REAR

AXLE

levered in the

opposite

direction until

the taper roller bearings go hard home.

The reading on the

dial

gauge (.062"

for example) will indicate the total

side float of the crown wheel carrier

and should be noted for later reference.

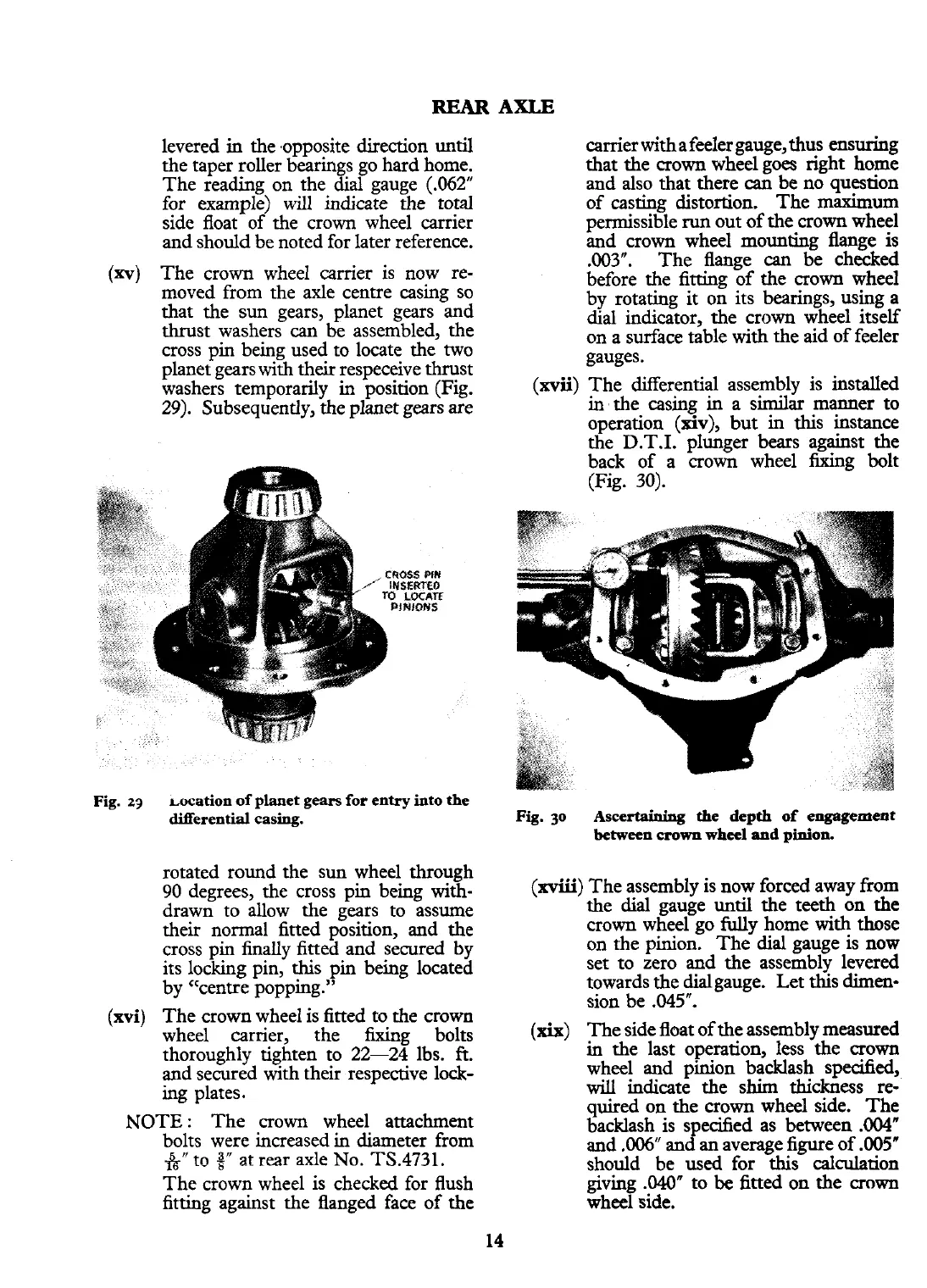

(xv)

The crown wheel carrier is now re-

moved from the axle centre casing so

that the sun gears, planet gears and

thrust washers

can

be assembled, the

cross pin being used to locate the two

planet gears with their respeceive thrust

washers temporarily in position (Fig.

29). Subsequently, the planet gears are

Fig.

29

~ocation

of

planet

gears

for entry into the

differential

casing.

rotated round the sun wheel through

90 degrees, the cross pin being

with-

drawn to allow the gears to assume

their normal fitted position, and the

cross pin finally fitted and secured by

its locking pin, this pin being located

by "centre popping."

(xvi)

The crown wheel is fitted to the crown

wheel carrier, the fixing bolts

thoroughly tighten to 22-24 lbs.

ft.

and secured with their respective lock-

ing plates.

NOTE

:

The crown wheel attachment

bolts were increased in diameter from

h''

to

4''

at

rear axle

No.

TS.4731.

