GEARBOX

INSTALLATION OF OVERDRIVE

I.

DIShUNTLING

the distance piece and finally the con-

stant speed gear

with

the boss towards

Remove the detachable floor pressing from

the distance piece.

around the gearbox. Remove the four bolts

(f

)

Position the

completed countershaft

connecting the propeller shaft to the

gear-

gear assembly in the bottom of the

box flange. Disconnect the speedometer

gear case and slide into position the

drive from the gearbox. Remove the rear thrust washer.

bottom nuts of rear mounting and jack up

engine sufficiently to allow removal of rear

(g)

For checking purposes the counter-

mounting. Remove the starter motor.

shaft should be fitted.

The counter-

Remove the clevis pin from the lever on

shaft gears (when new) have

an

end

the clutch operating shaft.

float of

.006"-.010".

(h)

After checking,the countershaft should

Remove the bolts from around the bell

be removed by pushing the needle re-

housing and detach the gearbox from the taining tube into the countershaft

engine.

gears and forcing the

layshaft out, after

The gearbox should now be dismantled and

which the gears will drop to the

the various gears and ball races examined

bottom of the gearbox casing.

for possible damage. Any parts which are

(i)

Fit the triangular washer, ball race,

damaged or suspect

in

any way should be distance washer and circlip to the new

replaced. mainshaft. Gripping the mainshaft

The mainshaft originally fitted will be re-

in the protected jaws of a vice,

placed by the special one supplied. To

assemble the gears on this shaft up to

ensure the future life of the Overdrive Unit

the main locating circlip, ensuring that

it is advisable to fit a new mainshaft

bear-

the recess for this is free for its

ing.

eventual entry by checking with half

the circlip previously used (a new one

2.

ASSEMBLY OF GEARBOX

will be required when re-assembling).

When a new 2nd or 3rd mainshaft gear

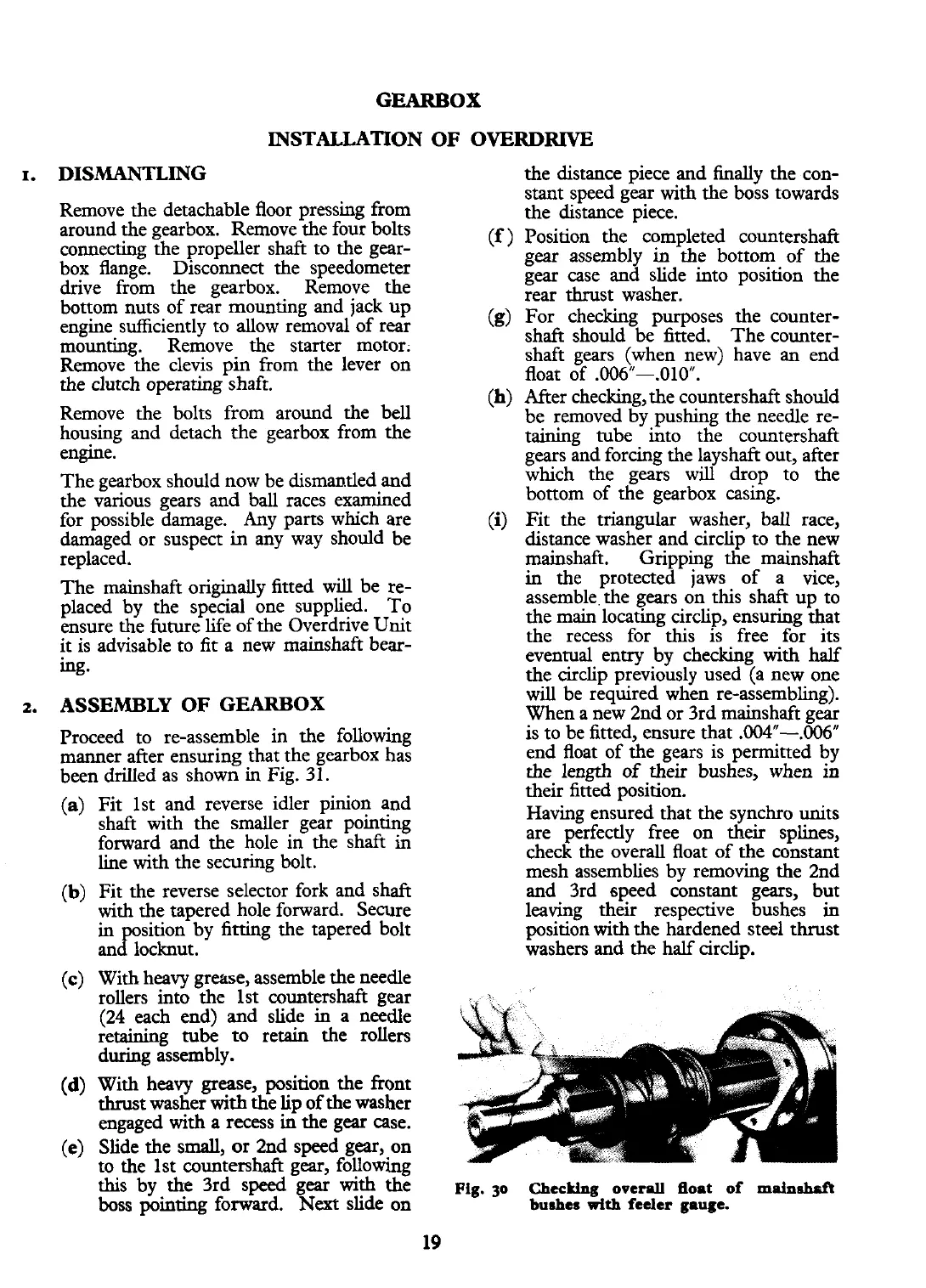

Proceed to re-assemble in the following

is to be fitted, ensure that

.004"-.006"

manner after ensuring that the gearbox has

end float of the gears is permitted by

been drilled as shown in Fig. 31.

the length of their bushes, when in

their fitted position.

