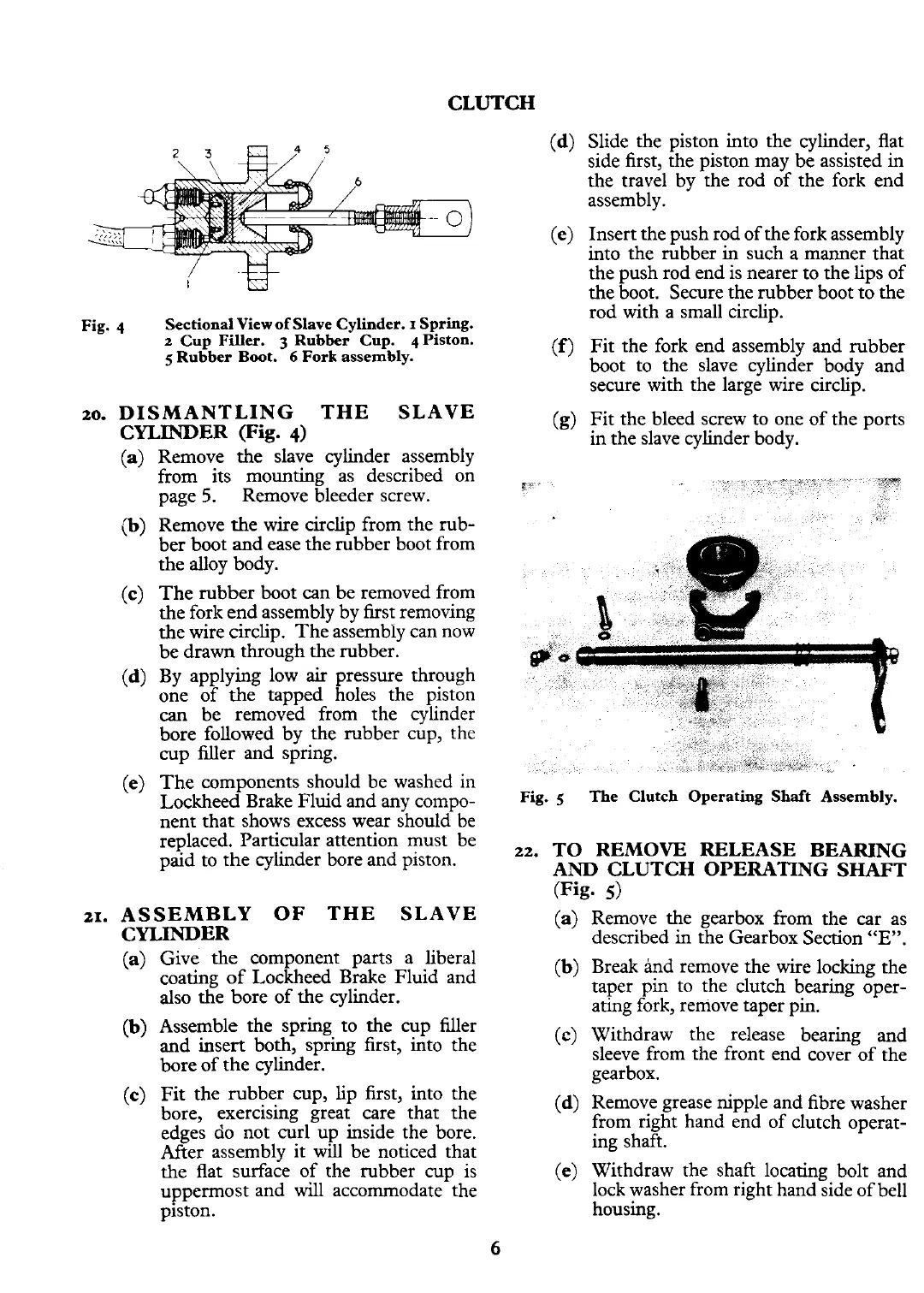

Fig.

4

Sectional View of Slave Cylinder.

I

Spring.

2

Cup Filler.

3

Rubber Cup.

4

Piston.

S

Rubber Boot.

6

Fork assembly.

20.

DISMANTLING THE SLAVE

CYLINDER

(Fig.

4)

(a)

Remove the slave cylinder assembly

from its mounting as described on

page

5.

Remove bleeder screw.

(b)

Remove the wire circlip from the rub-

ber boot and ease the rubber boot from

the alloy body.

(c)

The rubber boot can be removed from

the fork end assembly by first removing

the wire circlip. The assembly can now

be drawn through the rubber.

(d)

By applying low

air

pressure through

one of the tapped holes the piston

can

be removed from the cylinder

bore followed by the rubber cup, the

cup filler and spring.

(e)

The components should be washed in

Lockheed Brake Fluid and any compo-

nent that shows excess wear should be

replaced. Particular attention must be

paid to the cylinder bore and piston.

21.

ASSEMBLY OF THE SLAVE

CYLINDER

(a)

Give the component parts

a

liberal

coating of Lockheed Brake Fluid and

also the bore of the cylinder.

(b)

Assemble the spring to the cup filler

and insert both, spring first, into the

bore of the cylinder.

(c)

Fit the rubber cup, lip first, into the

bore, exercising great care that the

edges do not curl up inside the bore.

