REAR

AXLE

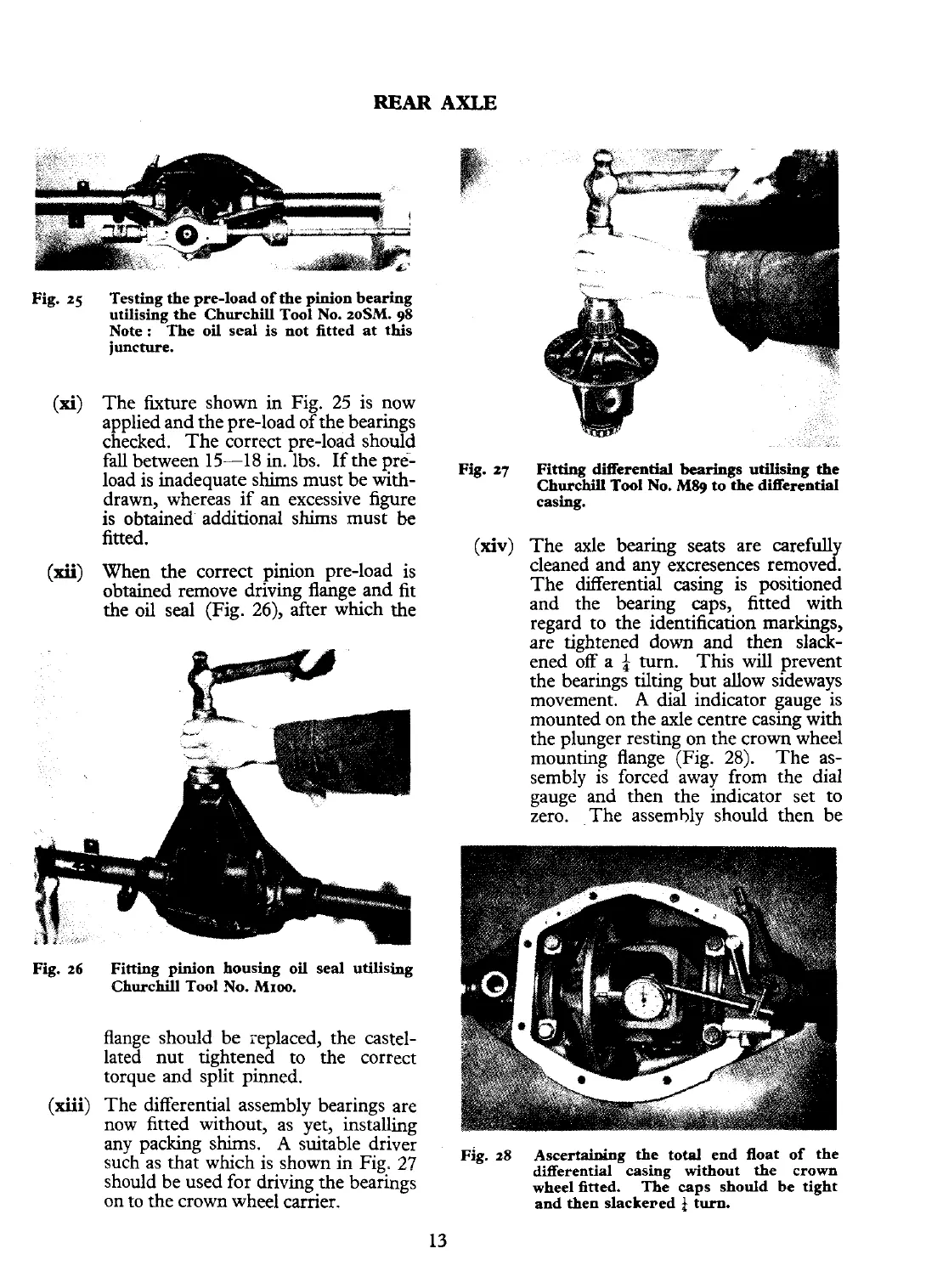

Testing the pre-load of the pinion bearing

utilising the Churchill Tool No. 2oSM.

98

Note: The oil seal is not fitted at this

juncture.

The fixture shown in Fig.

25

is now

a~~lied and the

re-load

of the bearings

&cked. The correct pre-load should

fall between

15-18

in. lbs. If the pre-

load is inadequate shims must be with-

drawn, whereas if an excessive figure

is obtained additional shims must be

fined.

When the correct pinion pre-load is

obtained remove driving flange and

fit

the oil seal (Fig.

26),

after which the

Fig. 26

Fitting pinion housing oil seal utilising

Churchill Tool No. Mmo.

flange should be replaced, the castel-

lated nut tightened to the correct

torque and split pinned.

