REAR

AXLE

9.

TO

REPLACE

THE

AXLE

If a replacement axle is being fitted it will

be necessary to remove the complete brake

assemblies at the axle ends.

It is not necessary to remove the hubs,

for these

can

be removed with the half

shafts and brake backing plates.

The axle must be tilted during the fitting

operations and filling the axle with oil

should be delayed until the axle has been

fitted to the car.

The fitting is the reversal of the removal.

For the bleeding of the hydraulic system

see

"

Brakes-Section R."

10.

TO

DISMANTLE

the axle is going to be completely

dismantled the hubs

can

be removed at

a later stage, which means that the

half shafts, hubs, brake backing plates,

etc., must be removed as an assembly.

(d)

Remove brake shoes and return springs.

(e)

Withdraw the brake backing plates

after removal of the eight bolts, spring

washers and nyloc nuts, four from

either back plate. Further dismantling

of the brake

backing plates only require

the removal of the hydraulic wheel

cylinders and anchor blocks, the latter

being secured by spring washers and

two nuts, the former

can

be withdrawn

provided the hydraulic connections,

rubber dust sealing boots, etc., have

-

Drain oil. been removed.

Remove wheel securing cones (wire

(f)

The half shafts

can

now be withdrawn

wheel hubs only).

This enables the

from the axle

casing,the bearing hous-

brake drum securing screws to be

ings tapped off the bearings and the

removed and the drums withdrawn. bearines withdrawn with a suitable

"

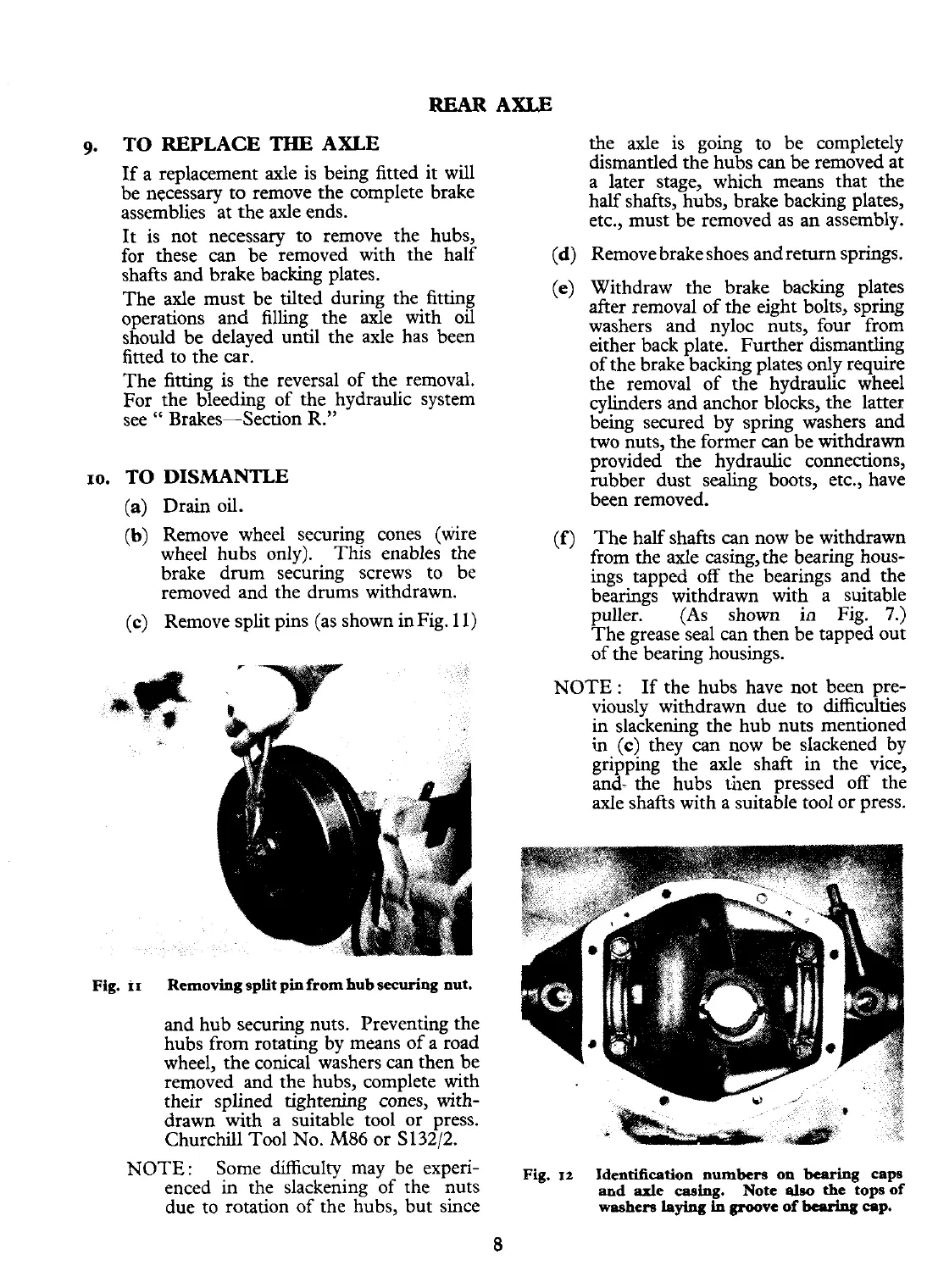

Remove split pins (as shown in Fig. 11) puller. (As shown in Fig.

