REAR

AXLE

the same overall total.Should the back-

lash be insufficient, then the reverse

procedure must be adopted.

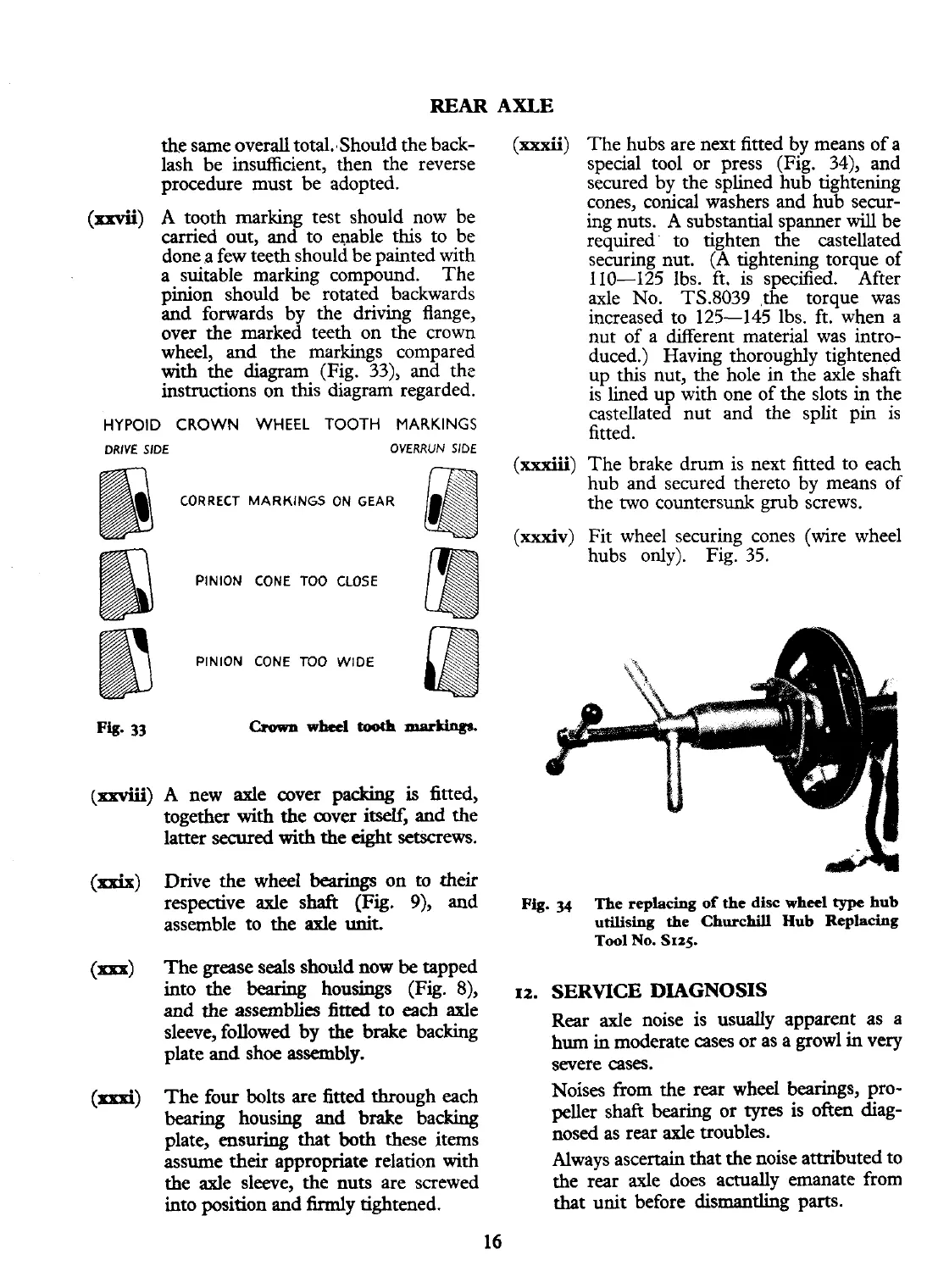

(xxvii)

A

tooth marking test should now be

carried out, and to enable this to be

done a few teeth should be painted with

a suitable marking compound. The

pinion should be rotated backwards

and forwards by the driving flange,

over the marked teeth on the crown

wheel, and the

markings compared

with the diagram (Fig.

33), and the

instructions on this diagram regarded.

HYPOID CROWN WHEEL

TOOTH

MARKINGS

DRIVE

SIDE

OVERRUN SIDE

CORRECT

MARKINGS

ON

GEAR

4

PINION

CONE

TOO

CLOSE

PINION

CONE

TOO

WIDE

(d)

A

new axle cover packing

is

fitted,

together

with

the cover

itself,

and the

latter secured

with

the eight setscrews.

(xxix)

Drive the wheel

bearings

on to their

respective axle shaft

(Fig.

9),

and

assemble to the axle

unit.

(XSX)

The grease seals should now

be

tapped

into the

bearing

housings

(Fig.

8),

and the assemblies

fitted

to each axle

sleeve, followed by the brake backing

plate

and

shoe assembly.

(xxxi)

The four bolts are fitted through each

bearing

housing and brake baclung

plate, ensuring that both these items

assume

their

appropriate relation with

the axle sleeve, the nuts are screwed

into position and firmly tightened.

