GEARBOX

(g)

(i) Install the triangular washer on

its splines on the mainshaft.

(g)

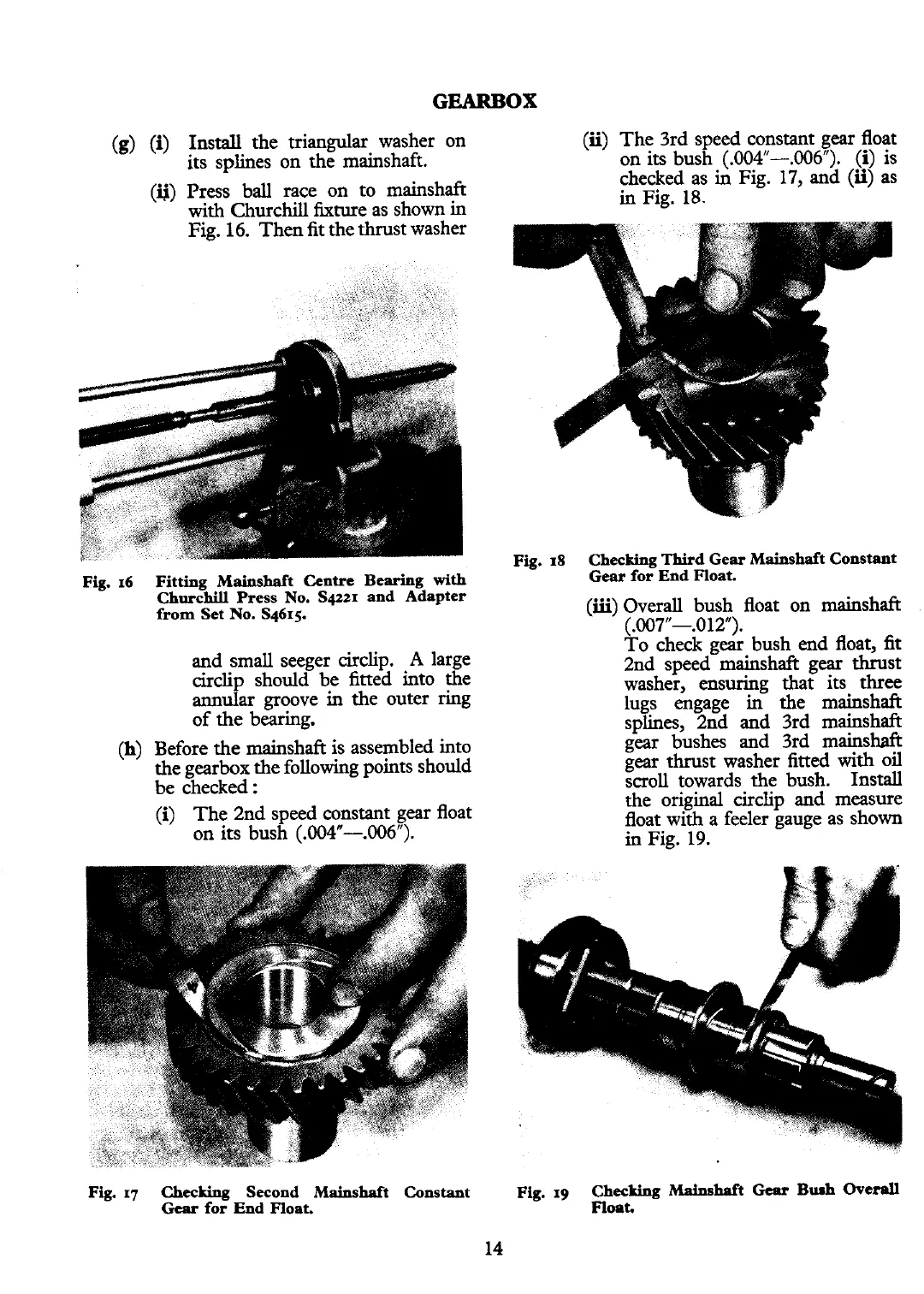

Press ball race on to mainshaft

with Churchill fixture as shown in

Fig.

16.

Then fit the thrust washer

Fig. 16

Fitting Mainshaft Centre Bearing

with

Churchill Press No. S4221 and Adapter

from Set No. S4615.

and small seeger &clip.

A

large

&clip should be fitted into the

annular groove

in

the outer ring

of the bearing.