(a)

Fit 1st and reverse idler pinion and

shaft with the smaller gear pointing

Having ensured that the synchro units

forward and the hole in the shaft in

are perfectly free on

their splines,

line with the securing bolt.

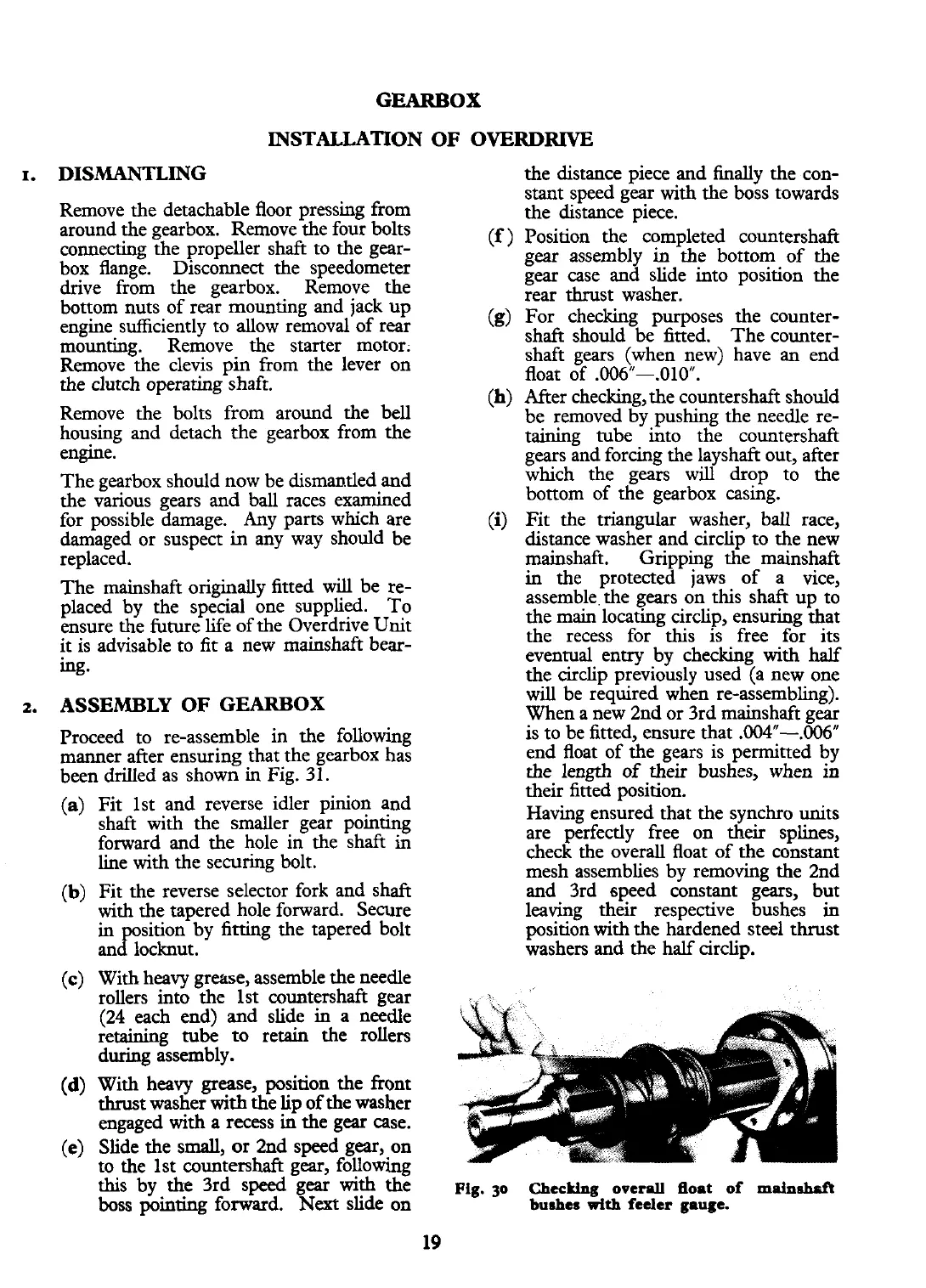

check the overall float of the constant

mesh assemblies by removing the 2nd

(b)

Fit the reverse selector fork and shaft

and 3rd speed constant gears, but

with the tapered hole forward. Secure leaving their respective bushes in

"d"

sition by fitting the tapered bolt

position

with

the hardened steel thrust

an locknut. washers and the half circlip.

(c) With heavy grease, assemble the needle

rollers into the 1st countershaft gear

(24

each end) and slide in a needle

retaining

tube

to retain the rollers

during assembly.

(d)

With heavy grease, position the front

thrust washer

with

the

lip

of the washer

engaged with a recess in the gear case.

(e)

Slide the small, or 2nd speed gear,.on

to the 1st countershaft gear, followmg

this by the 3rd speed gear

with

the

~ig.

jo

chec~lng

orera float of

rnPinshrft

boss pointing forward.

Next

slide on

bushes

with

feeler gauge.

19

Loading...

Loading...