GEARBOX

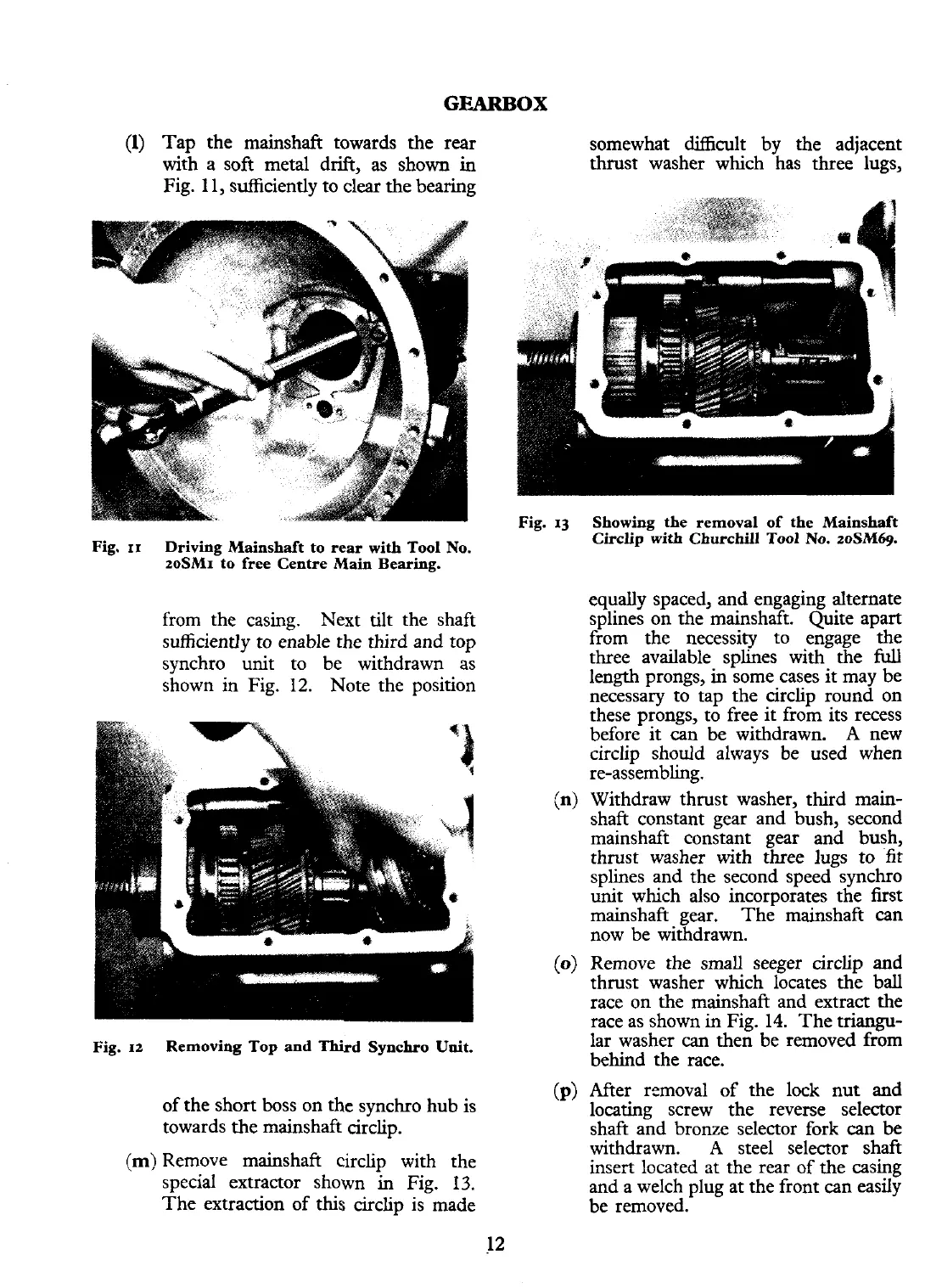

(1)

Tap the mainshaft towards the rear somewhat difficult by the adjacent

with a soft metal drift, as shown in

thrust washer which has

three

lugs,

Fig. 11, sufficiently to clear the bearing

Fig.

11

Driving Mainshaft to rear

with

Tool No.

Circlip

with

Churchill Tool No. 2oSM69.

