GEARBOX

(h)

Disconnect the two wires from their

terminals on the solenoid

if

an Over-

drive is fitted.

(i)

Remove gearbox mounting &er the

withdrawal of two nuts by jacking up

the

unit,using a block of wood between

jack and sump to avoid damage.

(j)

Remove starter motor bolts and slide

starter motor forwards clear of the bell

housing.

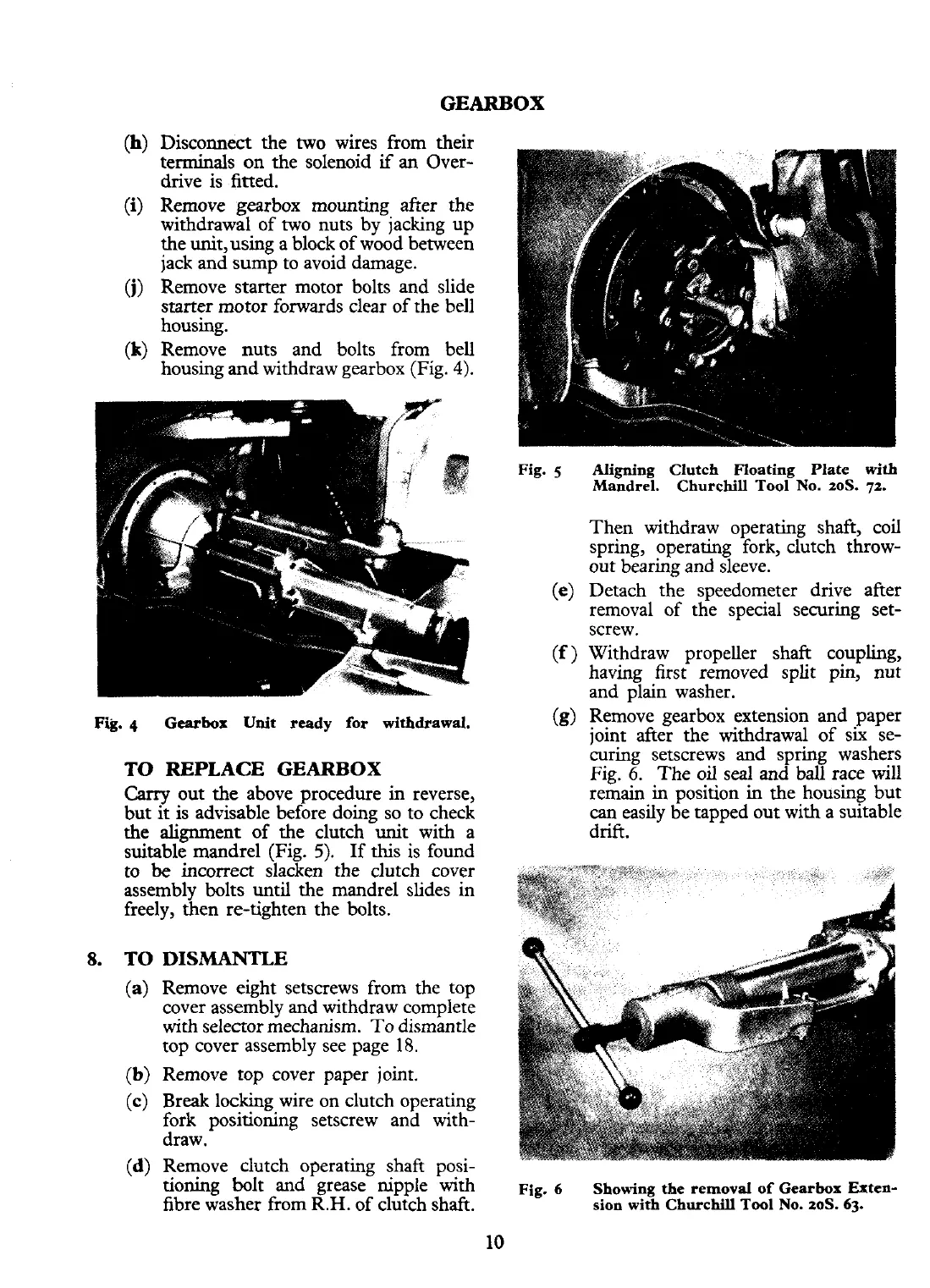

(k)

Remove nuts and bolts from bell

housing and withdraw gearbox (Fig.

4).

