REAR

AXLE

To obtain the thickness of the shims

required between the other differential

bearing and casing, the figure arrived

at in previous operation,

i.e.,

.040",

should be subtracted from the total

side float measured in operation (xiv),

plus an allowance of .005" to provide

the necessary degree of bearing pre-load.

This gives a total shim thickness of

.067" and thus shims on two bearings

will be .040" already estimated and

.067"

-

.040"=.027" on the other side.

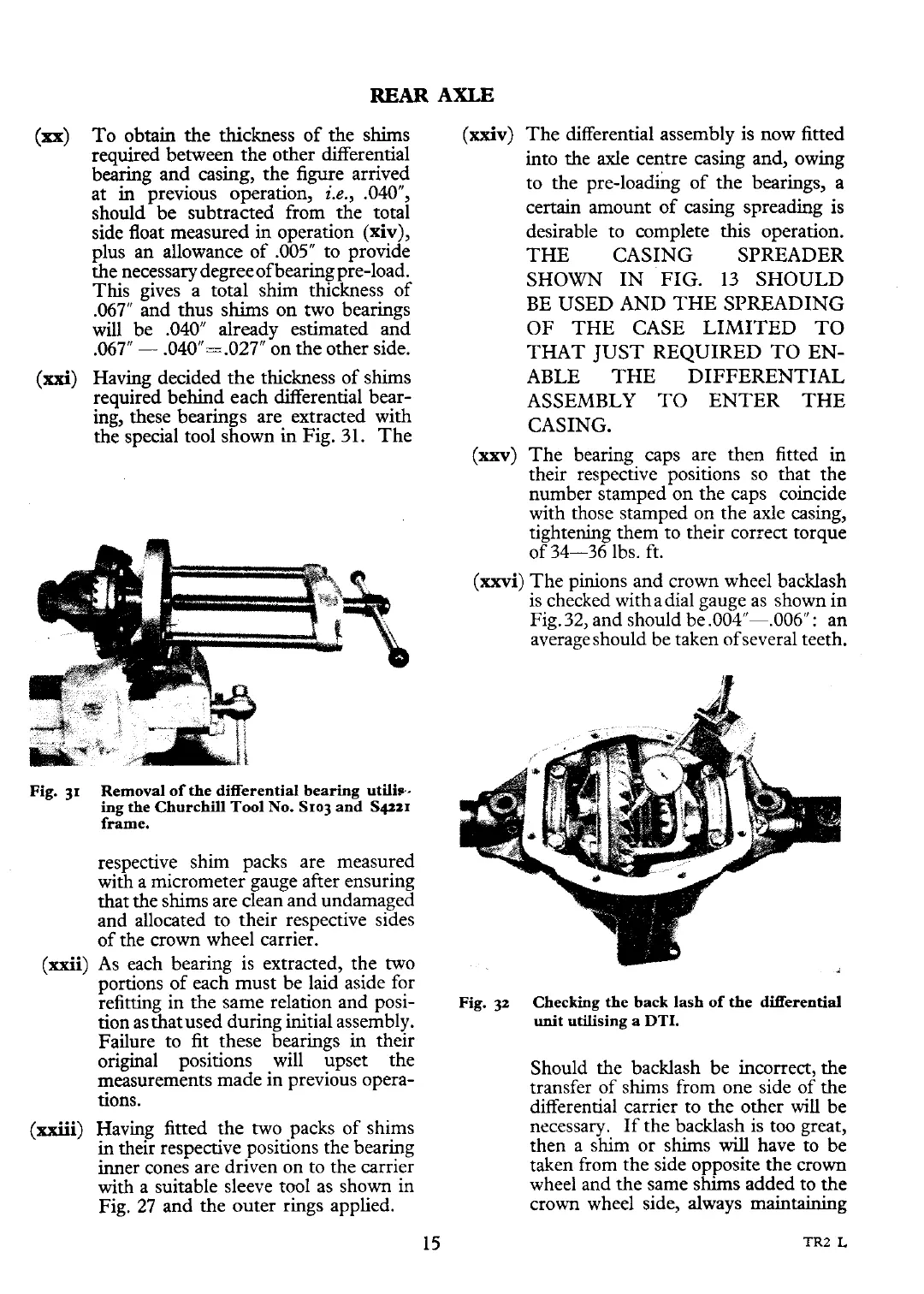

Having decided the thickness of shims

required behind each differential bear-

ing, these bearings are extracted with

the special tool shown

in

Fig.

31.

The

Fig. 31

Removal of the differential bearing utilis-

ing the Churchill Tool No. S103 and

Sqsrr

frame.

respective shim packs are measured

with a micrometer gauge after ensuring

that the shims are clean and undamaged

and allocated to their respective sides

of the crown wheel carrier.

(xxii)

As each bearing is extracted, the two

portions of each must be laid aside for

refitting in the same relation and posi-

tion as thatused during initial assembly.

Failure to

fit

these bearings in their

original positions will upset the

measurements made in previous opera-

tions.

(xxiii)

Having fitted the two packs of shims

in their respective positions the bearing

inner cones are driven on to the carrier

with a suitable sleeve tool as shown in

Fig. 27 and the outer rings applied.

