GEARBOX

(iv)

Axial

release loading of 2nd speed

synchro unit 25-27 lbs.

(v)

Axial

release loading of 3rd and

top speed synchro unit 19-21

lbs.

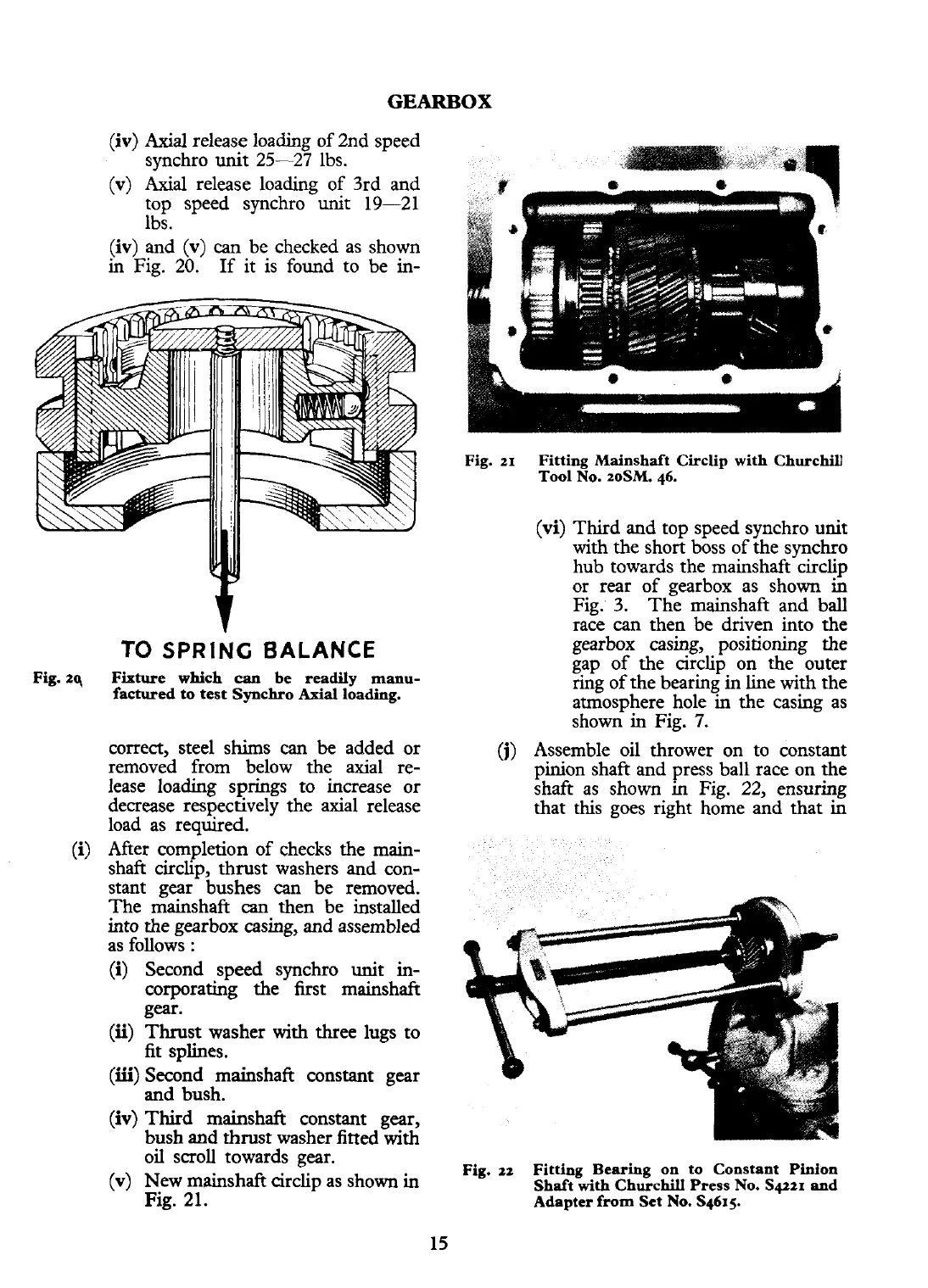

(iv)

and

(v)

can be checked as shown

in Fig. 20. If it is found to be in-

Fig.

2q

(9

TO

SPRING

BALANCE

Fixture which

can

be

readily

manu-

factured to test Synchro Axial loading.

correct, steel shims

can

be added or

removed from below the axial re-

lease loading springs to increase or

decrease respectively the axial release

load as required.

After completion of checks the

main-

shaft circlip, thrust washers and con-

stant gear bushes can be removed.

The mainshaft

can

then be installed

into the gearbox casing, and assembled

as follows

:

(i)

Second speed synchro unit in-

corporating the first mainshaft

gm.

(ii)

Thrust

washer

with

three lugs to

fit splines.

(iii)

Second mainshaft constant gear

and bush.