(h)

Before the mainshaft is assembled into

the gearbox the following points should

be checked

:

(i)

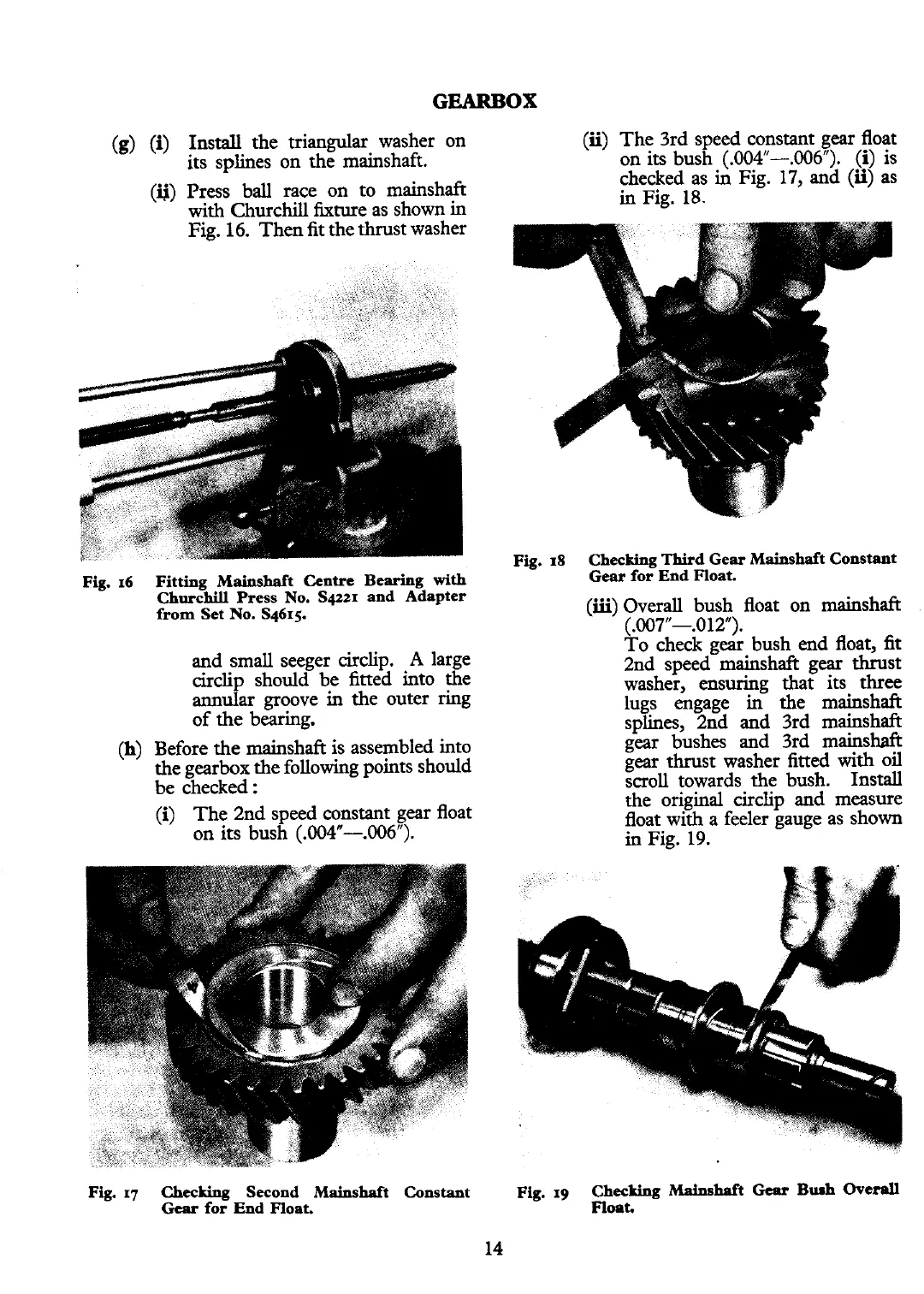

The 2nd speed constant gear float

on its bush (.004"-.006").

(ii)

The 3rd speed constant gear float

on its bush (.004-.006). (i) is

checked as in Fig. 17, and

(ii)

as

in Fig.

18.

Fig.

18

Checking Third Gear Mainshaft Constant

Gear for End Float.

(iii)

Overall bush float on mainshaft

(.007-.012").

To check gear bush end float, fit

2nd speed mainshaft gear thrust

washer, ensuring that its

three

lugs engage in the mainshaft

splines, 2nd and 3rd mainshaft

gear bushes and 3rd mainshaft

gear thrust washer fitted with oil

scroll towards the bush. Install

the original

circlip and measure

float with a feeler gauge as shown

in

Fig.

19.

Fig.

17

Checking Second Mainshaft Constant

Fig.

19 Checking

Mainshaft

Gear

Bush Overall

Gear

for End Float. Float.

14

Loading...

Loading...