GEARBOX

Fig.

14

Removing Mainshaft Centre Bearing with

Churchill

Press No.

S4221

and

adapter

from Set No.

S4615

(q)

Lift

out the reverse pinion (compound

gear) after tapping out its spindle

through the rear of the casing, the

retaining setscrew having been re-

moved in a previous operation (h).

(r)

The countershaft assembly

can

now-

be

Mied out of the casing

with

the needle

roller retaining tube still locating the

24 rollers at each end of the

counter-

shaft

in

their respective recesses. Lay

aside the two phosphor bronze thrust

washers for re-assembly.

(S)

The countershaft gears and distance

sleeve

can

now be removed from the

splined portion of the countershaft,

noting their position for re-assembly.

(t)

If it is desired to examine the needle

rollers they

can

be removed by with-

drawing the retaining tube. Note the

correct number of

48

for re-assembly

(24 at each end) and the needle roller

retaining rings can be tapped out with

a suitable drift.

9.

TO

ASSEMBLE

(a)

Thoroughly clean out the casing and

examine for cracks, ball race housings

for

wear

or other damage.

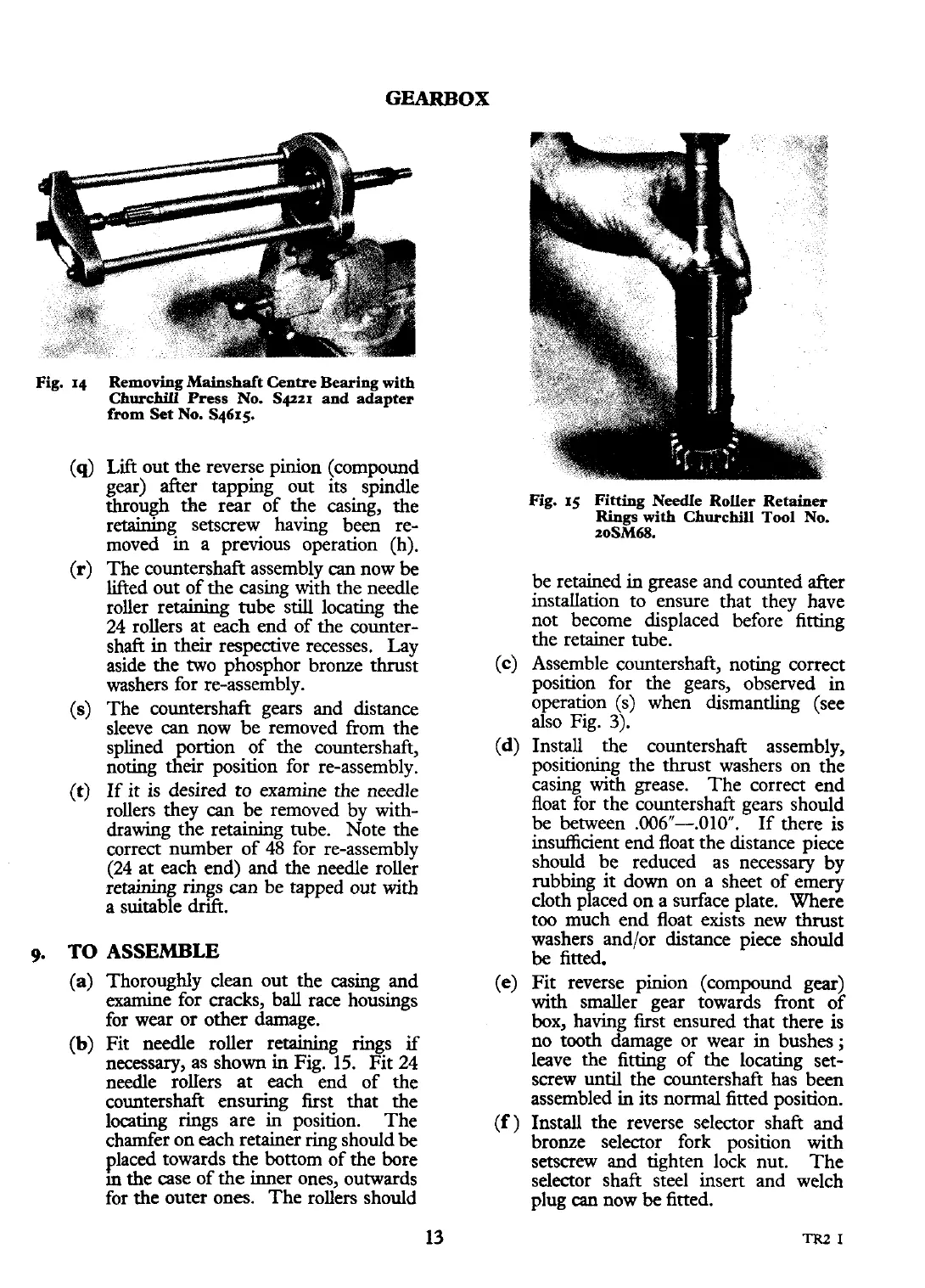

(b)

Fit needle roller retaining rings

if

necessary, as shown in Fig. 15. Fit 24

needle rollers at each end of the

countershaft ensuring first that the

locating rings are in position. The

chamfer on each retainer ring should be

placed towards the bottom of the bore

m

the case of the inner ones, outwards

for the outer ones. The rollers should

Fig.

15

Fitting

Needle Roller Retainer

Rings

with

Churchill

Tool No.

2oSM68.

be retained in grease and counted after

instauation to ensure that they have

not become displaced before fitting

the retainer tube.

(c)

Assemble countershaft, noting correct

position for the gears, observed in

operation

(S) when dismantling (see

also Fig.

3).

(d)

Install the countershaft assembly,

positioning the thrust washers on the

casing with grease. The correct end

float for the countershaft gears should

be between

.006"-.010".

If there is

insufficient end float the distance piece

should be reduced as necessary by

rubbing it down on a sheet of emery

cloth placed on a surface plate. Where

too much end float exists new

thrust

washers and/or distance piece should

be

fitted.

(e)

Fit reverse pinion (compound gear)

with

smaller gear towards front of

box, having first ensured that there is

no tooth damage or wear in bushes

;

leave the fitting of the locating set-

screw

until

the countershaft has been

assembled in its normal fitted position.

(f)

Install the reverse selector shaft and

bronze selector fork position with

setscrew and tighten lock nut. The

selector shaft steel insert and welch

plug

can

now

be

fitted.

Loading...

Loading...