7.)

The grease seal can then be tapped out

of the bearing housincs.

Fig.

ir

Removing split pin from hub securing nut.

and hub securing nuts. Preventing the

hubs from rotating by means of a road

wheel, the conical washers can then be

removed and the hubs, complete with

their

splined tightening cones, with-

drawn with a suitable tool or press.

Churchill Tool No.

M86

or S132/2.

NOTE:

Some difficulty may be experi-

enced

in

the slackening of the nuts

due to rotation of the hubs, but since

NOTE

:

If the hubs have not been pre-

viously withdrawn due to difficulties

in slackening the hub nuts mentioned

in

(c)

they can now be slackened by

gripping the axle shaft in the vice,

and- the hubs then pressed off the

axle shafts with a suitable tool or press.

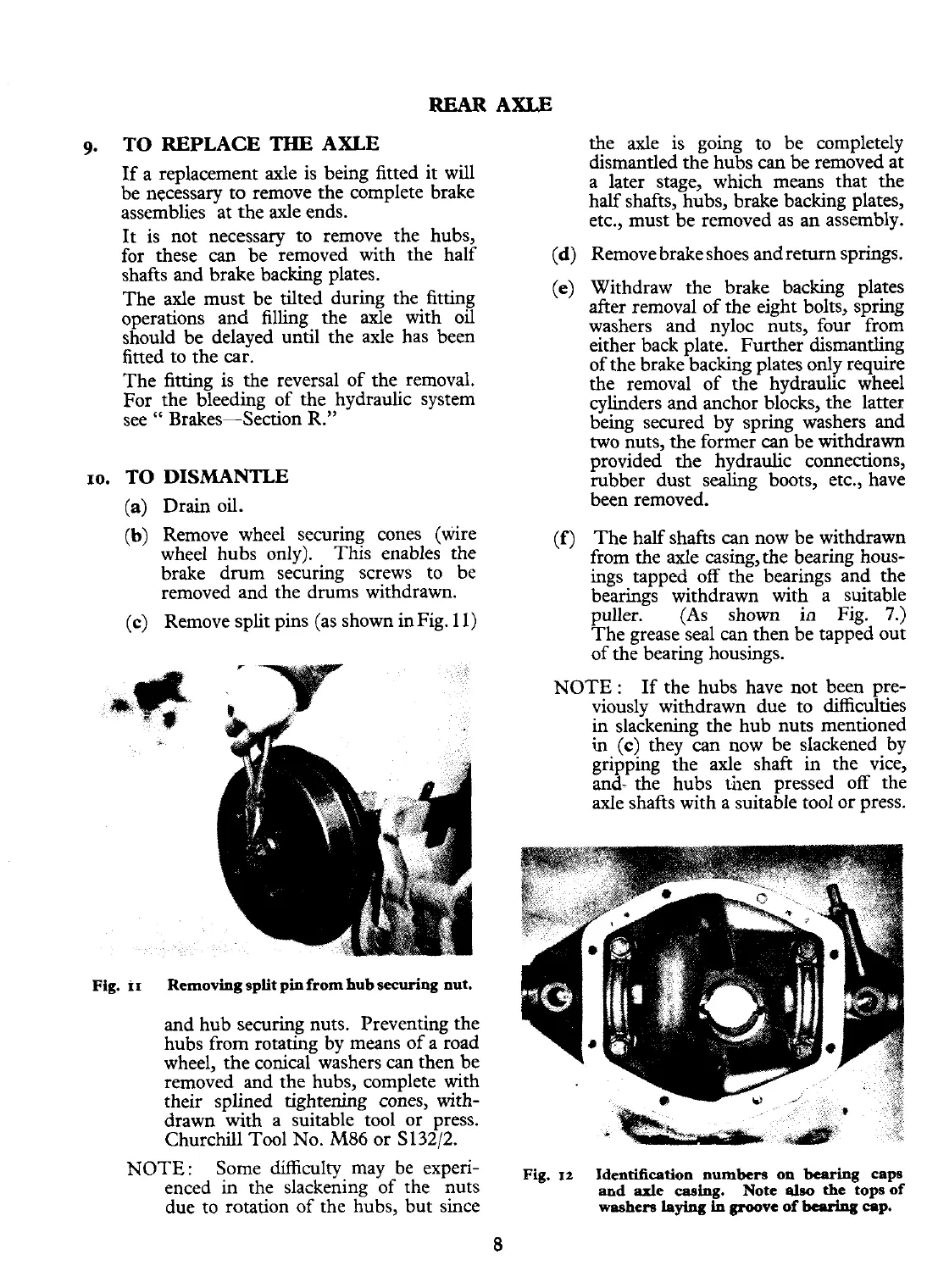

Fig.

12

Identification numbers on

bearing

caps

and

axle

casing.

Note

also

the tops of

washers

laying

in

groove

of

beprlns

cap.

Loading...

Loading...