REAR

AXLE

between the

"

head

"

bearing outer ring

and the casing. Preloading of bearings is

adjusted by means of shims between the

spacer and tail bearing.

The differential casing contains two sun and

two planet wheels and also carries the crown

wheel, which is bolted in position by ten

bolts passing through the casing and into

tapped holes in the back of the wheel itself.

NOTE

2

:

Fig.

1.

The crown wheel is

attached to the differential casing by

bolts locked by tab washers. The crown

wheel showed a tendency to work

loose after exacting rally acceleration

and reversing gear tests and to ob-

viate this possibility the

h"

UNF

attachment bolts were replaced by

8"

UNF in axles numbered TS.4731

onwards.

The two planet wheels are mounted on a

cross spindle, this spindle being provided

with a hole at one end and located by a pin

passing through the hole and the differen-

tial casing.

NOTE

1

:

Fig.

1.

The locating pin used

has a

"

stepped

"

shape but this is to

be changed in the near future to the

"parallel" type pin as shown in the

main illustration. Incorporated in

axle No. TS.6260 onwards.

The axle shafts are splined at both ends.

The inner end fitting into the sun wheels

and the outer extremity accommodating the

wheel bearing and hub. The hub is

secured to the splined end of the axle shaft

by means of a splined taper collar, a shaped

washer and a castellated nut.

The wheel bearing is accommodated

in

the

axle sleeve and

a

housing which is bolted to

the flanged end of each axle tube. The inner

portion of the wheel bearing is gripped

between the hub and a flange on the axle

shaft.

The differential casing is mounted on two

taper roller bearings, the position of these

being adjusted by means of shims inter-

posed between them and the casing itself.

The disposition of these shims decides the

crown wheel and pinion depth of engage-

ment and the thickness of these the

amLunt

of pre-loading.

2.

TO

REMOVE

HUBS

(a)

Remove the nave plate.

(b)

Withdraw the split pin from end of

axle shaft. Partly release the torque on

the castellated hub securing nut.

(c)

Jack up the car, remove the castellated

nut, the road wheel and by the with-

drawal of the two countersunk set-

screws remove the brake drum.

(d)

Remove the washer and the splined

taper collar from the axle shaft.

