REAR

AXLE

Driving

out pinion

bearing

outer

rings

utilising

Churchill

Tool

No.

zoSM

FT71.

These shims should be laid aside with

the component parts of this bearing

as a guide when re-assembling.

Replace the differential assembly in

the axle casing and release the tension

from the axle casing spreader.

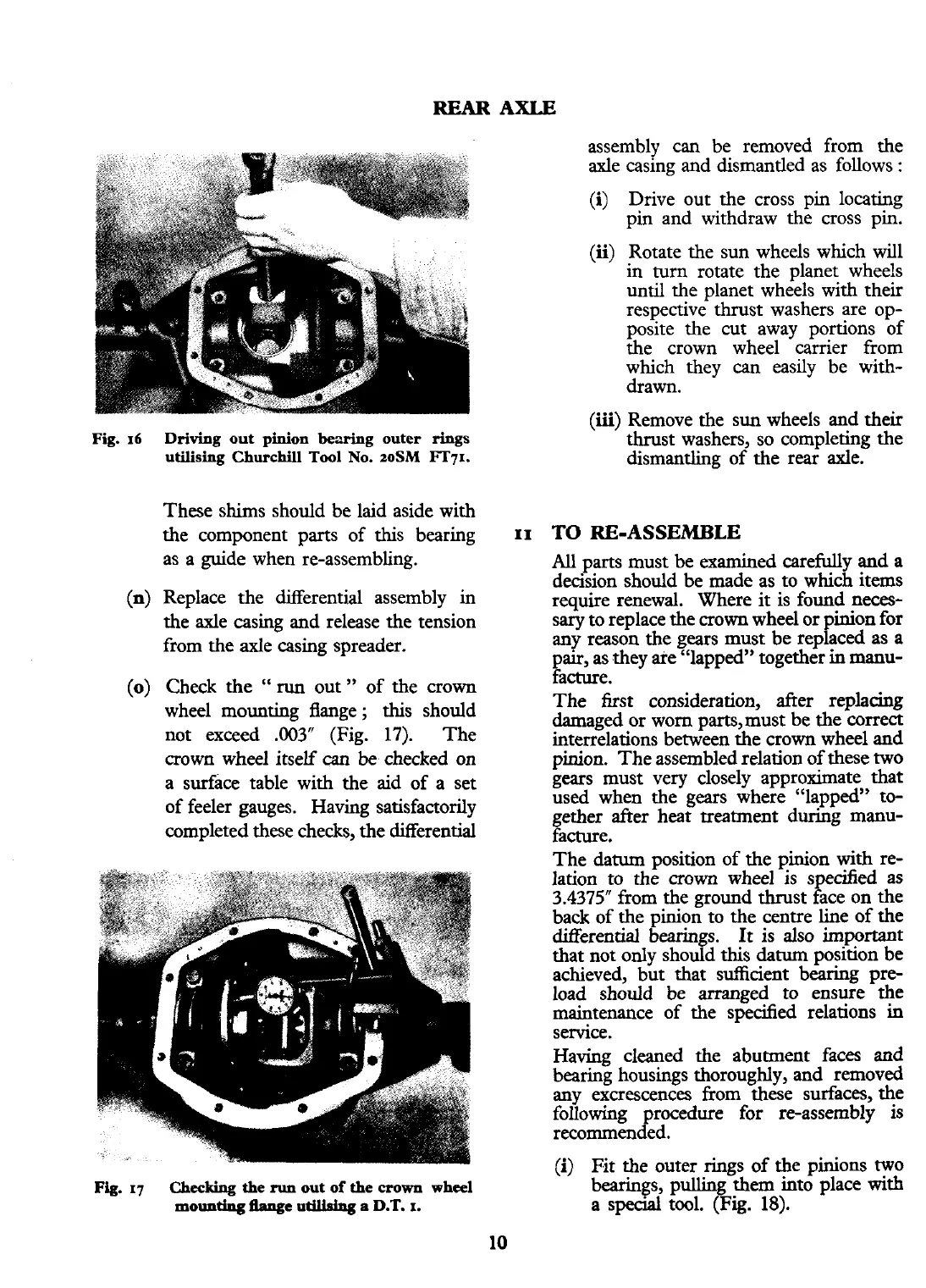

Check the

"

run

out" of the crown

wheel mounting flange; this should

not exceed

.003"

(Fig.

17).

The

crown wheel itself

can

be

checked on

a surface table with the aid of a set

of feeler gauges. Having satisfactorily

completed these checks, the differential

Fig.

17

Checking

the

run

out of

the

crown

wheel

mouutkrg

we

utilkhg

a

D.T.

I.

assembly

can

be removed from the

axle casing and dismantled as follows

:

(i)

Drive out the cross pin locating

pin and withdraw the cross pin.

(ii)

Rotate the sun wheels which will

in turn rotate the planet wheels

until the planet wheels with their

respective

thrust washers are op-

posite the cut away portions of

the crown wheel carrier from

which they

can

easily be with-

drawn.

(iii)

Remove the sun wheels and their

thrust washers, so completing the

dismantling of the rear axle.

TO

RE-ASSEMBLE

All

parts must be examined carefully and a

decision should be made as to which items

require renewal. Where

it

is found neces-

sary to replace the crown wheel or pinion for

any reason the gears must be replaced as a

pair, as they

afe "lapped" together in manu-

facture.

The first consideration, after replacing

damaged or worn parts, must be the correct

interrelations between the crown wheel and

pinion. The assembled relation of these two

gears must very closely approximate that

used when the gears where "lapped" to-

gether after heat treatment during manu-

facture.

The

datum

position of the pinion with re-

lation to the crown wheel is specified as

3.4375" from the ground thrust face on the

back of the pinion to the centre line of the

differential bearings. It is also important

that not only should this datum position be

achieved, but that sufficient bearing pre-

load should be arranged to ensure the

maintenance of the specified relations in

service.

Having cleaned the abutment faces and

bearing housings thoroughly, and removed

any excrescences from these surfaces, the

following procedure for re-assembly is

recommended.

(i)

Fit the outer rings of the pinions two

bearings, pulling them into place

with

a

special

tool.

(Fig.

18).

Loading...

Loading...