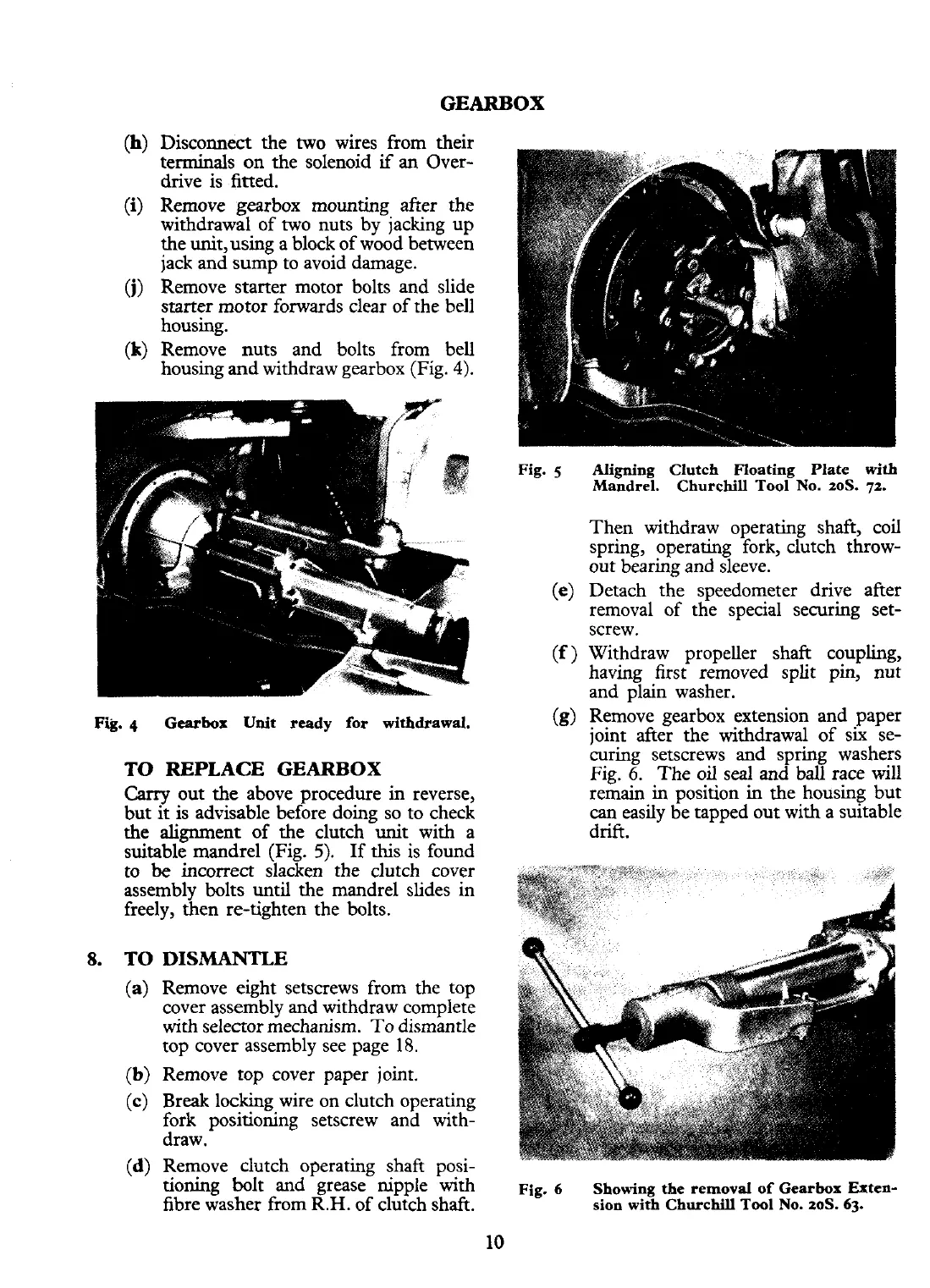

Fig.

5

Aligning Clutch Floating Plate with

Mandrel. Churchill Tool No. toS.

72.

Then withdraw operating shaft, coil

spring, operating fork, clutch throw-

out bearing and sleeve.

(e)

Detach the speedometer drive after

removal of the special securing set-

screw.

(f

)

Withdraw propeller shaft coupling,

having first removed split pin, nut

and plain washer.

Fig.

4

Gearbox

Unit

ready for withdrawal.

TO REPLACE GEARBOX

Carry

out the above procedure in reverse,

but

it

is advisable before doing so to check

the alignment of the clutch unit with a

suitable mandrel (Fig.

5).

If this is found

to

be

incorrect slacken the clutch cover

assembly bolts

until

the mandrel slides in

freely, then re-tighten the bolts.

TO

DISMANTLE

(a)

Remove eight setscrews from the top

cover assembly and withdraw complete

with

selector mechanism. To dismantle

top cover assembly see page 18.

(b)

Remove top cover paper joint.

(c)

Break

locking wire on clutch operating

fork positioning setscrew and with-

draw.

(d)

Remove clutch operating shaft posi-

(g)

Remove gearbox extension and paper

joint after the withdrawal of six se-

&ring setscrews and spring washers

Fie.

6.

The oil seal and

ball

race will

re&ain in position in the housing but

can

easily be tapped out with a suitable

drift.

tioning bolt and -grease- nipple -with

Fig.

6

Showing

the

removal of Gearbox Exten-

fibre washer from

R.H.

of clutch shaft.

sion

with

Churchill Tool No.

20s.

63.

Loading...

Loading...