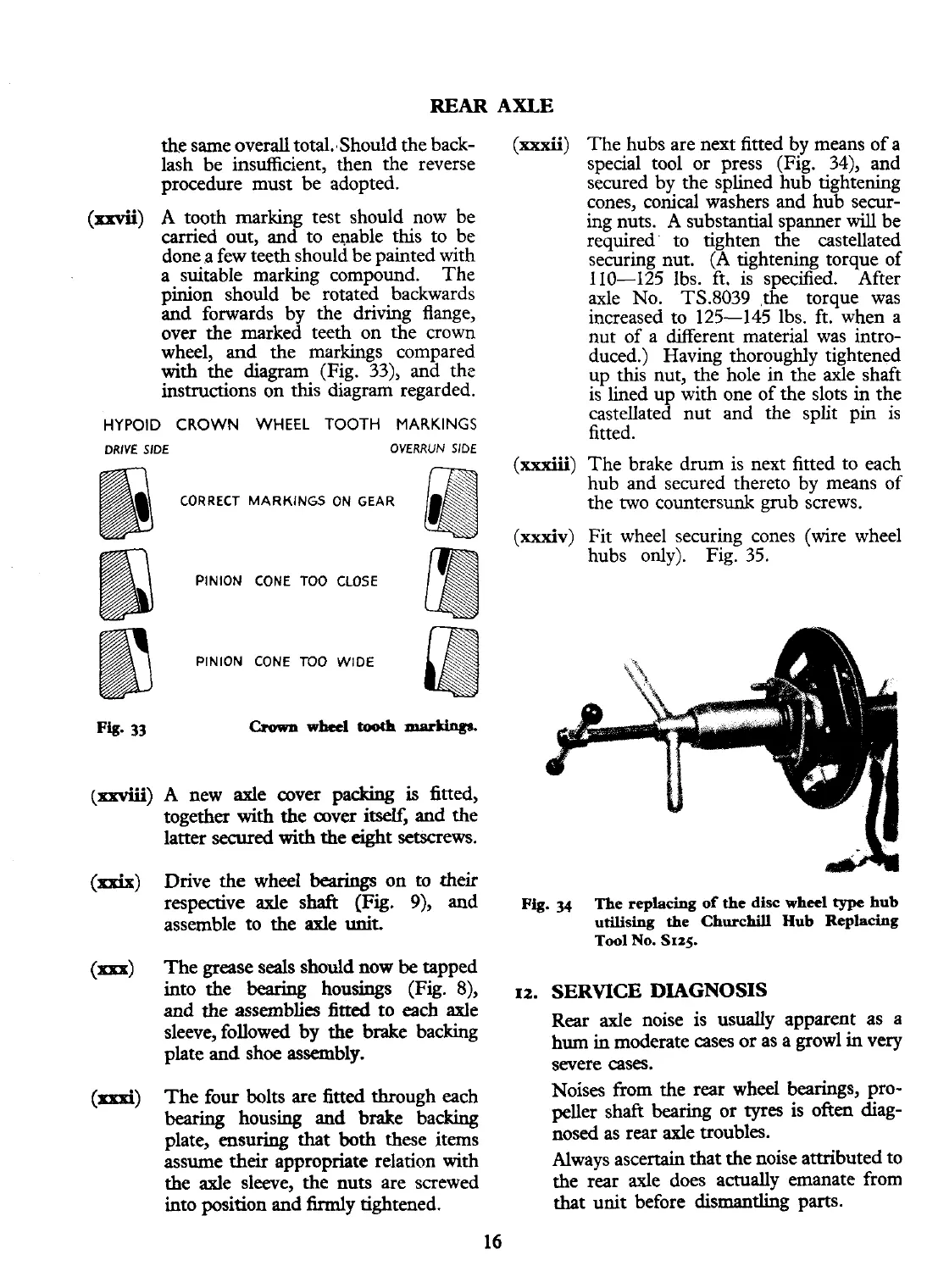

(xxxii)

The hubs are next fitted by means of

a

special tool or press (Fig. 34), and

secured by the splined hub tightening

cones, conical washers and hub secur-

ing nuts. A substantial spanner

will

be

required to tighten the castellated

securing nut. (A tightening torque of

110-125 lbs. ft. is specified. After

axle No. TS.8039 ,the torque was

increased to 125-145 lbs. ft. when a

nut of a different material was intro-

duced.) Having thoroughly tightened

up this nut, the hole in the axle shaft

is lined up with one of the slots in the

castellated nut and the split pin is

fitted.

(xxxiii)

The brake drum is next fitted to each

hub and secured thereto by means of

the two countersunk grub screws.

(xxxiv)

Fit wheel securing cones (wire wheel

hubs only). Fig. 35.

Fig.

34

The replacing

of

the

disc

wheel

type

hub

utilising

the

Churchill

Hub

Replacing

Tool

No.

SIZS.

12.

SERVICE

DIAGNOSIS

Rear

axle noise is usually apparent as a

hum in moderate

cases

or as a growl in very

severe cases.

Noises from the rear wheel bearings, pro-

peller shaft bearing or tyres is often diag-

nosed as rear axle troubles.

Always ascertain that the noise attributed to

the rear axle does actually emanate from

that unit before dismantling parts.

Loading...

Loading...