~oSMI to free Centre Main Bearing.

equally spaced, and engaging alternate

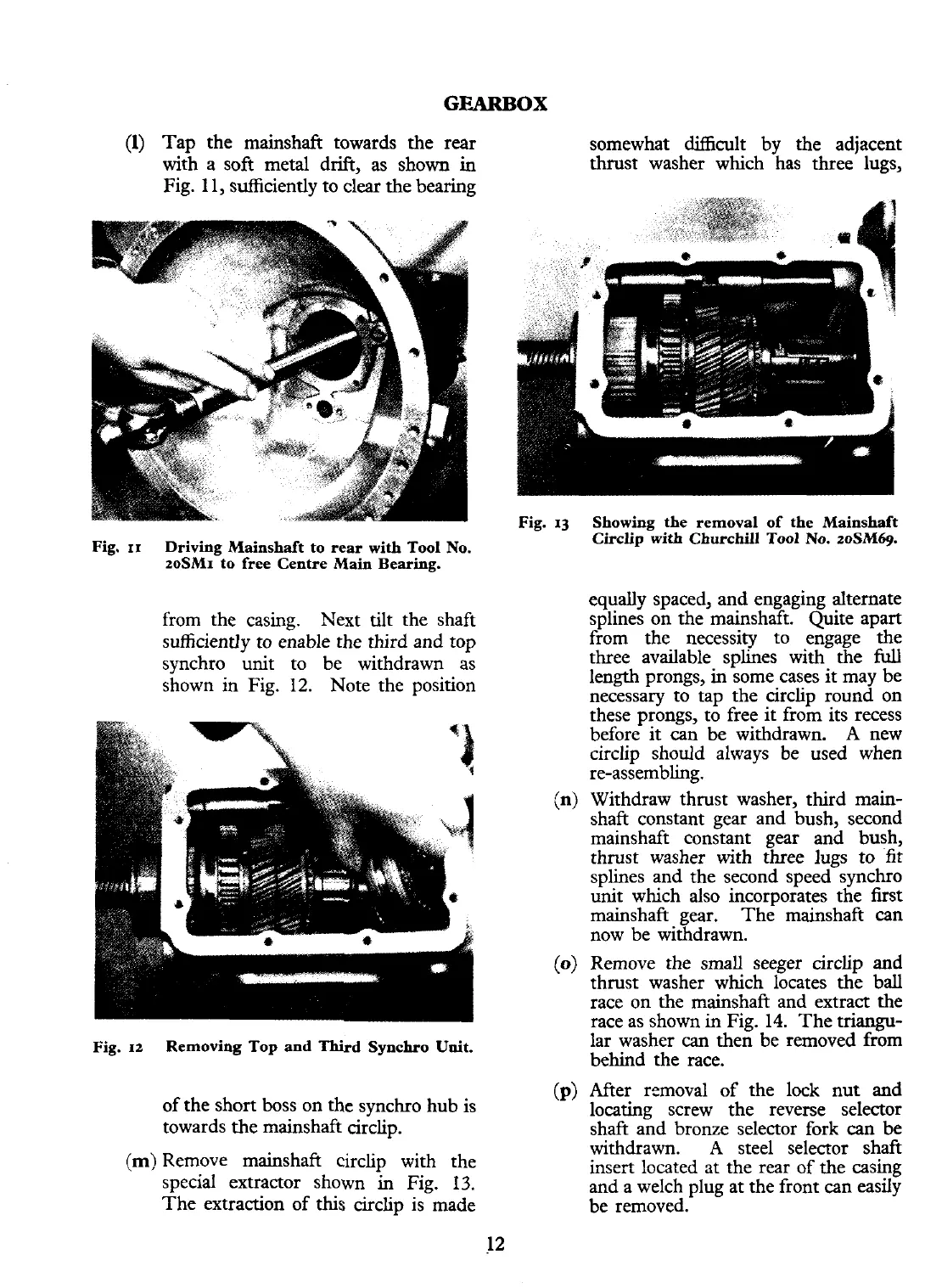

from the casing. Next tilt the shaft splines on the mainshaft. Quite apart

sufficiently to enable the third and top from the necessity to engage the

synchro unit to be withdrawn as three available splines with the

full

shown in Fig. 12. Note the position

length prongs, in some cases it may be

necessary to tap the

circlip round on

these prongs, to free it from its recess

%

before it can be withdrawn.

A

new

Fig.

12

Removing Top and Third Synchro Unit.

circlip should always be used when

re-assembling.

(n)

Withdraw thrust washer, third main-

shaft constant gear and bush, second

mainshaft constant gear and bush,

thrust washer with three lugs to

fit

splines and the second speed synchro

unit which also incorporates the first

mainshaft gear. The mainshaft can

now be withdrawn.

(0)

Remove the small seeger circlip

and

thrust washer which locates the ball

race on the mainshaft and extract the

race as shown in Fig.

14.

The

triangu-

lar washer

can

then be removed from

behind the race.

(p)

After removal of the lock nut and

of the short boss on the synchro hub is

locating screw the reverse selector

towards the mainshaft

arclip.

shaft and bronze selector fork

can

be

(m)

Remove mainshaft circlip with the

special extractor shown in Fig.

13.

The extraction of this circlip is made

withdrawn.

A

steel selector shaft

insert located at the rear of the casing

and a welch plug at the front can easily

be removed.

Loading...

Loading...