GEARBOX

this position with the corrrct thrust

washer fitted, the small seeger circlip

fits properly into its recess. When

passing this circlip along the ground

portion of the constant pinion shaft,

take care not to score the shaft as such

damage may cause subsequent leakage

of oil. Fit larger

drclip into the amdar

groove

in

the outer ring of the ball

race.

(k)

Fit Oilite spigot bush into constant

pinion, placing the internally bevelled

portion of it towards the mainshaft.

(1)

Drive the constant pinion shaft and

bearing into the gearbox casing, posi-

tioning the gap in the circlip on the

outer ring of the bearing in

line

with

the oil hole

in

the casing.

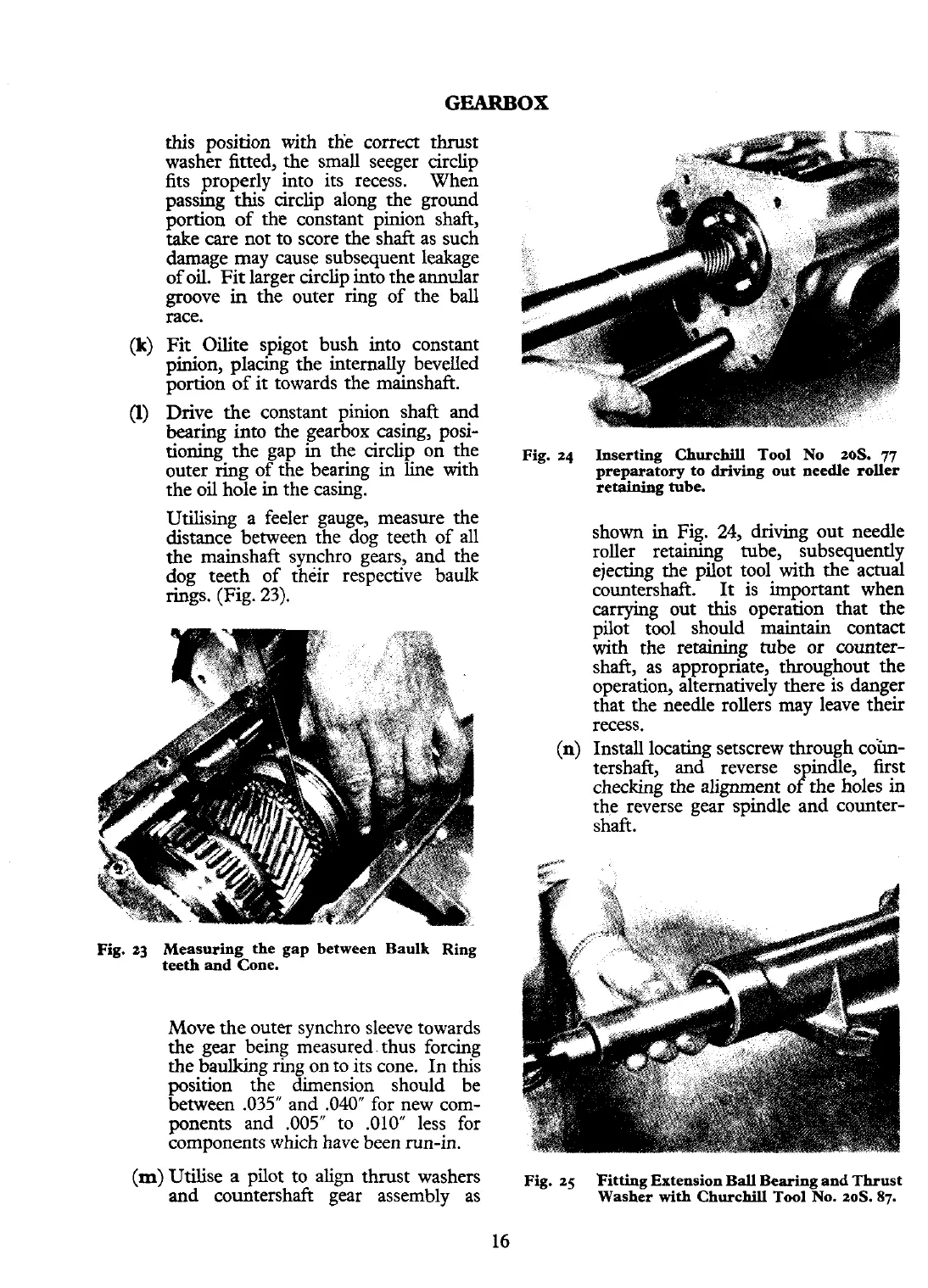

Utilising a feeler gauge, measure the

distance between the dog teeth of all

the mainshaft synchro gears, and the

dog teeth of their respective baulk

rings. (Fig. 23).

Fig. 23 Measuring the gap between Baulk Ring

teeth

and

Cone.

