REAR

AXLE

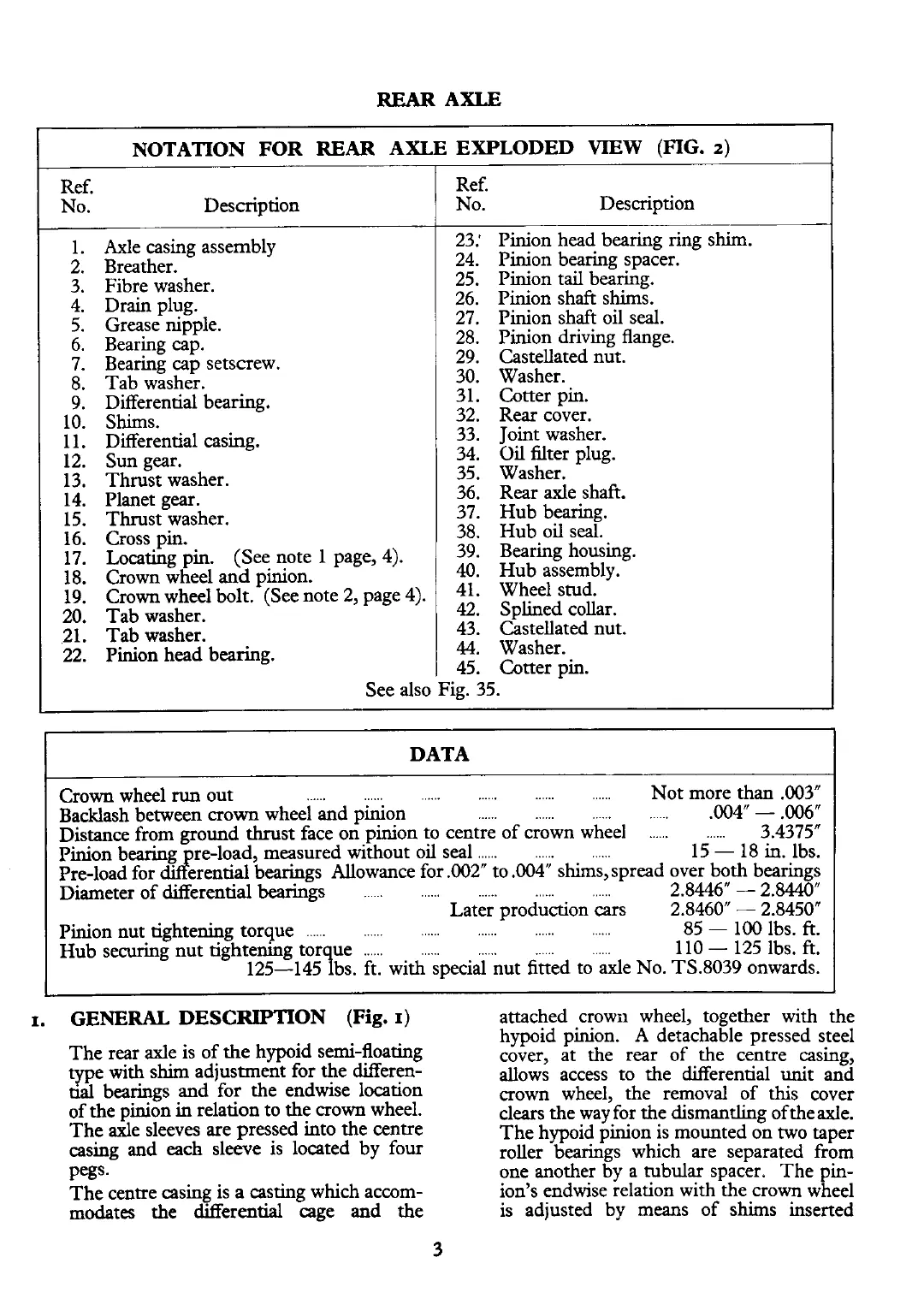

NOTATION FOR

REAR

AXLE EXPLODED

VIEW

(FIG.

2)

Ref.

No.

Description

Axle casing assembly

Breather.

Fibre washer.

Drain plug.

Grease nipple.

Bearing cap.

Bearing cap setscrew.

Tab washer.

Differential bearing.

-

Shims.

Differential casing.

Sun gear.

Thrust washer.

Planet gear.

Thrust washer.

Cross pin.

Locating pin. (See note

1

page, 4).

Crown wheel and pinion.

Crown wheel bolt. (See note 2, page 4).

Tab washer.

Tab washer.

Pinion head bearing.

Ref.

No. Description

23.' Pinion head bearing ring shim.

24. Pinion bearing spacer.

25. Pinion tail bearing.

26. Pinion shaft shims.

27. Pinion shaft oil seal.

28. Pinion driving flange.

29. Castellated nut.

30. Washer.

31. Cotter pin.

32. Rear cover.

33. Joint washer.

34. Oil filter plug.

35. Washer.

36. Rear axle shaft.

37. Hub bearing.

38. Hub oil seal.

39. Bearing housing.

40.

Hub assembly.

41. Wheel stud.

42.

Splined collar.

43. Castellated nut.

44. Washer.

45. Cotter pin.

See also '~i~. 35.

