REAR

AXLE

Remove axle centre casing cover and

joint after withdrawal of eight setscrews.

K

4

Remove the differential bearing caps,

n

notinnthe markings stamped on the tor,

of these and the c&resp&dingly abuG-

ing portions of the casing. The existing

relation between the caps and casing

must be retained when re-assembling.

Fig. 12 shows example of markings.

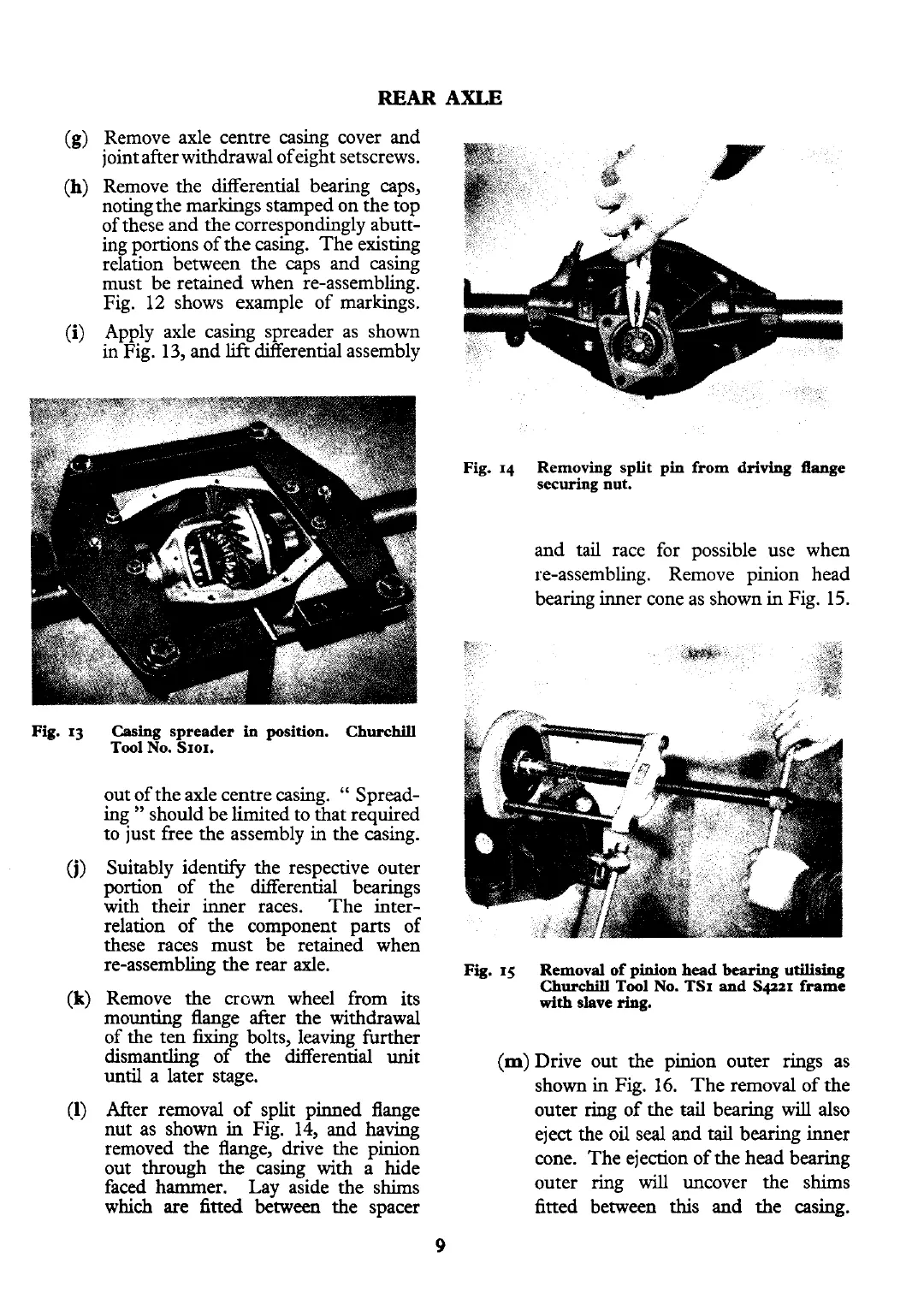

Apply axle casing spreader as shown

in Fig.

13,

and

lift

differential assembly

Fig. 13 Casing spreader

in

position.

Churchill

Tool

No. SIOI.

out of the axle centre casing.

"

Spread-

ing

"

should be limited to that required

to just free the assembly

in

the casing.

Suitably identify the respective outer

portion of the differential bearings

with their inner races. The inter-

relation of the component parts of

these races must be retained when

re-assembling the rear axle.

(k)

Remove the crown wheel from its

mounting flange after the withdrawal

of the ten fixing bolts, leaving further

dismantling of the differential unit

until a later stage.

