CLUTCH

end of the strut push outwards to the

periphery of the pressure plate.

Offer

up the lever assembly,first engaging the

eye bolt shank within the hole in the

pressure plate, then locate the

strut in

the groove of the release lever. Fit the

remaining levers

in

a similar manner.

(b) Place the pressure plate on the wooden

blocks on the base of the press and posi-

tion the thrust springs on the bosses on

the pressure plate.

(c) Place the cover pressing, with the

anti-

rattle springs fitted, over the pressure

plate ensuring that the lugs protrude

through the cover slots.

(d) Arrange a wooden block across the

cover and apply pressure to compress

the whole assembly. Screw the adjust-

ing nuts on to the eye bolts sufficiently

so that pressure can be released.

30.

INSPECTION

OF

COVER

ASSEMBLY

Before re-assembling the clutch

unit

the

parts should be cleaned and inspected. Any

components which show considerable wear

on its working surface should be replaced.

The thrust springs and anti-rattle springs

should be checked against new ones of the

correct strength, and any found to be

obviously weak should be replaced.

The

anti-rattle springs should be assembled to

the cover pressing. The working face of the

cast iron pressure plate should also be

inspected and if the ground face is deeply

scored or grooved it should be either re-

ground or replaced by a new plate.

If any parts are changed or a new pressure

plate fitted, it is essential it should be

static-

ally balanced.

71.

AD.JUSTING

THE

RELEASE LEVERS

-

In service, the original adjustments made by

the clutch manufacturer,

will

require no

attention and re-adjustment is only neces-

sary

if

the cover assembly has been

dis-

mantled.

There are three methods bv which the

release levers may be adjusted.'

(i)

Churchill No. 99A Clutch Fixture.

(ii)

Borg and Beck No. CG 192 gauge

plate. (If available).

(iii)

In the absence of the above the

DrivenPlate Assembly may beused.

(a) Churchill No. ggA Clutch

Fixture.

Both this Company and the Clutch

manufacturers recommend this method.

Details can be found on page 9.