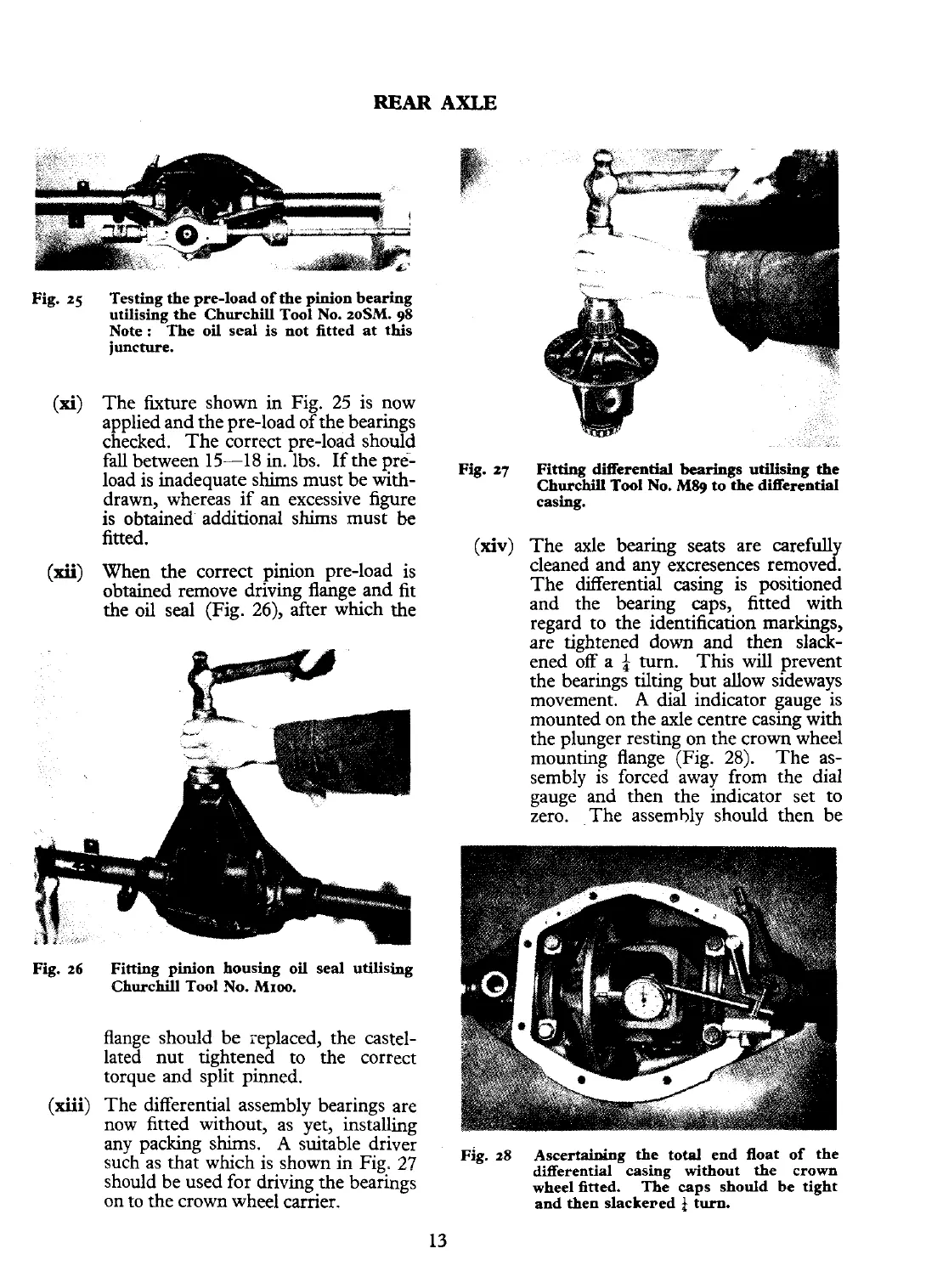

(xiii)

The differential assembly bearings are

now fitted without, as yet, installing

any packing shims.

A

suitable driver

such as that which is shown in Fig.

27

should be used for driving the bearings

on to the crown wheel carrier.

Fig.

27

Fitting Merentid

bearings

utilising the

Churchill

Tool

No.

MSg

to the diierential

casing.

(xiv)

The axle bearing seats are carefully

cleaned and any excresences removed.

The differential casing is positioned

and the bearing caps, fitted with

regard to the identification markings,

are tightened down and then slack-

ened off a

f

turn. This will prevent

the bearings tilting but allow sideways

movement.

A

dial indicator gauge is

mounted on the axle centre cazng\ith

the plunger resting on the crown wheel

mounting flange (Fig.

28).

The as-

sembly is forced away from the dial

gauge and then the indicator set to

zero. The assembly should then be

~i~.

28

Ascertaining the total end float of the

dserential casing without the crown

wheel fitted. The caps should be tight

and then

slacke~ed

$

turn.

Loading...

Loading...