Move the outer synchro sleeve towards

the gear being measured. thus forcing

the

baulking ring on to its cone. In this

position the dimension should be

between

.035"

and

.040n

for new com-

ponents and

.005"

to

.010"

less for

components which have been run-in.

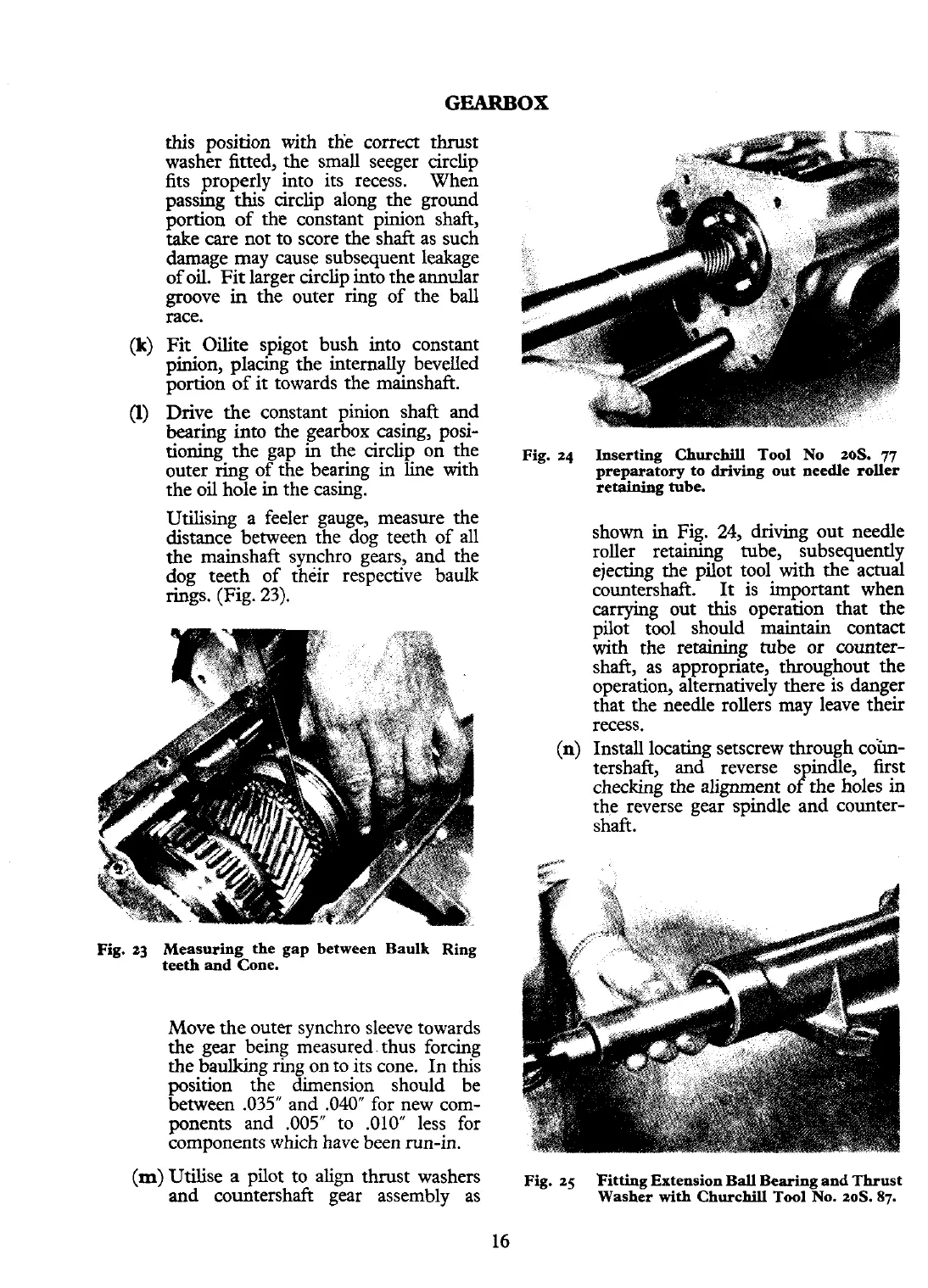

Fig.

24

Inserting

Churchill

Tool No 20s.

77

preparatory to driving out needle roller

retaining tube.

shown in Fig. 24, driving out needle

roller retaining tube, subsequently

ejecting the pilot tool

with

the actual

countershaft. It is important when

carrying out this operation that the

pilot tool should

maintain

contact

with the retaining tube or counter-

shaft, as appropriate, throughout the

operation, alternatively there is danger

that the needle rollers may leave their

recess.

(n)

Install locating setscrew through cob

tershaft, and reverse spindle, first

checking the alignment of the holes in

the reverse gear spindle and counter-

shaft.

(m)

Utilise a pilot to align thrust washers

Fig. 25

Fitting Extension Ball Bearing and Thrust

and countershaft gear assembly as

Washer

with

Churchill

Tool

NO.

20s.

87.

16

Loading...

Loading...