REAR

AXLE

4.

TO REMOVE HUBS (Centre lock

type) (Fig. 35)

(a)

Jack up the car and remove the hub

cap by tapping the lugs with a copper

faced mallet. Remove the road wheel.

5.

(b)

Remove the split pin through the

aperture in the barrel of the hub.

(c)

Remove the hub securing nut from the

axle shaft.

It

may be necessary to

replace the wheel and lower the car

when torque is applied to the nut.

After removing the nut withdraw the

washer and splined collar.

(d)

By inserting a screwdriver blade into

the cut of the split tapered collar, the

collar

will

expand and allow it to be

withdrawn from the hub.

Remove the two countersunk brake

drum securing screws and withdraw

the brake drum.

Fit the Churchill hub removing

Tool No. S132 and remove the

hub.

It

should be remembered

that the hubs have right or left-hand

threads and care must be exercised

when selecting the removal rings.

(See Fig.

4.)

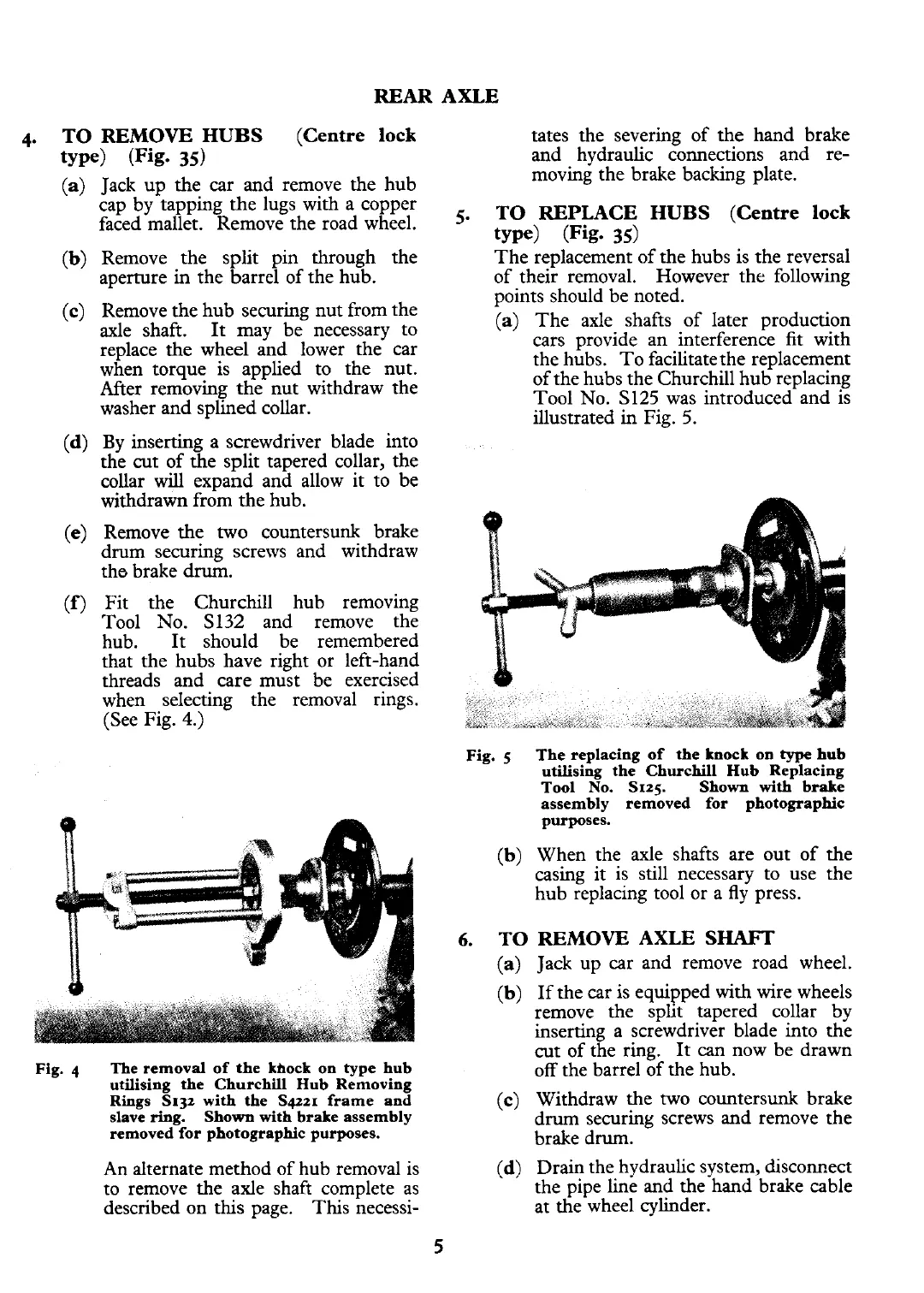

Fig.

4

The removal of the khock on type hub

utilising the Churchill Hub Removing

Rings S132 with the Sqtzr frame and

slave ring.

Shown with brake assembly

removed for photographic purposes.

An

alternate method of hub removal is

to remove the axle shaft complete as

described on this page. This necessi-

tates the severing of the hand brake

and hydraulic connections and re-

moving the brake backing plate.

