GEARBOX

The end float can then be checked with

a

set of feeler gauges as shown in

Fig.

30.

The correct float should be

between .007" and .012".

Remove the mainshaft details remain-

ing on the shaft and begin the final

assembly.

Feed the shaft into the casing and

assemble the 2nd gear synchro unit,

the hardened steel thrust washer which

must be located on the

splines, the 2nd

constant gear with its bush, the 3rd

constant gear with bush, the front

hardened steel thrust washer and finally

fit the main locating circlip with a

special sleeved tool.

Withdraw the gearbox mainshaft,

with

the gears so far assembled, sufficiently

towards the rear to enable the assembly

to be tipped upwards, thus permitting

the 3rd and top synchro unit to be

fitted.

Tap the mainshaft assembly into

position and fit the constant pinion

assembly.

--A

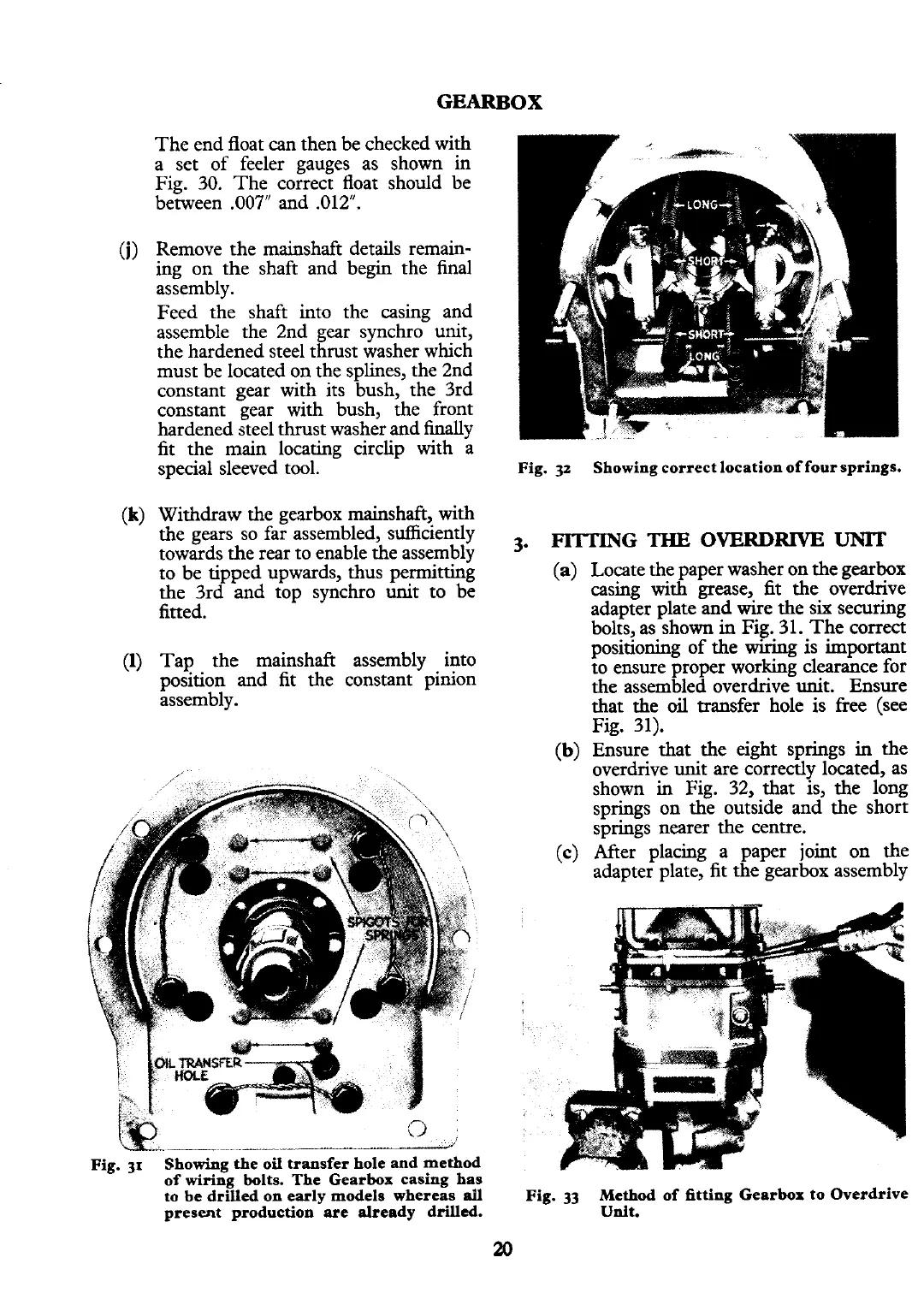

Fig.