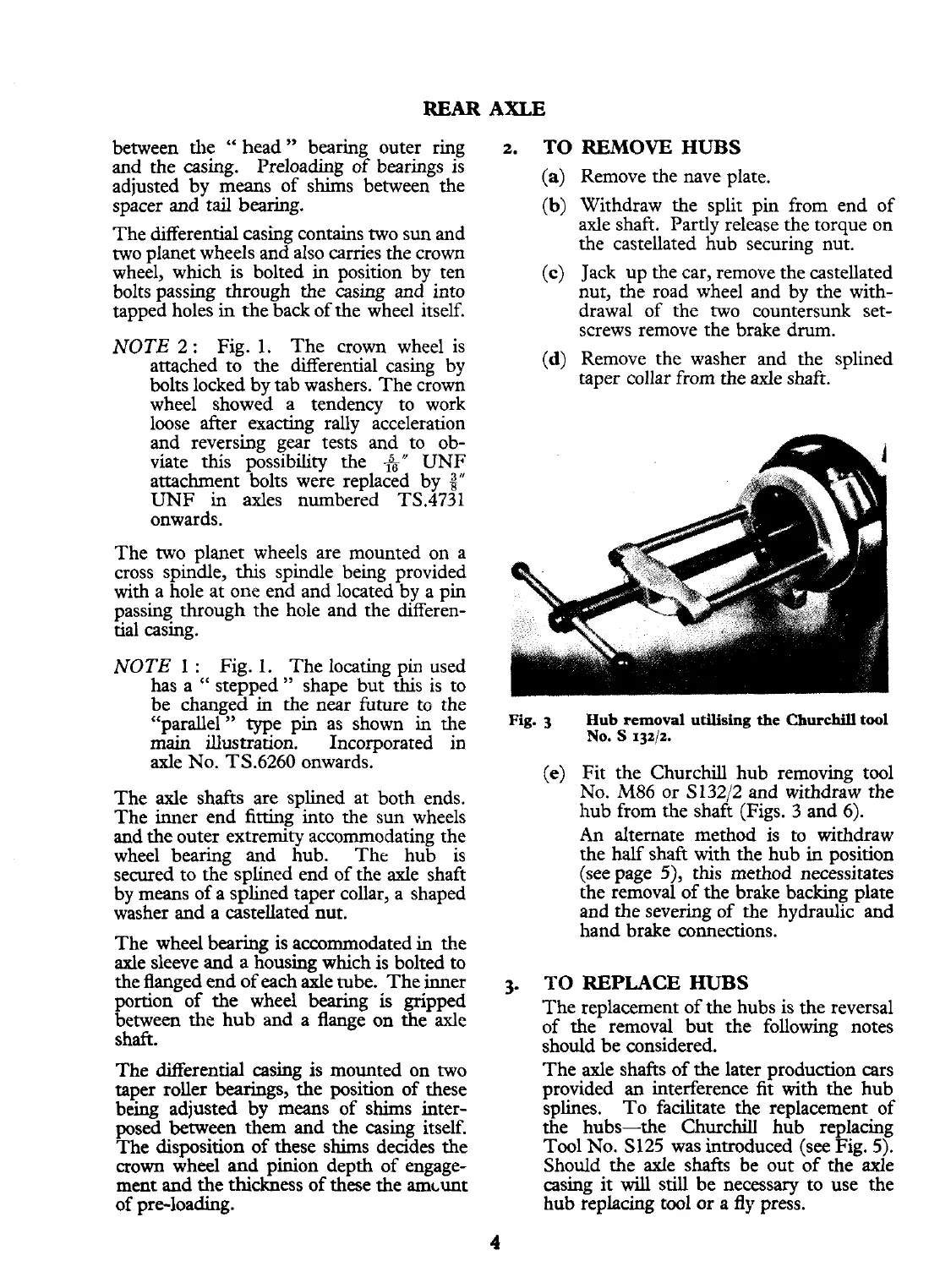

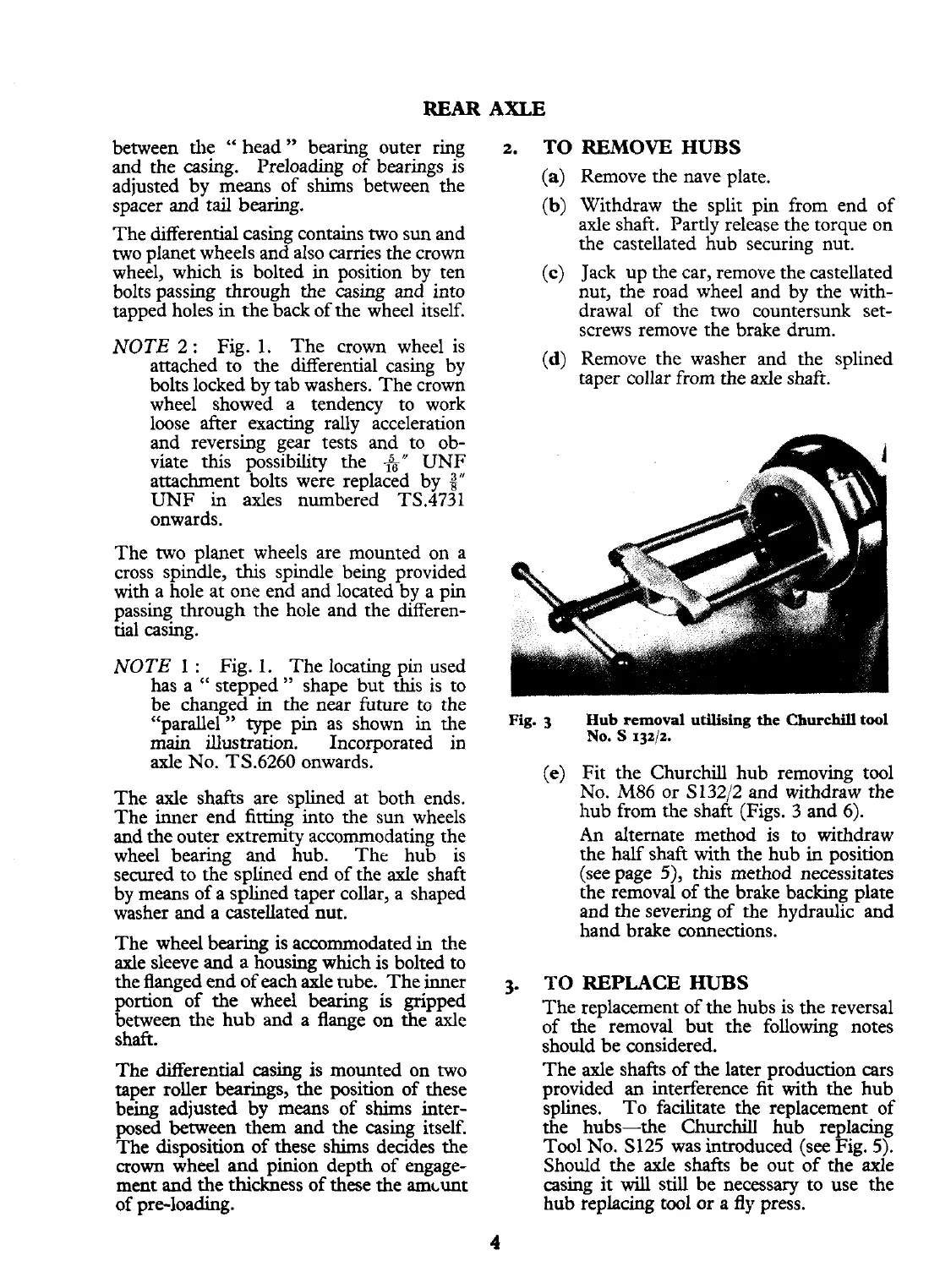

Fig.

3

Hub

removal

utilising

the

Churchill

tool

NO.

S

132/2.

(e)

Fit the Churchill hub removing tool

No. M86 or S13212 and withdraw the

hub from the shaft (Figs. 3 and 6).

An

alternate method is to withdraw

the half shaft with the hub in position

(see page

5),

this method necessitates

the removal of the brake backing plate

and the severing of the hydraulic and

hand brake connections.

3.

TO

REPLACE

HUBS

The replacement of the hubs is the reversal

of the removal but the following notes

should be considered.

The axle shafts of the later production cars

provided an interference fit with the hub

splines. To facilitate the replacement of

the hubs-the Churchill hub replacing

Tool No. S125 was introduced (see Fig. 5).

Should the axle shafts be out of the axle

casing it

will

still be necessary to use the

hub replacing tool or a

fly

press.

Loading...

Loading...