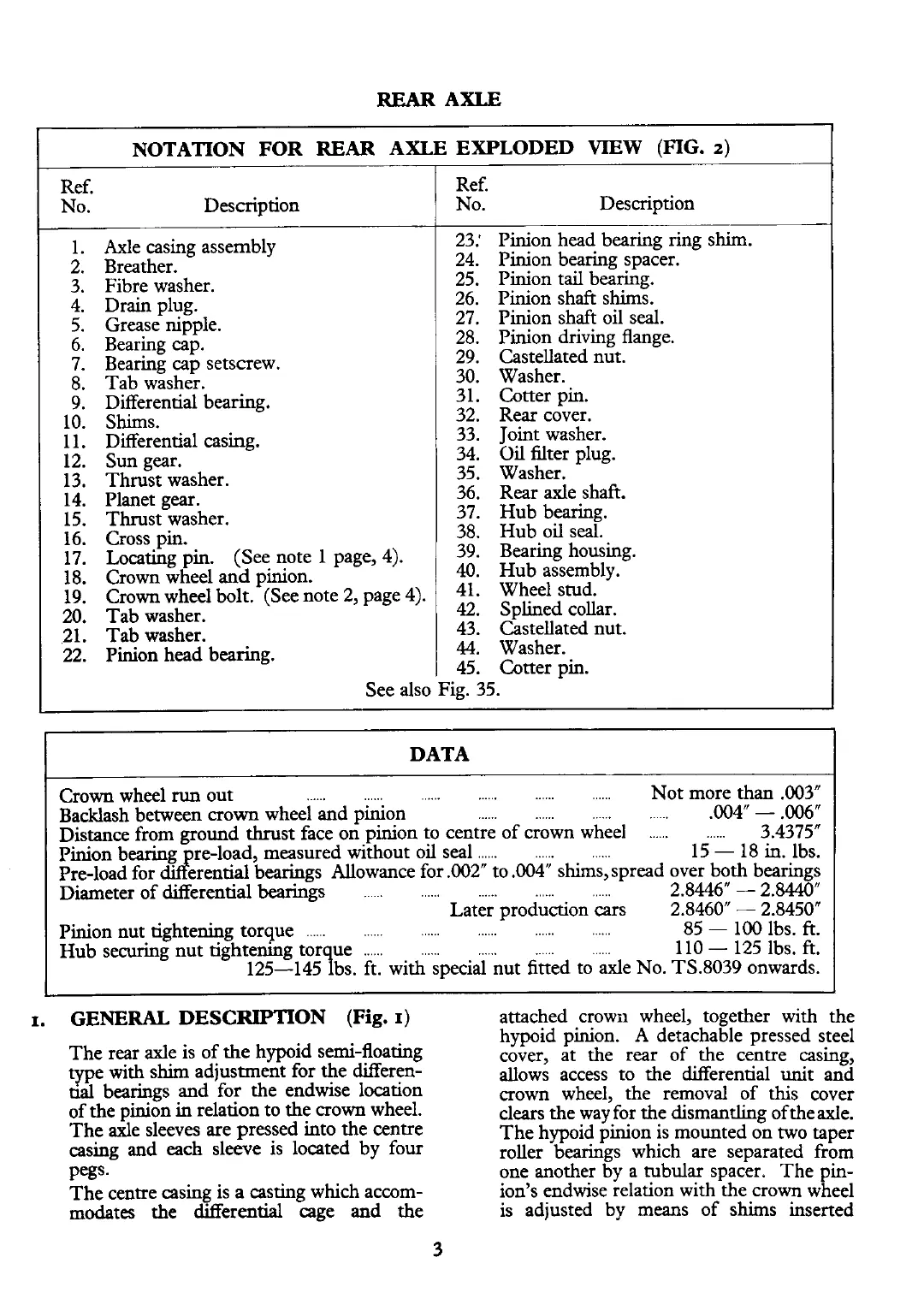

DATA

......

......

......

......

......

Crown wheel

run

out

......

Not more than .003"

......

......

......

......

Backlash between crown wheel and pinion

.004"

-

.M"

......

Distance from ground thrust face on pinion to centre of crown wheel

......

3.4375"

Pinion bearing re load, measured without oil seal

......

15

-

18 in. lbs.

Pre-load for derekal bearings Allowance for .W1" to

.OOii'

shimi,spread over both bearings

......

......

......

......

Diameter of differential bearings

...

2.8446"

-

2.8440"

Later production cars

2.8460"

-

2.8450"

......

......

......

......

Pinion nut tightening torque

............

85

-

100 lbs.

ft.

Hub securing nut tightemg tor ue

110

-

125 lbs.

ft.

125-145lbs.

fi:

withipecial'iut fiGed tohe No. TS.8039 onwards.

I.

GENERAL

DESCRIPTION

(Fig.

I)

The rear axle is of the hypoid semi-floating

pe with shim adjustment for the differen-

tlal

bearings and for the endwise location

of the pinion in relation to the crown wheel.

The axle sleeves are pressed into the centre

casing and each sleeve is located by four

Pegs.

The centre casing is a casting which accom-

modates the

differential cage and the

attached crown wheel, together with the

hypoid pinion.

A

detachable pressed steel

cover, at the rear of the centre casing,

allows access to the differential unit and

crown wheel, the removal of this cover

clears the way for the dismantling oftheaxle.

The

hypoid pinion is mounted on two taper

roller bearings which are separated from

one another by a tubular spacer. The pin-

ion's

endwise relation with the crown wheel

is adjusted by means of shims inserted

Loading...

Loading...