31

Showing the oil transfer hole and method

of wiring bolts. The Gearbox casing has

to be drilled on early models whereas

d

present production are already drilled.

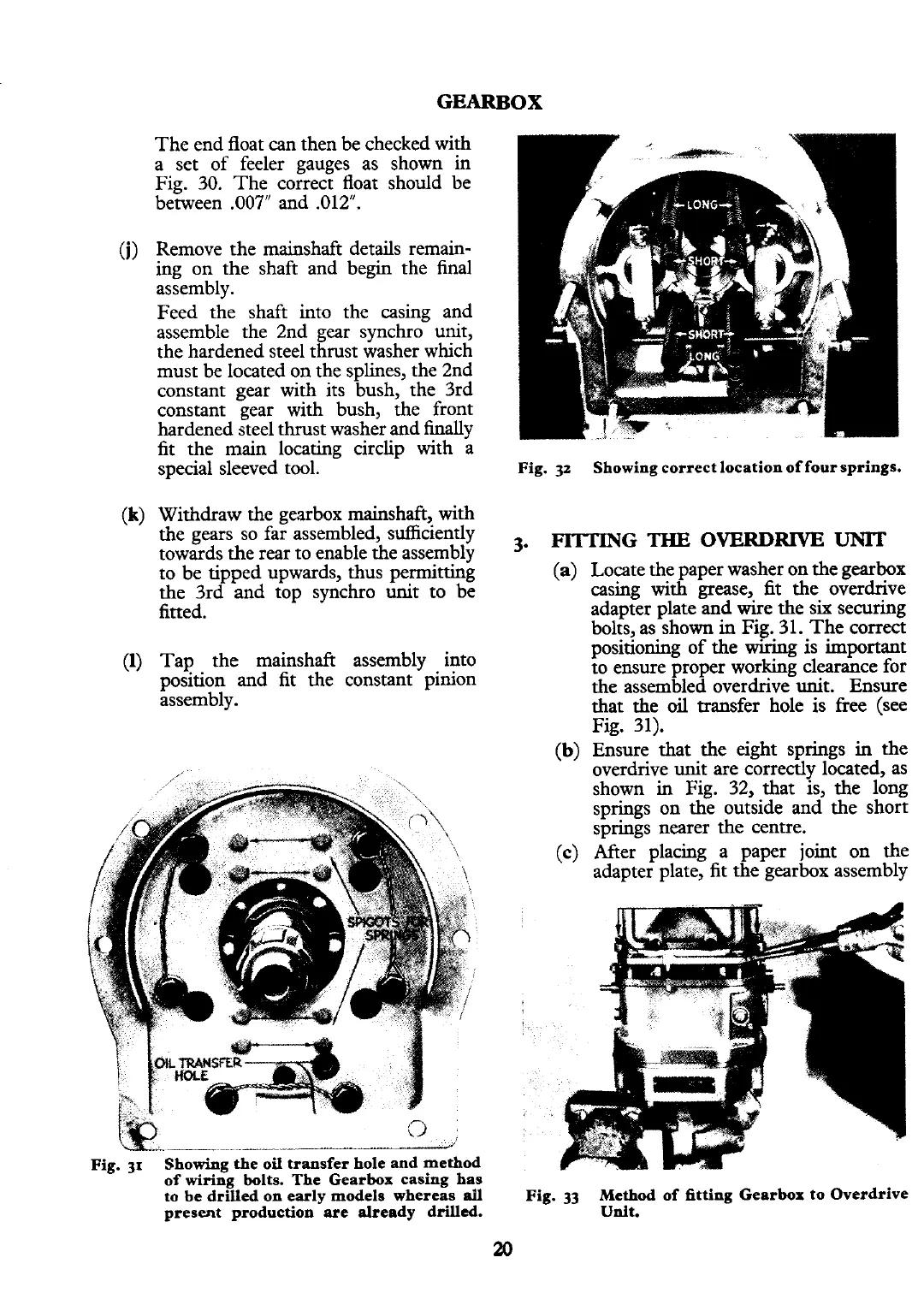

Fig.

32

Showing correct location of four springs.

3.

FITTING

THE

OVERDRIVE

UNIT

(a)

Locate the paper washer on the gearbox

casing

with

grease,

fit

the overdrive

adapter plate and wire the six securing

bolts, as shown

in

Fig. 31. The correct

positioning of the wiring is important

to ensure proper working clearance for

the assembled overdrive unit. Ensure

that the

oil

transfer hole is free (see

Fig. 31).

(b)

Ensure that the eight springs

in

the

overdrive unit are correctly located, as

shown in Fig. 32, that 'Is, the long

springs on the outside and the short

springs nearer the centre.

(c)

After placing a paper joint on the

adapter plate, fit the gearbox assembly

Fig.

33

Method of fitting Gearbox to Overdrive

Udt.

Loading...

Loading...