FRONT SUSPENSION AND STEERING

7.

TO SET STEERING LOCK STOPS

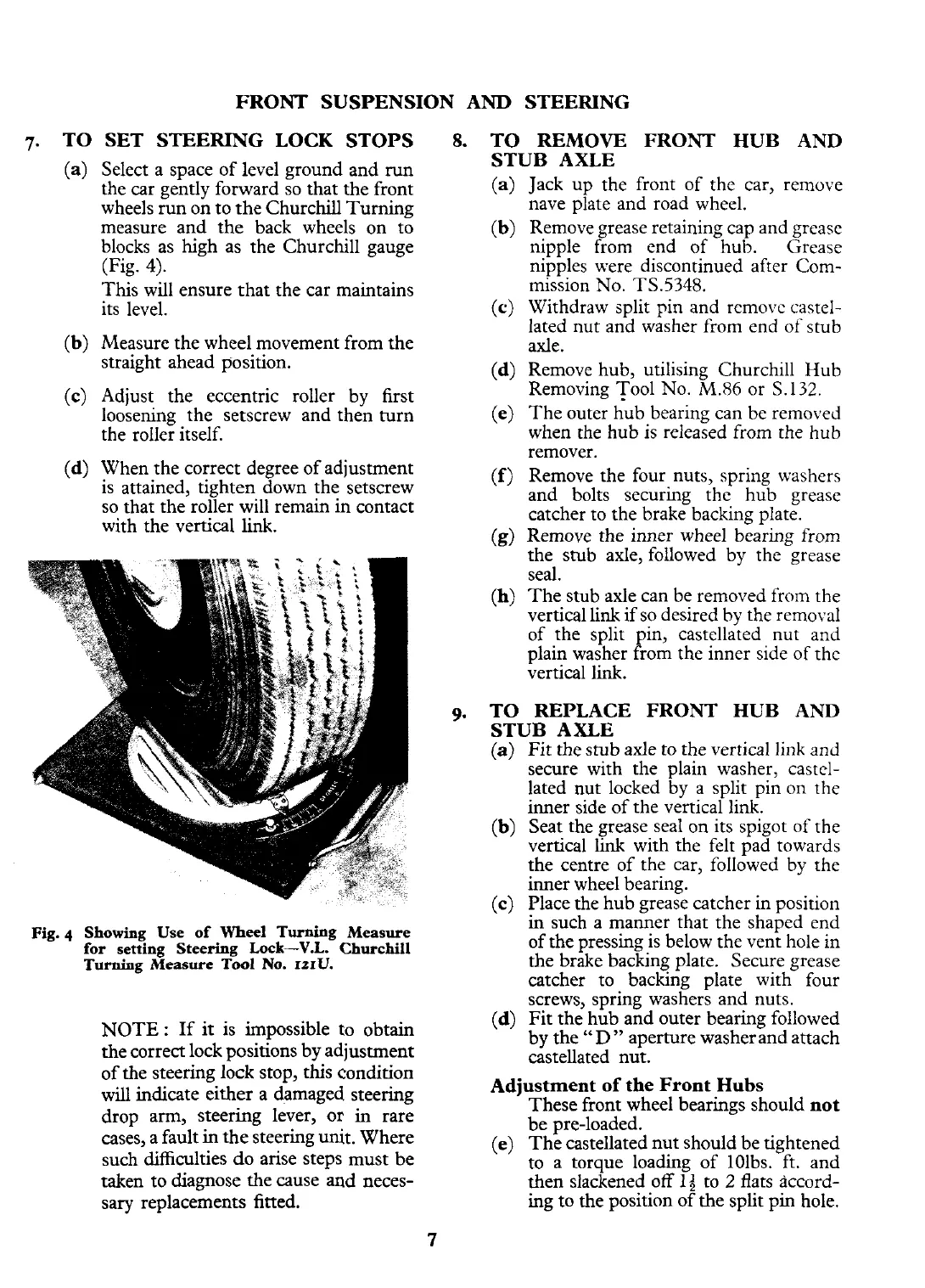

Select a space of level ground and run

the car gently forward so that the front

wheels run on to the Churchill Turning

measure and the back wheels on to

blocks as high as the Churchill gauge

(Fig.

4).

This will ensure that the car maintains

its level.

Measure the wheel movement from the

straight ahead position.

Adjust the eccentric roller by first

loosening the setscrew and then turn

the roller itself.

When the correct degree of adjustment

is attained, tighten down the setscrew

so that the roller will remain in contact

with the vertical

link.

Fig.

4

Showing Use of

Wheel

Turning

Measure

for setting Steering

Lock-V.L. Churchill

Turning

Measure

Tool

No.

IZIU.

NOTE

:

If

it

is impossible to obtain

the correct lock positions by adjustment

of the steering lock stop, this condition

will

indicate either a damaged steering

drop arm, steering lever, or

in

rare

cases, a fault

in

the steering unit. Where

such difficulties do arise steps must be

taken to diagnose the cause and neces-

sary replacements fitted.

8.

TO REMOVE FRONT HUB

AND

STUB AXLE

Jack up the front of the car, remove

nave plate and road wheel.

Remove grease retaining cap and grease

nipple from end of hub. Grease

nipples were discontinued after Com-

mission No.

TS.5348.

Withdraw split pin and removc castel-

lated nut and washer from end of stub

axle.

Remove hub, utilising Churchill Hub

Removing Tool No. M.86 or S. 132.

The outer hub bearing can be removed

when the hub is released from the hub

remover.

Remove the four nuts, spring washers

and bolts securing the hub grease

catcher to the brake backing plate.

Remove the inner wheel bearing from

the stub axle, followed by the grease

seal.

The stub axle can be removed from the

vertical link if so desired by the removal

of the split pin, castellated nut and

plain washer from the inner side of

the

vertical link.

9.

TO REPLACE FRONT HUB

AND

STUB AXLE

(a)

Fit the stub axle to the vertical link and

secure with the plain washer, castel-

lated nut locked by a split pin on the

inner side of the vertical link.

(b) Seat the grease seal on its spigot of the

vertical

link

with the felt pad towards

the centre of the car, followed by the

inner wheel bearing.

(c) Place the hub grease catcher in position

in such a manner that the shaped end

of the pressing is below the vent hole in

the brake backing plate. Secure grease

catcher to backing plate with four

screws, spring washers and nuts.

(d)

Fit the hub and outer bearing followed

by the

"D"

aperture washerand attach

castellated nut.

Adjustment of the Front

Hubs

These front wheel bearings should

not

be pre-loaded.

(e)

The castellated nut should be tightened

to a torque loading of 10lbs. ft. and

then slackened off

14

to

2

flats accord-

ing to the position of the split pin hole.

Loading...

Loading...