CLUTCH

(f)

Holding the clutch operating fork

with-

draw the shaft from the left.

(g) Remove spring and grease nipple with

fibre washer from lever end of shaft.

NOTE-To effect the removal of the shaft

from cars prior to Commission No.

TS.

41

1, there is no necessity to remove

the grease nipple (operation d) and the

shaft locating bolt (operation

e)

is sit-

uated on the left hand side of the bell

housing.

23.

TO REPLACE CLUTCH OPERATING

SHAFT AND RELEASE BEARING

The replacement of the clutch operating

shaft and release bearing is the reversal of

the removal. It will be found, however, that

light pressure will be necessary to compress

the spring on the operating shaft to insert

and tighten the shaft locating bolt.

When fitting the ball bearing release bearing,

locate the pegs of the operating fork in the

groove of the bearing. Secure the operating

fork to the shaft with the taper pin and lock

'the head with wire.

24.

REMOVAL OF

THE

CLUTCH

FROM FLYWHEEL WITH GEAR-

BOX REMOVED

(a) Slacken the six holding bolts, in the

outer rirnof the cover pressing, a turn at

a time by diagonal selection until the

thrust spring pressure is relieved.

(b) Remove the six bolts and lift away the

cover assembly and driven plate assem-

bly from the two locating dowels.

(c)

Inspect the two dowels in the flywheel

for looseness and burrs and replace if

necessary.

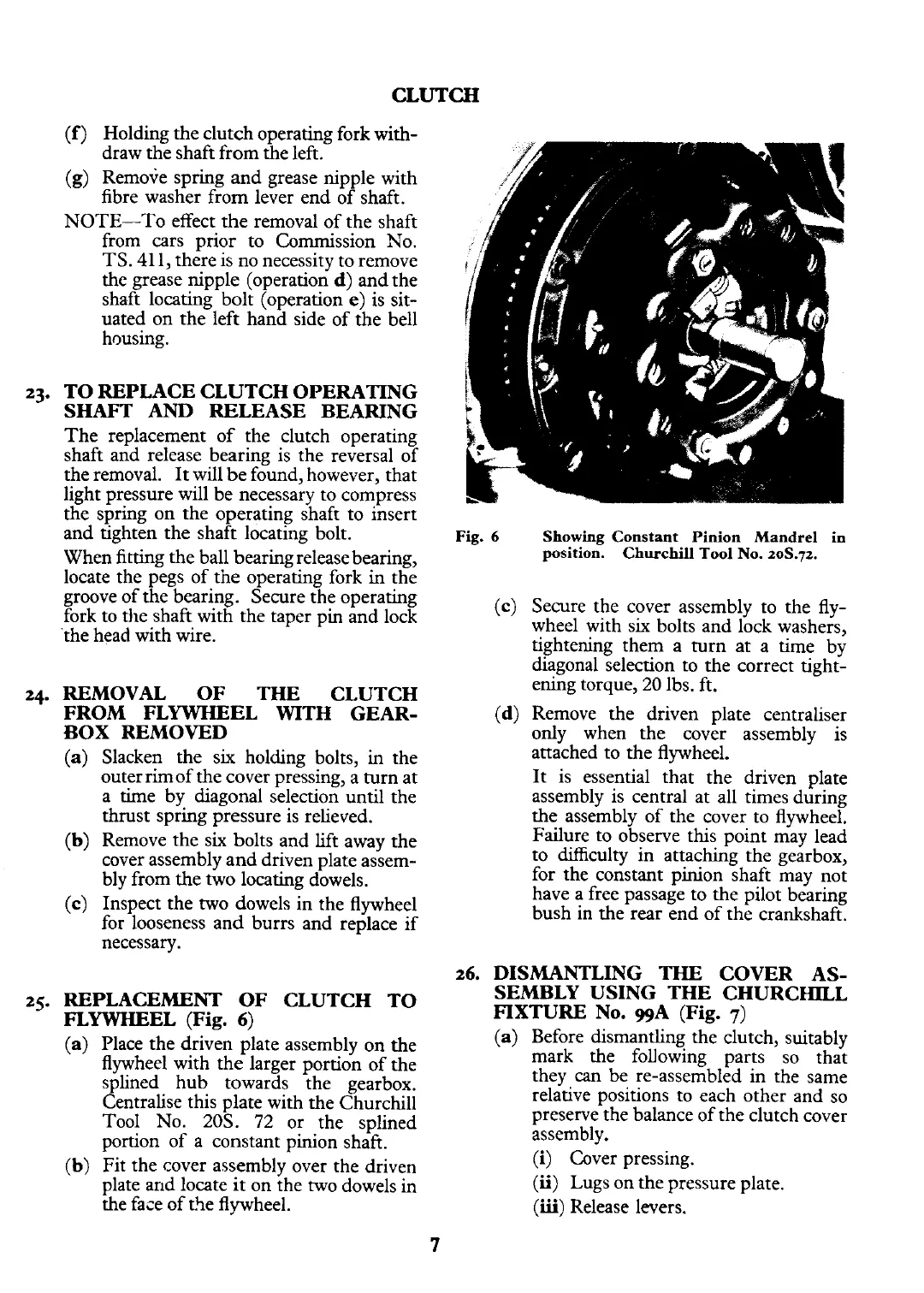

25.

REPLACEMENT OF CLUTCH TO

FLYWHEEL

(Fig. 6)

(a) Place the driven plate assembly on the

flywheel with the larger portion of the

splined hub towards the gearbox.

Centralise this plate with the Churchill

Tool No.

20s.

72

or the splined

portion of a constant pinion shaft.

(b) Fit the cover assembly over the driven

plate and locate it on the two dowels in

the face of the flywheel.

Fig.

6

Showing Constant Pinion Mandrel in

position. Churchill Tool No. 2oS.72.

(c) Secure the cover assembly to the fly-

wheel with six bolts and lock washers,

tightening them a turn at a time by

diagonal selection to the correct tight-

ening torque,

20 lbs. ft.

(d) Remove the driven plate centraliser

only when the cover assembly is

attached to the flywheel.

It is essential that the driven plate

assembly is central at all times during

the assembly of the cover to flywheel.

Failure to observe this point may lead

to difficulty in attaching the gearbox,

for the constant pinion shaft may not

have a free passage to the pilot bearing

bush in the rear end of the crankshaft.

26.

DISMANTLING

THE

COVER AS-

SEMBLY USING THE CHURCHILL

FIXTURE No.

ggA

(Fig.

7)

(a) Before dismantling the clutch, suitably

mark the following parts so that

they

can

be re-assembled in the same

relative positions to each other and so

preserve the balance of the clutch cover

assembly.

(i) Cover pressing.

(ii)

Lugs on the pressure plate.

(iii)

Release levers.

Loading...

Loading...