After assembly it

will

be noticed that

the flat surface of the rubber cup is

uppermost and

will

accommodate the

piston.

(d)

Slide the piston into the cylinder, flat

side first, the piston may be assisted in

the travel by the rod of the fork end

assembly.

(e)

Insert the push rod of the fork assembly

into the rubber in such a manner that

the push rod end is nearer to the lips of

the boot. Secure the rubber boot to the

rod with a small circlip.

(f)

Fit the fork end assembly and rubber

boot to the slave cylinder body and

secure with the large wire circlip.

(g)

Fit the bleed screw to one of the ports

in the slave cylinder body.

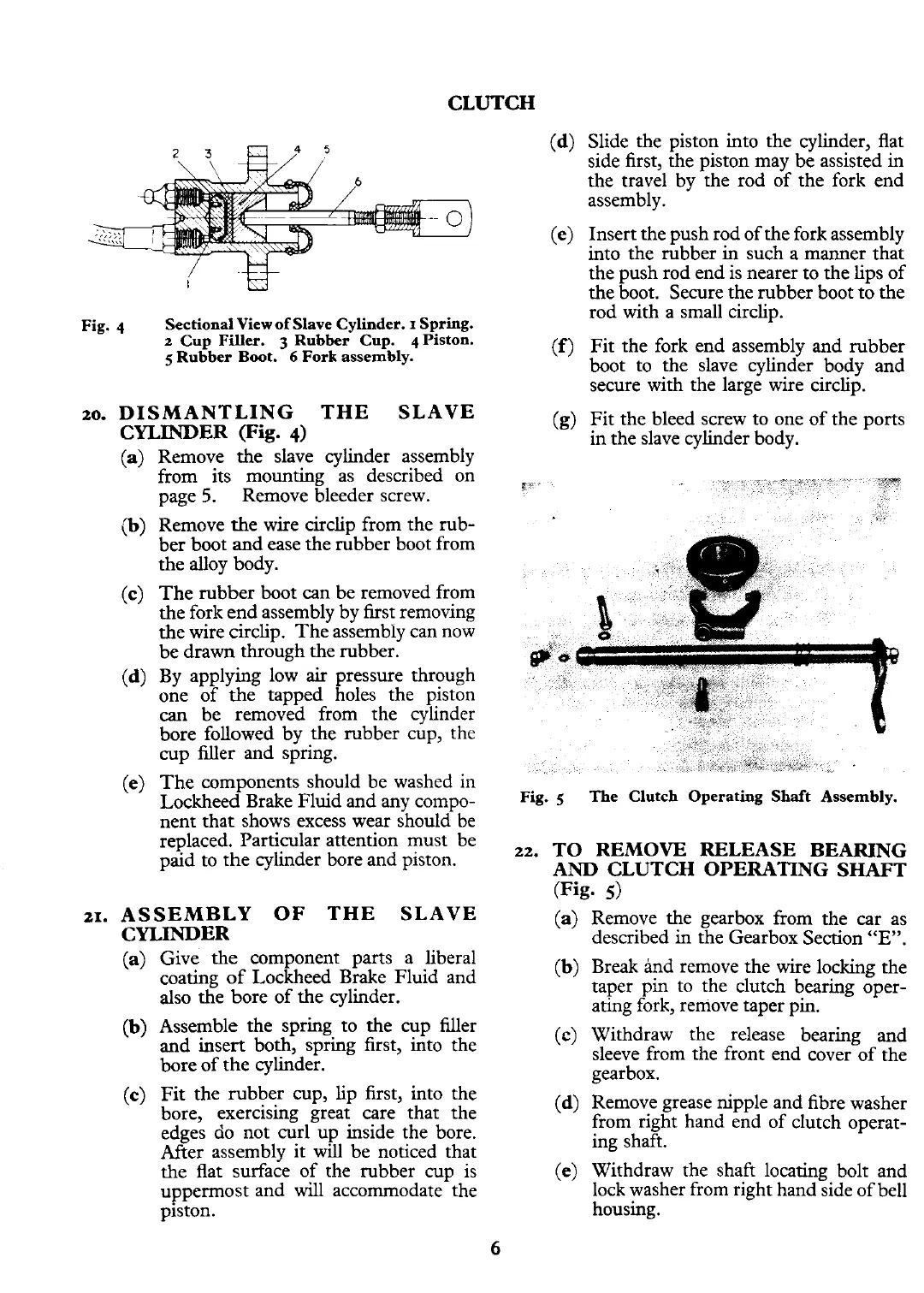

Fig.

5

The

Clutch Operating Shaft Assembly.

22.

TO REMOVE RELEASE BEARING

AND CLUTCH OPERATING SHAFT

(Fig.

5)

(a)

Remove the gearbox from the car as

described in the Gearbox Section

"E".

(b)

Break and remove the wire locking the

taper pin to the clutch bearing oper-

ating fork, remove taper pin.

(c)

Withdraw the release bearing and

sleeve from the front end cover of the

gearbox.

(d)

Remove grease nipple and fibre washer

from right hand end of clutch operat-

ing shaft.

(e)

Withdraw the shaft locating bolt and

lock washer from right hand side of bell

housing.

Loading...

Loading...