The crown wheel

is

checked for flush

fitting against the flanged face of the

carrier with a feeler

gauge,thus ensuring

that the crown wheel goes right home

and also that there

can

be no question

of casting distortion. The maximum

permissible

run

out of the crown wheel

and crown wheel mounting flange

is

.003". The flange

can

be checked

before the fitting of the crown wheel

by rotating it on its bearings, using a

dial

indicator, the crown wheel itself

on a surface table

with

the aid of feeler

gauges.

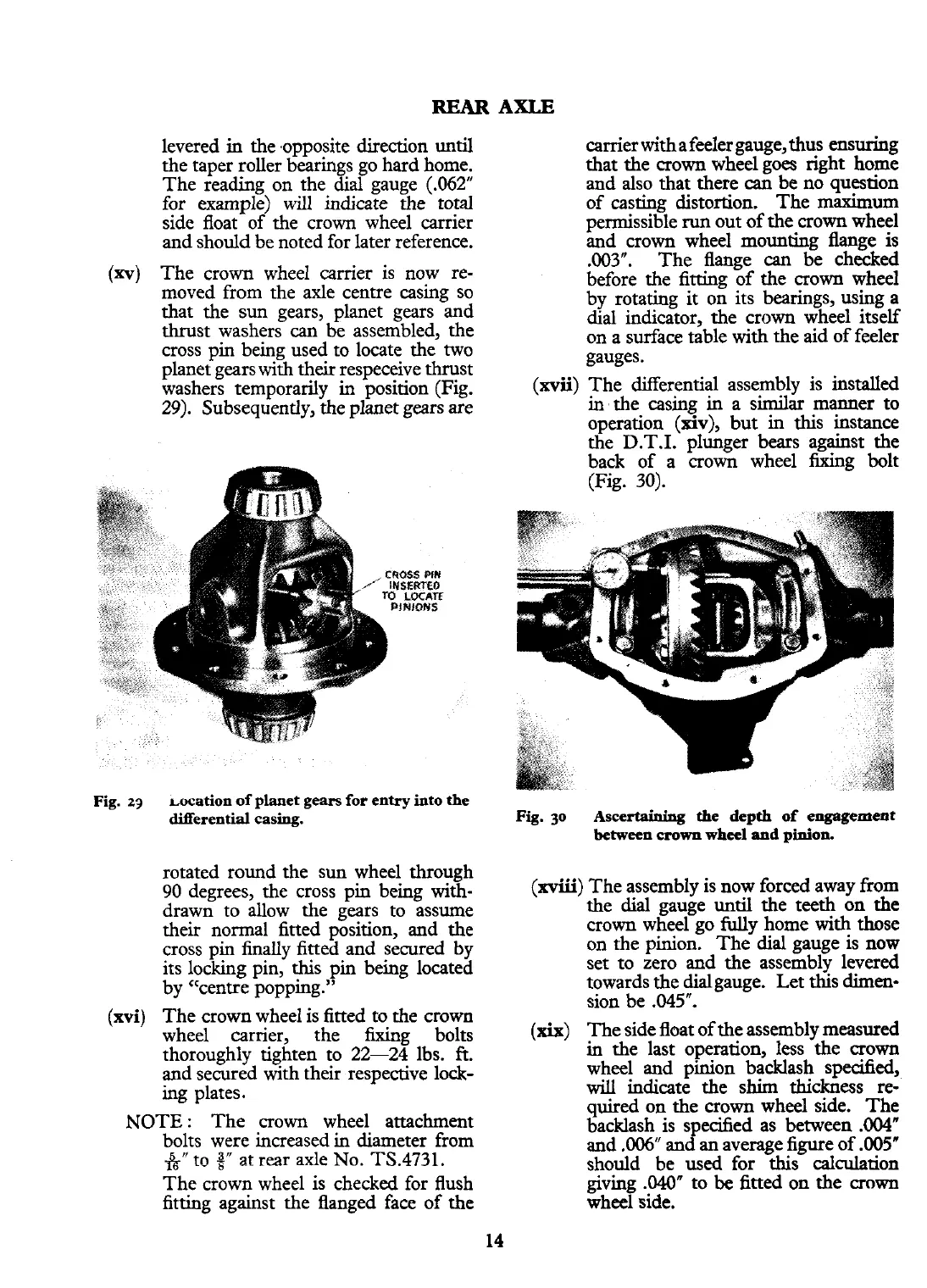

(xvii)

The differential assembly is installed

in'the casing in a similar manner to

operation

(xiv),

but in this instance

the D.T.I. plunger bears against the

back of a crown wheel fixing bolt

(Fig. 30).

Fig.

30

Ascertaining

the depth of

engagement

between

crown

wheel

and

pinion.

(xviii)

The assembly is now forced away from

the dial gauge until the teeth on the

crown wheel go

fully

home with those

on the pinion. The dial gauge is now

set to zero and the assembly levered

towards the dialgauge. Let this

dimen-

sion be

.045".

(xix)

The side float of the assembly measured

in the last operation, less the crown

wheel and pinion backlash specified,

will

indicate the shim thickness re-

quired on the crown wheel side. The

backlash is specified as between

.W"

and .006" and

an

average figure of

.005"

should be used for this calculation

giving

.04OW

to

be

fitted on the crown

wheel side.

Loading...

Loading...