(xxiv) The differential assembly is now fitted

into the axle centre casing and, owing

to the pre-loadi& of the bearings, a

certain amount of casing spreading is

desirable to complete this operation.

THE CASING SPREADER

SHOWN IN FIG.

13

SHOULD

BE USED AND THE SPREADING

OF THE CASE LIMITED TO

THAT JUST REQUIRED TO

EN-

ABLE THE DIFFERENTIAL

ASSEMBLY TO ENTER THE

CASING.

(xxv) The bearing caps are then fitted in

their respective positions so that the

number stamped on the caps coincide

with those stamped on the axle casing,

tightenine them to their correct toraue

ofu34-36ulbs. ft.

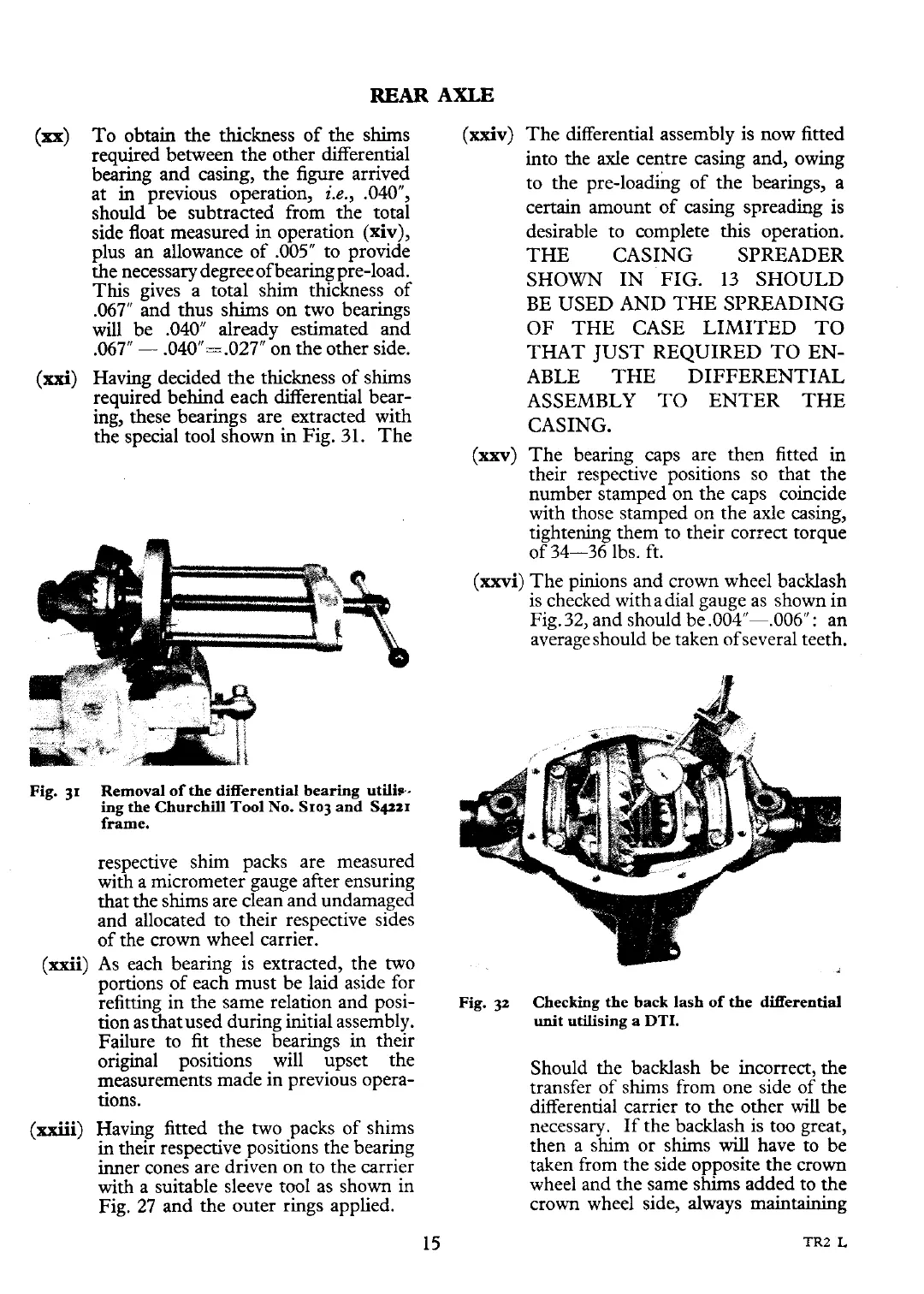

(xxvi) The pinions and crown wheel backlash

is checked withadial gauge as shown in

Fig.

32,

and should be .004"-,006": an

average should be taken ofseveral teeth.

Fig. 32

Checking the back lash of the differential

unit utilising a

DTI.

Should the backlash be incorrect, the

transfer of shims from one side of the

differential carrier to the other will be

necessary.

If

the backlash is too great,

then a shim or shims

will

have to be

taken from the side opposite the crown

wheel and the same shims added to the

crown wheel side, always

maintaining

Loading...

Loading...