REAR

Although the packing shims are sup-

plied to nominal thicknesses, the dimen-

sions should be measured with a

micrometer gauge. It is important that

no damaged shims are used and that

they are thoroughly cleaned before

measurement. (Fig. 21.)

Remove the pinion setting gauge,

dummy pinion and pinion bearing

outer rings.

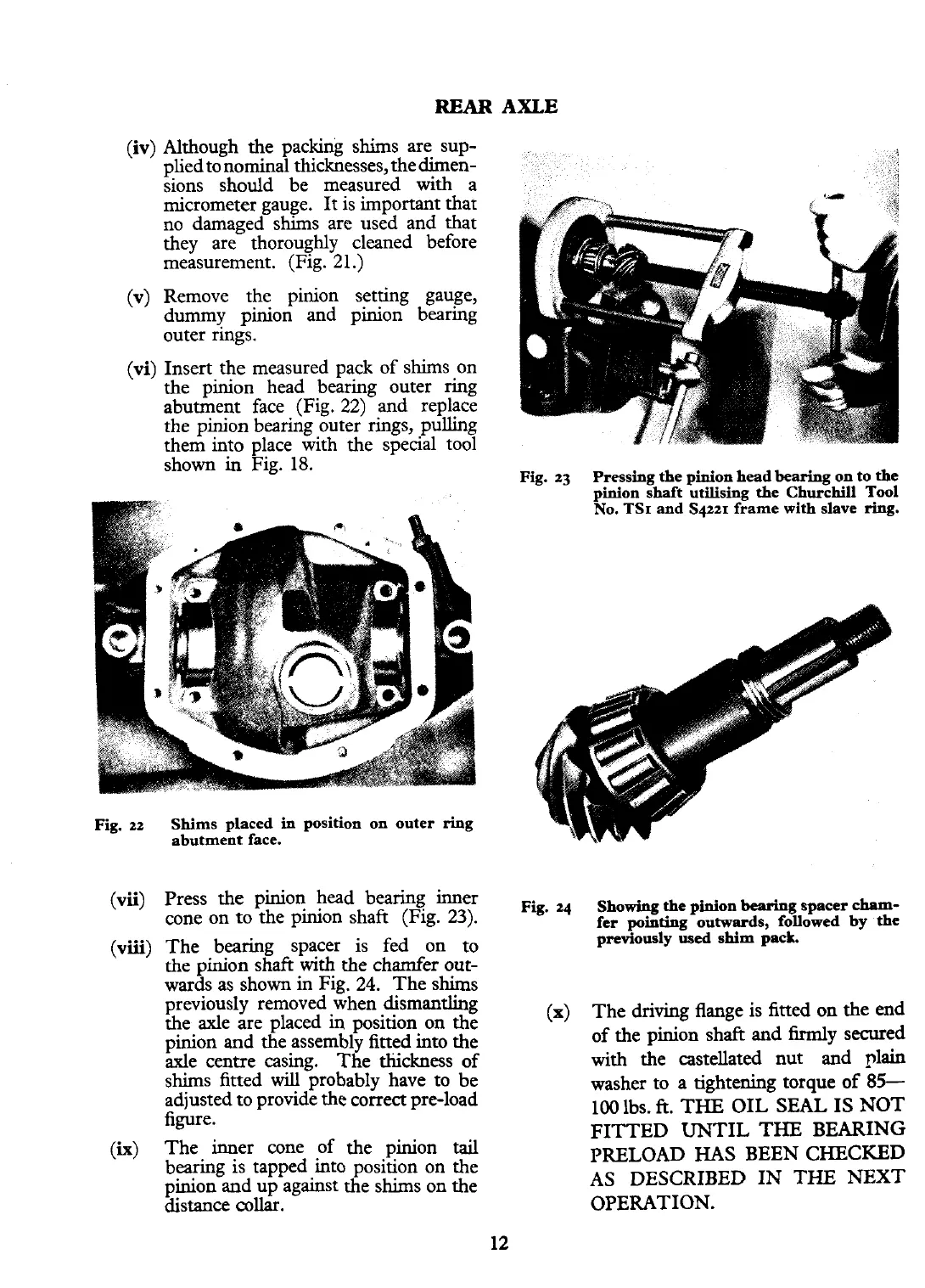

Insert the measured pack of shims on

the pinion head bearing outer ring

abutment face (Fig. 22) and replace

the pinion bearing outer rings, pulling

them into place with the special tool

shown

in

Fig. 18.

Fig.

22

(vii)

(viii)

(h)

Shims placed in position on outer ring

abutment face.

Press the pinion head bearing inner

cone on to the pinion shaft (Fig.

23).