TO REPLACE HUBS (Centre lock

type) (Fig. 35)

The replacement of the hubs is the reversal

of their removal. However the following

points should be noted.

(a)

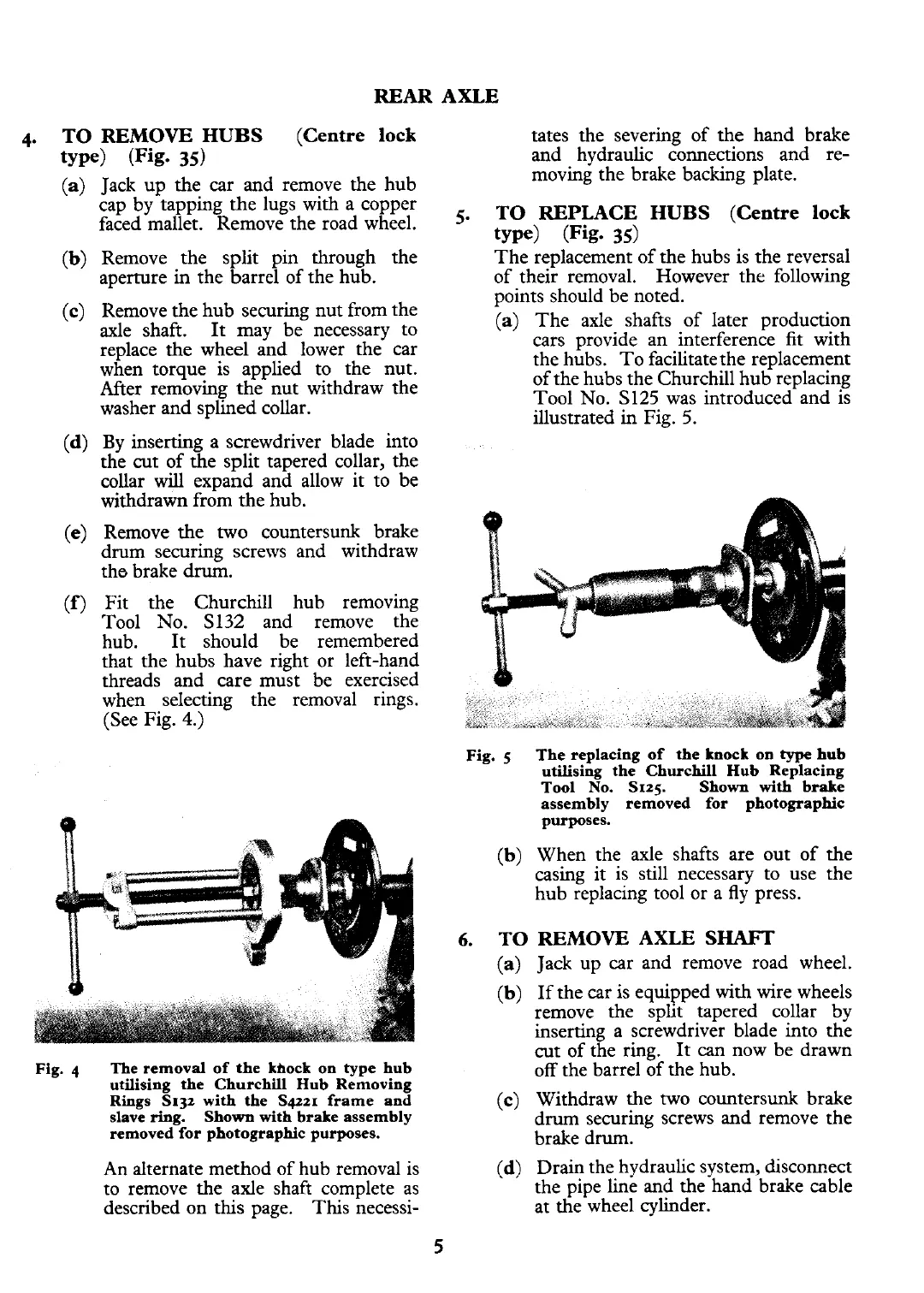

The axle shafts of later production

cars provide an interference fit with

the hubs. To facilitatethe replacement

of the hubs the Churchill hub replacing

Tool No. S125 was introduced and is

illustrated in Fig. 5.

Fig.

S

The replacing of the knock on

type

hub

utilising the Churchill Hub Replacing

Tool No.

S125 Shown with brake

assembly removed for photographic

purposes.

(b)

When the axle shafts are out of the

casing it is still necessary to use the

hub replacing tool or a

fly

press.

6.

TO REMOVE AXLE SHAFT

(a)

Jack up car and remove road wheel.

(b)

If the car is equipped with wire wheels

remove the split tapered collar by

inserting a screwdriver blade into the

cut of the ring. It

can

now be drawn

off the barrel of the hub.

(c)

Withdraw the two countersunk brake

drum securing screws and remove the

brake drum.

(d)

Drain

the hydraulic system, discomea

the pipe line and the hand brake cable

at the wheel cylinder.

Loading...

Loading...