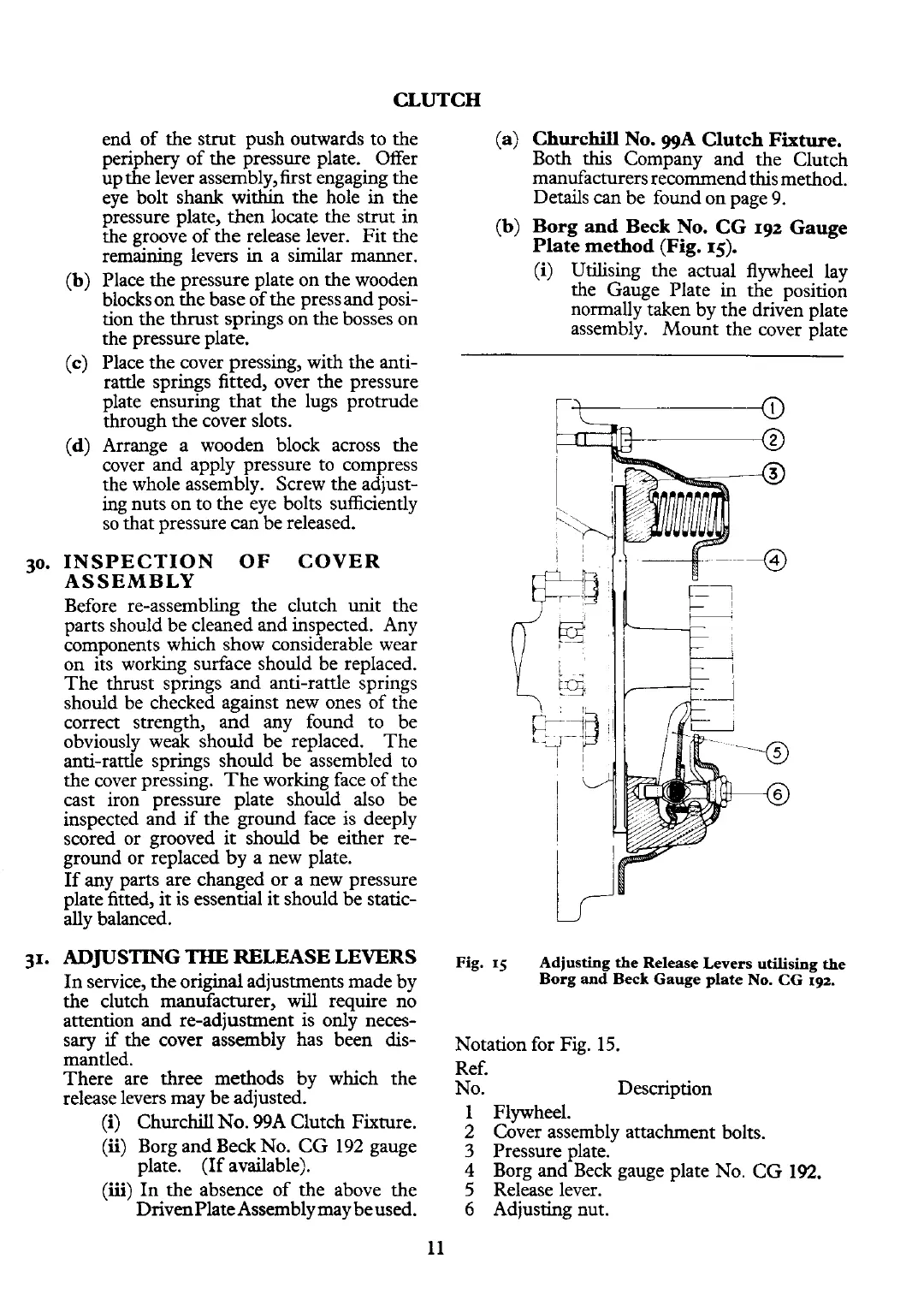

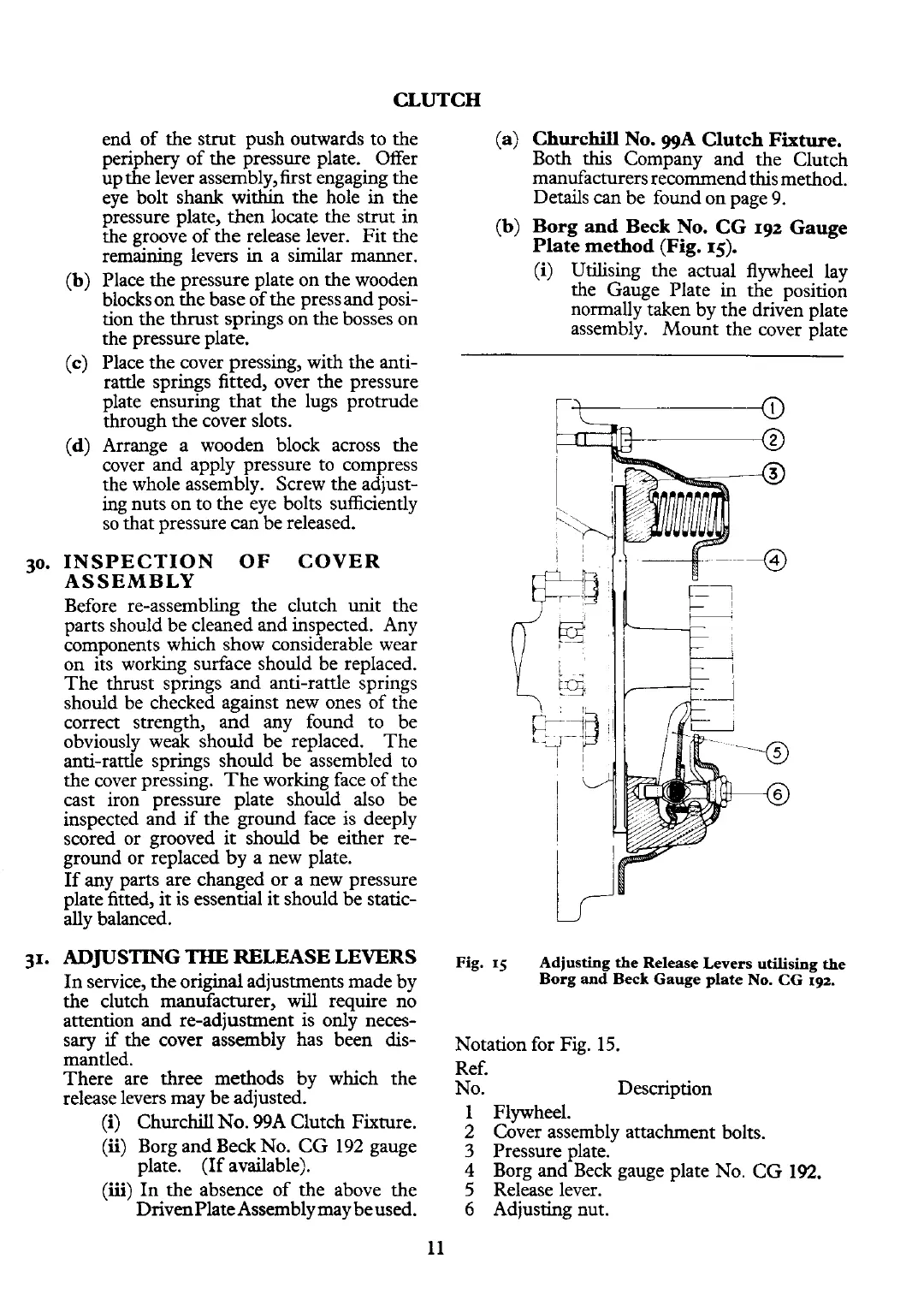

(b) Borg and Beck No. CG

192

Gauge

Plate method (Fig.

15).

(i)

Utilising the actual flywheel lay

the Gauge Plate in the position

normally taken by the driven plate

assembly. Mount the cover plate

Fig.

15

Adjusting the Release Levers utilising the

Borg and

Beck

Gauge plate No. CG

192.

Notation for Fig. 15.

Ref.

No. Description

1 Flywheel.

2 Cover assembly attachment bolts.

3

Pressure plate.

4

Borg and Beck gauge plate No. CG

192.

5

Release lever.

6

Adjusting nut.

Loading...

Loading...