CLUTCH

(j) Lift up inner end of release lever and

disengage the strut. Repeat procedure

for 2nd and 3rd levers.

(k) Gripping the tip of the release lever and

the eye bolt lift out the assembly from

the pressure plate. Repeat procedure

for 2nd and 3rd levers.

(1)

Remove the eye bolts from release

levers and take out pins. Remove the

struts from pressure plate.

27.

ASSEMBLY OF COVER PLATE

ASSEMBLY USING THE

CHURCHILL FIXTURE

No.

ggA

Before assembling a smear of Lockeed

Ex-

pander Lubricant or Duckham's Keen01

K.O.

12 should be applied to the release

lever pins, contact faces of the struts, eye-

bolt seats in the cover pressing, drive lug

sides on the pressure plate and the plain end

of the eye bolts.

Assembly is to be made with strict regard to

the markings on certain parts and so ensure

that the unit remains in balance.

(a) Place strut in position in lug of pressure

plate.

~

(b)

Assemble pin to eye bolt and feed

threaded portion through release lever.

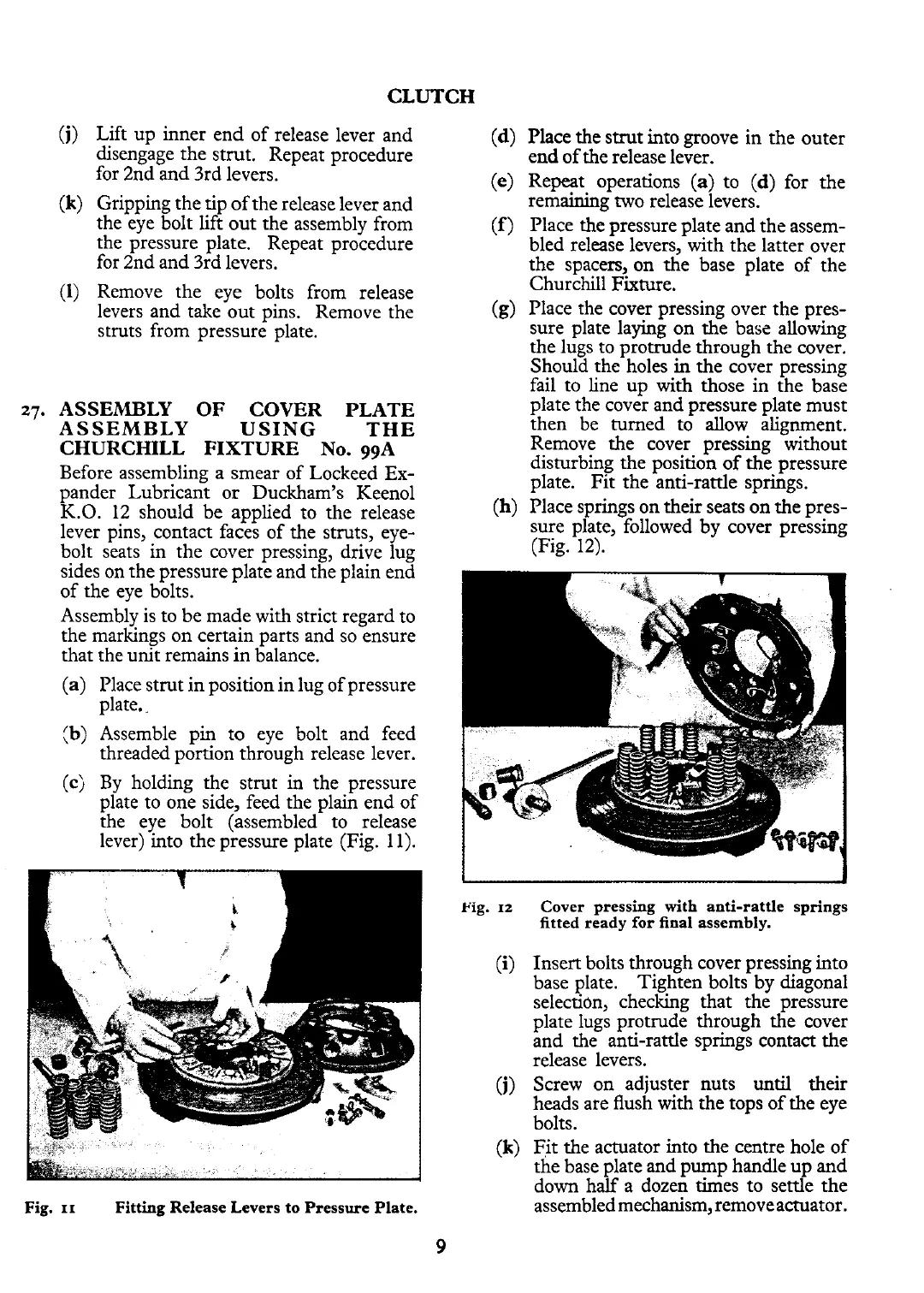

(C)

By holding the strut in the pressure

plate to one side, feed the plain end of

the eye bolt (assembled to release

lever) into the pressure plate (Fig. 11).

Fig.

11

Fitting Release Levers to Pressure Plate.