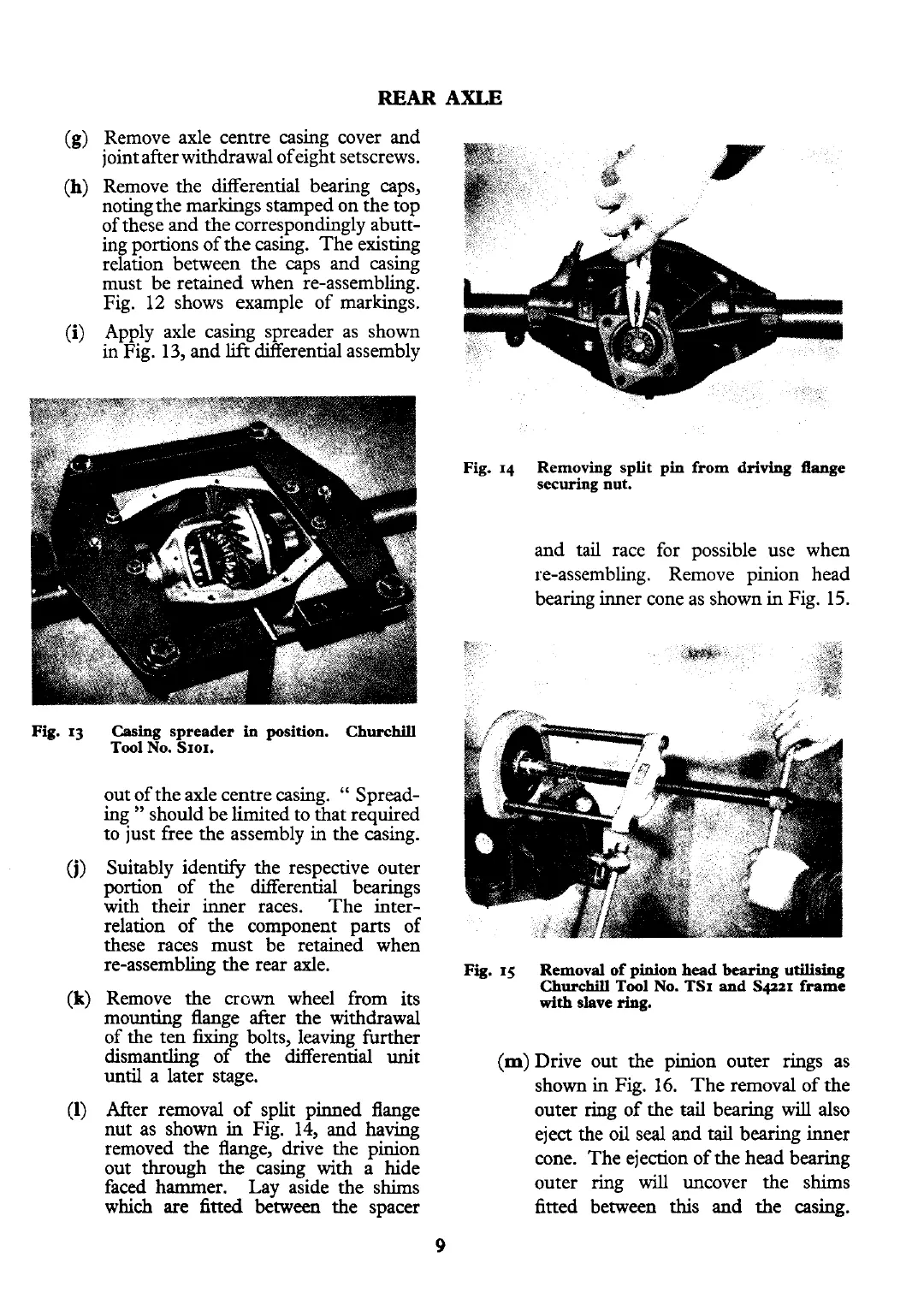

(1)

After removal of split pinned flange

nut as shown in Fig. 14, and having

removed the flange, drive the pinion

out through the casing with a hide

faced hammer. Lay aside the shims

which are

fitted

between

the spacer

Fig.

14

Removing split pin from driving flange

securing nut.

and tail race for possible use when

re-assembling. Remove pinion head

bearing inner cone as shown in Fig. 15.

Fig.

15

Removal of pinion

head

bearing

utilising

Churchill

Tool No. TSI

and

Sqzzr frame

with

slave

ring.

(m)

Drive out the pinion outer rings as

shown in Fig.

16.

The removal of the

outer

ring

of the

&

bearing

will

also

eject the oil seal and

tail

bearing inner

cone. The ejection of the head bearing

outer ring

will

uncover the shims

fitted between

this

and the casing.

Loading...

Loading...