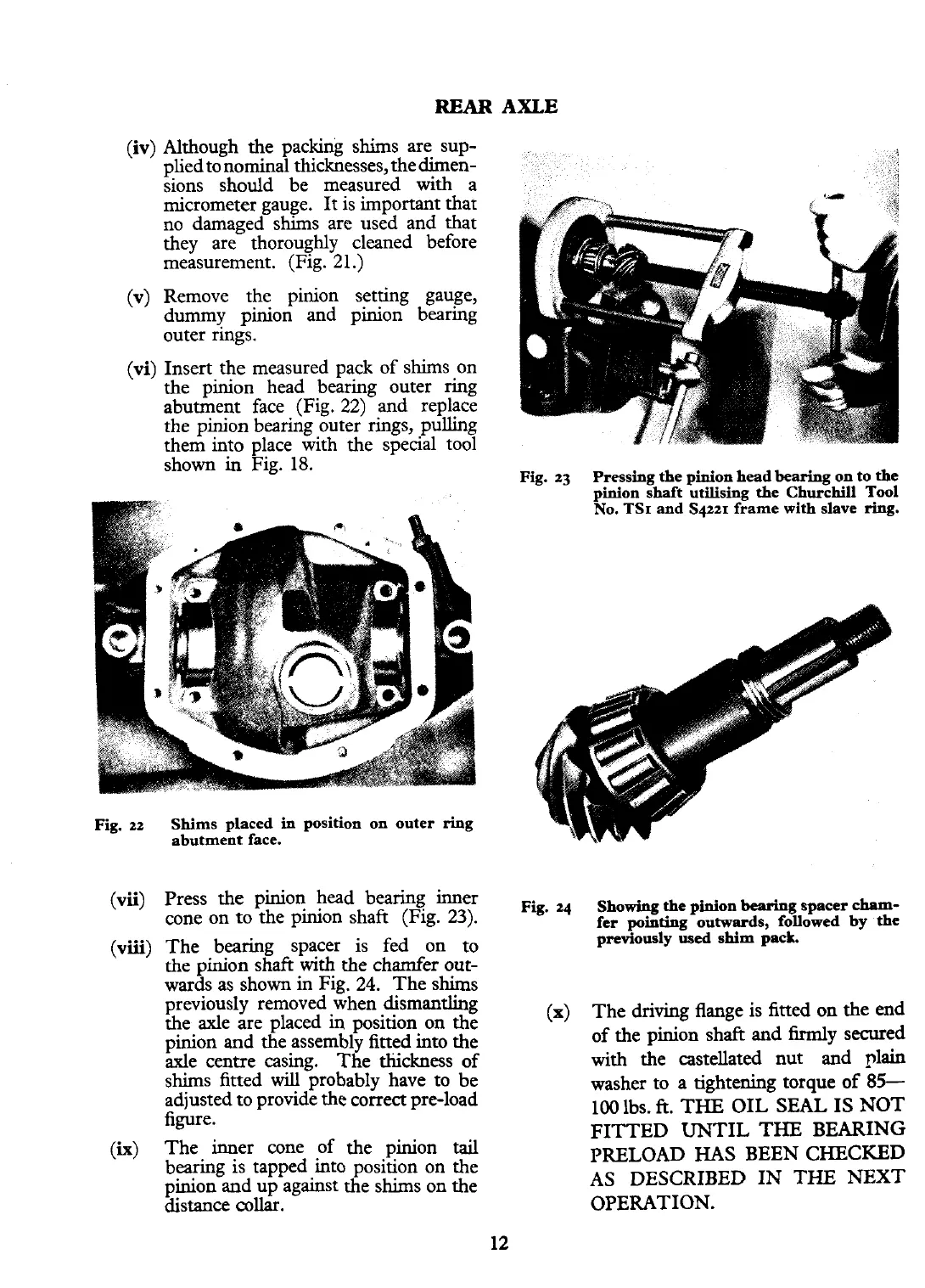

The bearing spacer is fed on to

the pinion shaft with the chamfer out-

wards as shown in Fig. 24. The shims

previously removed when dismantling

the axle are placed

in

position on the

pinion and the assembly fitted into the

axle centre casing. The thickness of

shims fitted

will

probably have to be

adjusted to provide the correct pre-load

figure.

The inner cone of the pinion

tail

bearing is tapped into position on the

pinion and up against the shims on the

distance

collar.

AXLE

Fig.

23

Pressing the pinion head bearing on to the

pinion shaft utilising the Churchill Tool

No.

TSI

and S4221 frame with slave

ring.

Fig.

24

Showing

the

pinion bearing spacer cham-

fer pointing outwards, followed

by

the

previously

used

shim pack.

(X)

The driving flange is fitted on the end

of the pinion shaft and firmly secured

with the castellated nut and plain

washer to a tightening torque

of

85-

100

lbs.

ft.

THE OIL SEAL IS

NOT

FITTED UNTIL THE BEARING

PRELOAD

HAS

BEEN CHECKED

AS DESCRIBED IN THE

NEXT

OPERATION.

Loading...

Loading...