(d)

Place the strut into groove in the outer

end of the release lever.

(e)

Repeat operations (a) to

(d)

for the

remaining two release levers.

(f)

Place the pressure plate and the assem-

bled release levers, with the latter over

the spacers, on the base plate of the

Churchill Fixture.

(g)

Place the cover pressing over the pres-

sure plate laying on the base allowing

the lugs to protrude through the cover.

Should the holes

in

the cover pressing

fail to line up with those in the base

plate the cover and pressure plate must

then be turned to allow alignment.

Remove the cover pressing without

disturbing the position of the pressure

plate. Fit the anti-rattle springs.

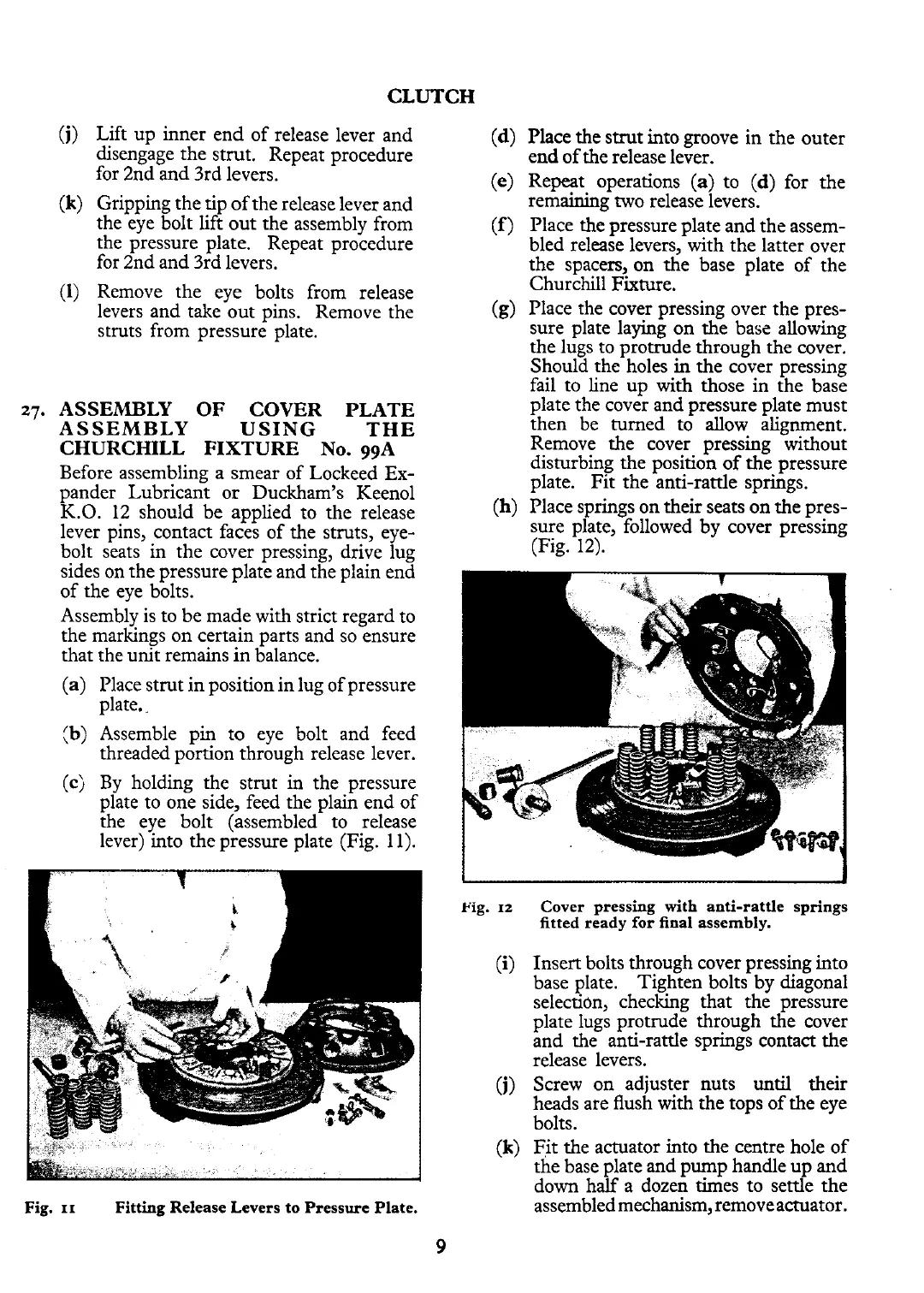

(h)

Place springs on their seats on the pres-

sure plate, followed by cover pressing

(Fig. 12).

Fig.

12

(9

Cover pressing with anti-rattle springs

fitted ready for final assembly.

Insert bolts through cover pressing into

base plate. Tighten bolts by diagonal

selection, checking that the pressure

plate lugs protrude through the cover

and the anti-rattle springs contact the

release levers.

Screw on adjuster nuts

until

their

heads are flush with the tops of the eye

bolts.

Fit the actuator into the centre hole of

the base plate and pump handle up and

down half a dozen times to settle the

assembled mechanism, remove actuator.

Loading...

Loading...