(iv)

Third mainshaft constant gear,

bush and thrust washer fitted

with

oil scroll towards gear.

(v)

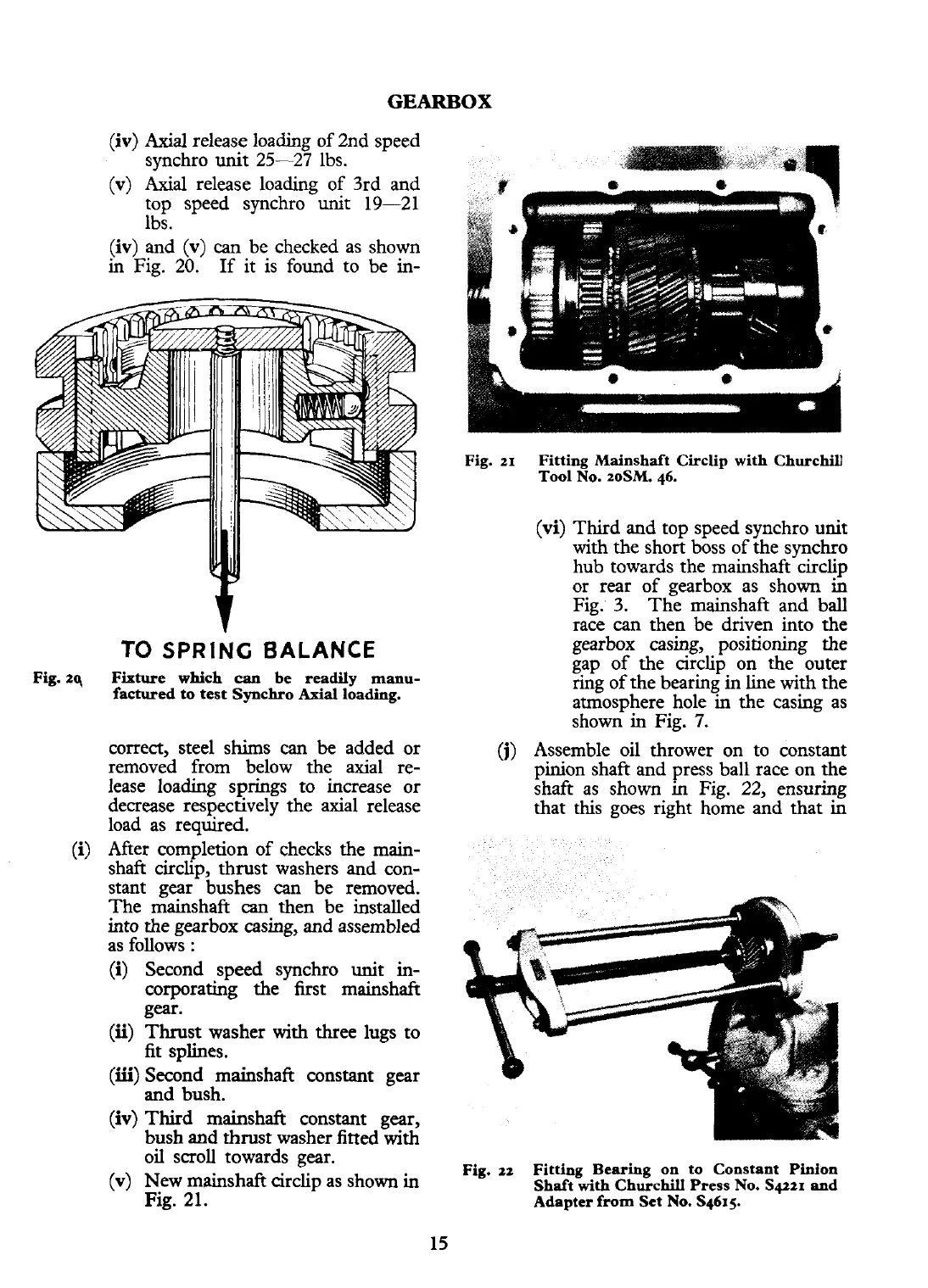

New mainshaft circlip as shown in

Fig. 21.

Fig.

21

Fitting Mainshaft Circlip with Churchill

Tool No. zoSM. 46.

(vi)

Third and top speed synchro unit

with the short boss of the synchro

hub towards the mainshaft circlip

or rear of gearbox as shown in

Fig. 3. The

mainshaft and ball

race can then be driven into the

gearbox casing, positioning the

gap of the circlip on the outer

ring of the bearing in line with the

atmosphere hole in the casing as

shown in Fig.

7.

(j)

Assemble oil thrower on to

constant

pinion shaft and press ball race on the

shaft as shown in Fig. 22, ensuring

that this goes right home and that in

Fig.

22

Fitting Bearing on to Constant Pinion

Shaft

with

Churchill Press No.

Sqtzr

and

Adapter

from

Set No. S4615

Loading...

Loading...