CLUTCH

(1)

Secure pillar firmly into centre of base

plate. Place on No.

7

adapter, recessed

side downward, followed by gauge

finger.

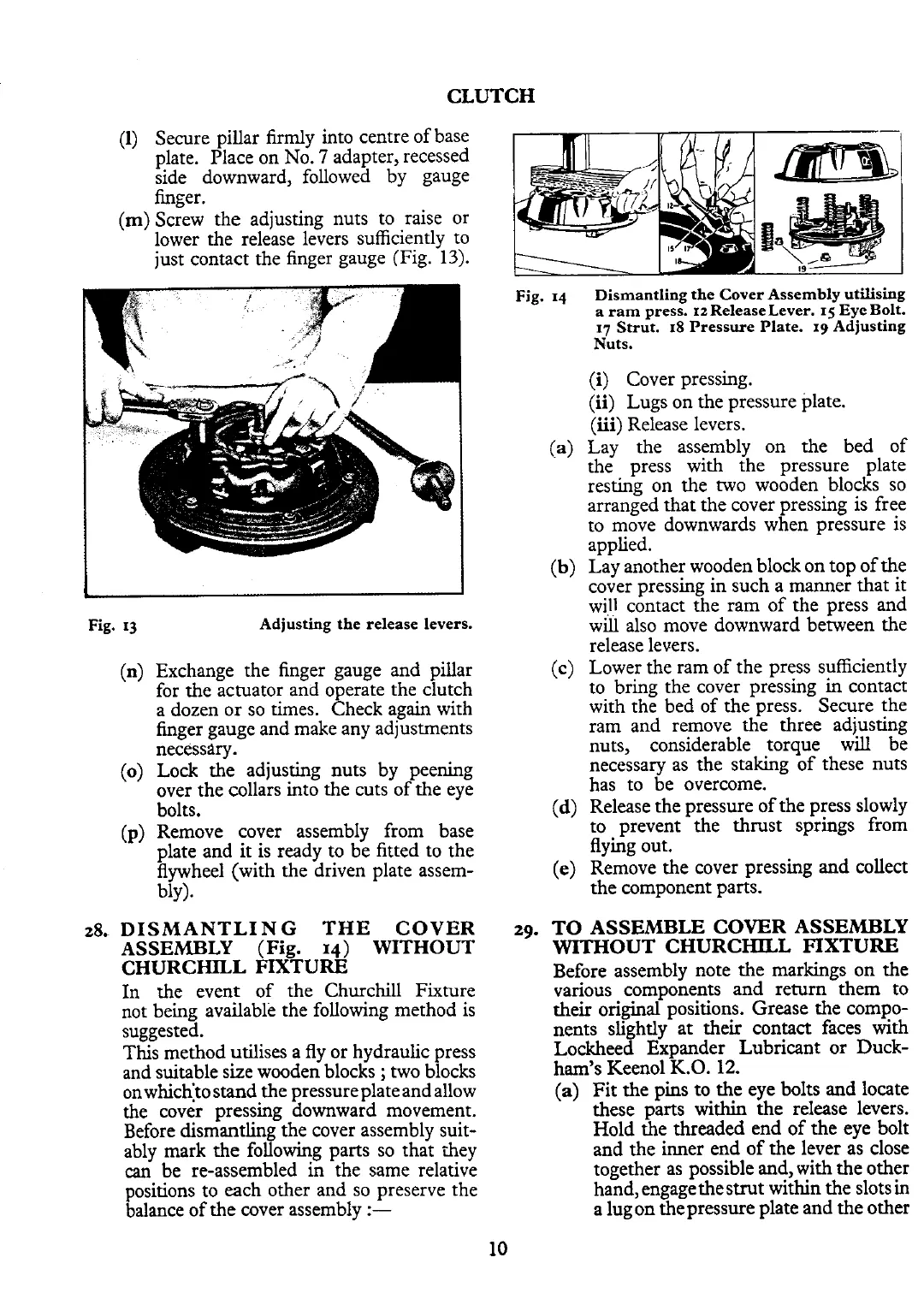

(m)

Screw the adjusting nuts to raise or

lower the release levers sufficiently to

just contact the finger gauge (Fig. 13).

Fig.

13

Adjusting the release levers.

(n)

Exchange the finger gauge and pillar

for the actuator and operate the clutch

a dozen or so times. Check again with

finger gauge and make any adjustments

necessary.

(0)

Lock the adjusting nuts by peening

over the collars into the cuts of the eye

bolts.

(p)

Remove cover assembly from base

plate and it is ready to be fitted to the

flywheel (with the driven plate assem-

bly).

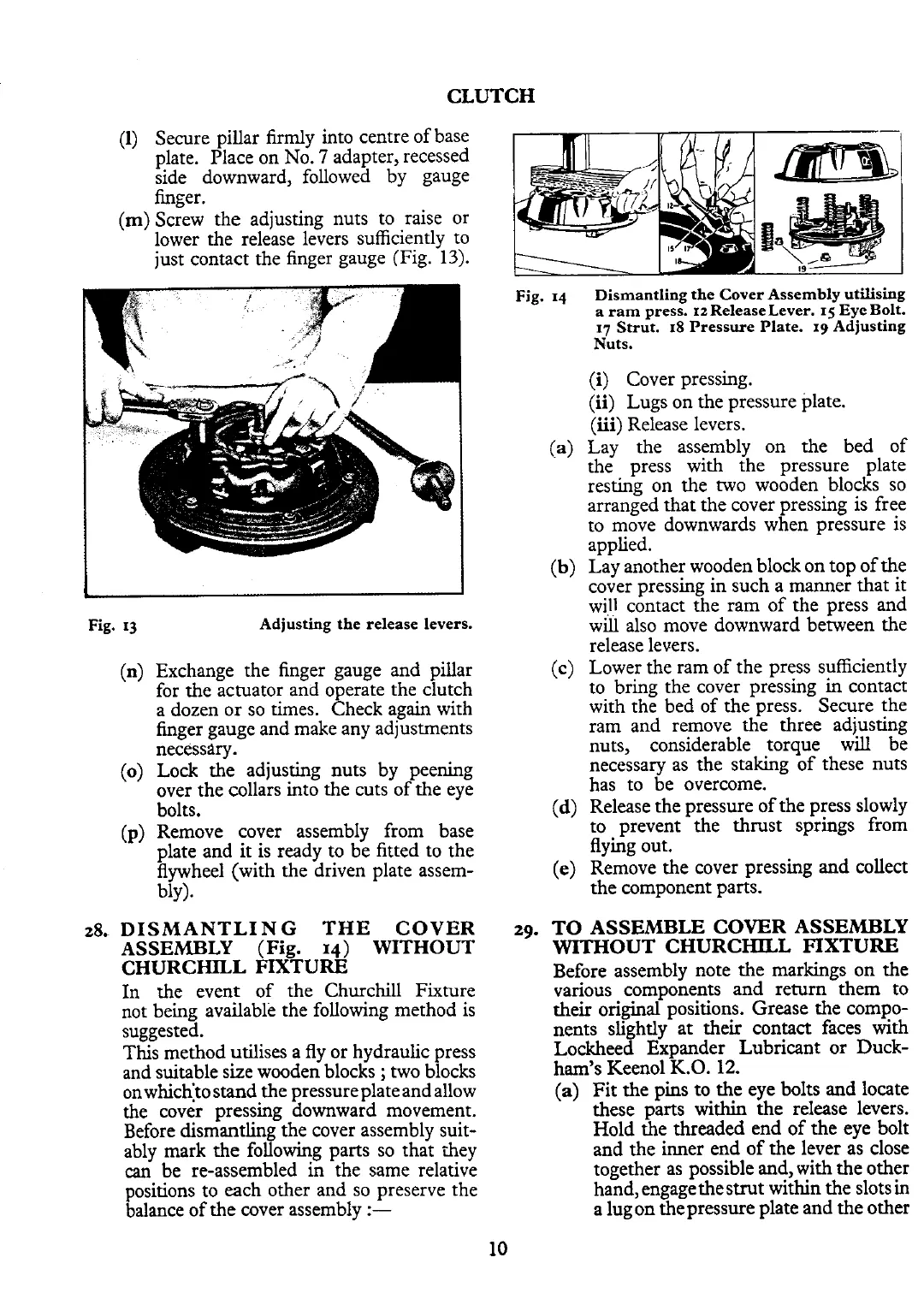

28.

DISMANTLING THE COVER

ASSEMBLY

(Fig.

14)

WITHOUT

CHURCHILL FIXTURE

In

the event of the Churchill Fixture

not being available the following method is

suggested.

This method utilises a fly or hydraulic press

and suitable size wooden blocks

;

two blocks

onwhich:to stand the pressure plate and allow

the cover pressing downward movement.

Before dismantling the cover assembly suit-

ably mark the following parts so that they

can

be re-assembled in the same relative

positions to each other and so preserve the

balance of the cover assembly

:-

Fig.

14

Dismantling the Cover Assembly utilising

a

ram Dress.

12

ReleaseLever.

I<

Eve Bolt.

--

-

---

I,

~trti

18 Pressure Plate. xgd~djusting

Nuts.

(i)

Cover pressing.

(ii) Lugs on the pressure plate.

(iii) Release levers.

(a)

Lay the assembly on the bed of

the press with the pressure plate

resting on the two wooden blocks so

arranged that the cover pressing is free

to move downwards when pressure is

applied.

(b)

Lay another wooden block on top of the

cover pressing in such a manner that it

will contact the ram of the press and

will also move downward between the

release levers.

(c)

Lower the ram of the press sufficiently

to bring the cover pressing in contact

with the bed of the press. Secure the

ram and remove the three adjusting

nuts, considerable torque will be

necessary as the staking of these nuts

has to be overcome.

(d)

Release the pressure of the press slowly

to prevent the thrust springs from

flying out.

(e) Remove the cover pressing and collect

the component parts.

29.

TO ASSEMBLE COVER ASSEMBLY

WITHOUT CHURCHILL FIXTURE

Before assembly note the markings on the

various components and return them to

their original positions. Grease the compo-

nents slightly at their contact faces with

Lockheed Expander Lubricant or Duck-

ham's Keen01

K.O.

12.

(a)

Fit the pins to the eye bolts and locate

these parts

within

the release levers.

Hold the threaded end of the eye bolt

and the inner end of the lever as close

together as possible and, with the other

hand, engage

thestrut within the slots

in

a lug on the pressure plate and the other

Loading...

Loading...