FRONT SUSPENSION

AND

STEERING

Feed the locking washer and steering

lock stop bush on to the steering stop

securing bolt and attach to the bottom

trunnion assembly. The bolt is left

finger tight at this juncture.

Fit two rubber bushes to the inner

lower

fulcrum

pin situated on the

upper face of the chassis frame, one

to each side.

Fit two thrust washers to the shackle

pin, one to each side, followed by the

grease seal.

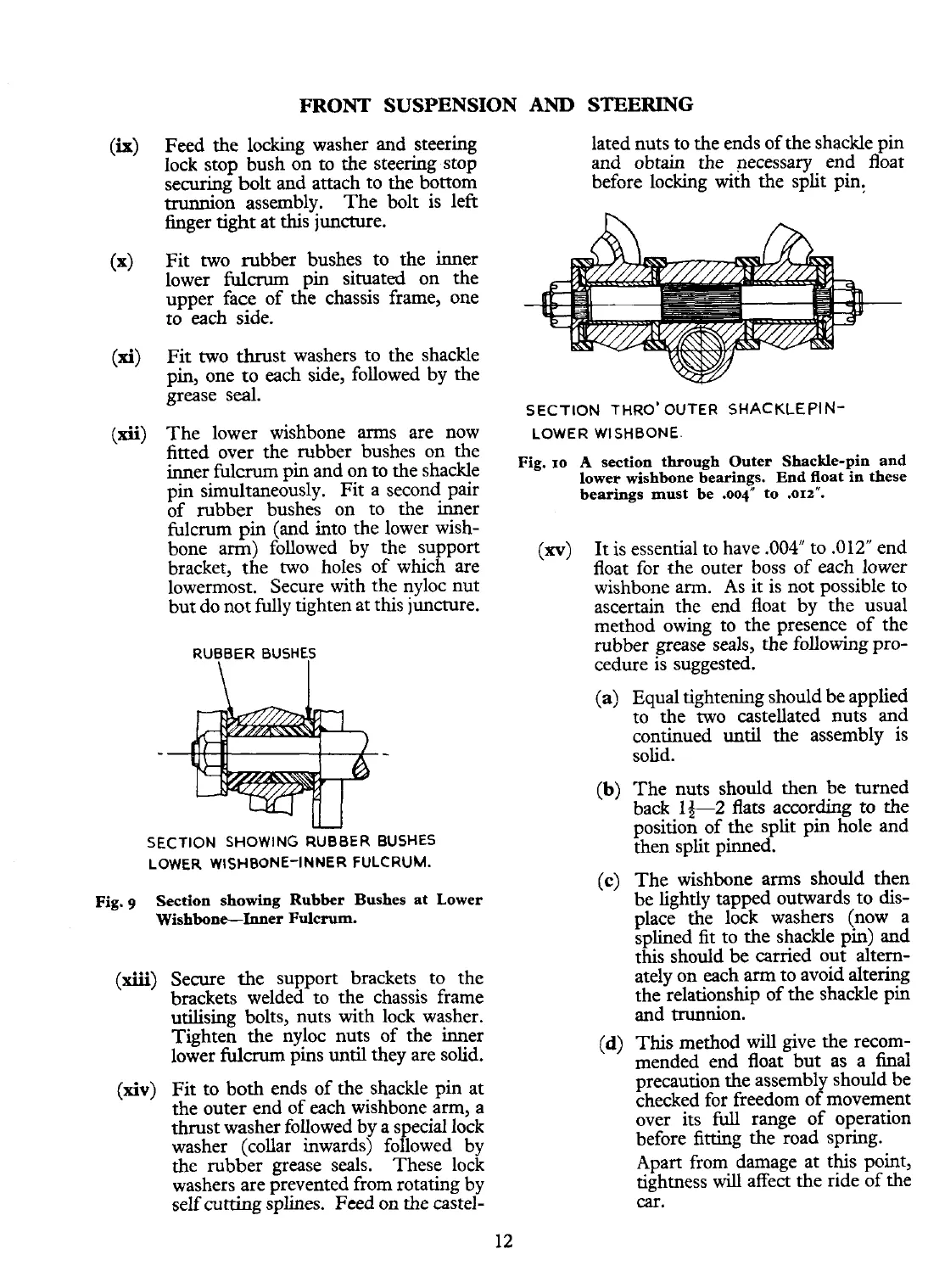

The lower wishbone arms are now

fitted over the rubber bushes on the

inner fulcrum pin and on to the shackle

pin simultaneously. Fit a second pair

of rubber bushes on to the inner

fulcrum pin (and into the lower wish-

bone arm) followed by the support

bracket, the two holes of which are

lowermost. Secure with the nyloc nut

but do not fully tighten at this juncture.

RUBBER

BUSHES

SECTION SHOWING

RUBBER

BUSHES

LOWER WISHBONE-INNER

FULCRUM.

Fig.

9

Section showing Rubber Bushes at Lower

Wishbone--Inner Fulcrum.

(xiii)

Secure the support brackets to the

brackets welded to the chassis frame

utilising bolts, nuts with lock washer.

Tighten the nyloc nuts of the inner

lower fulcrum pins until they are solid.

(xiv)

Fit to both ends of the shackle pin at

the outer end of each wishbone arm, a

thrust washer followed by a special lock

washer (collar inwards) followed by

the rubber grease seals. These lock

washers are prevented from rotating by

self cutting splines. Feed on the castel-

lated nuts to the ends of the shackle pin

and obtain the necessary end float

before

locking with the split pin,

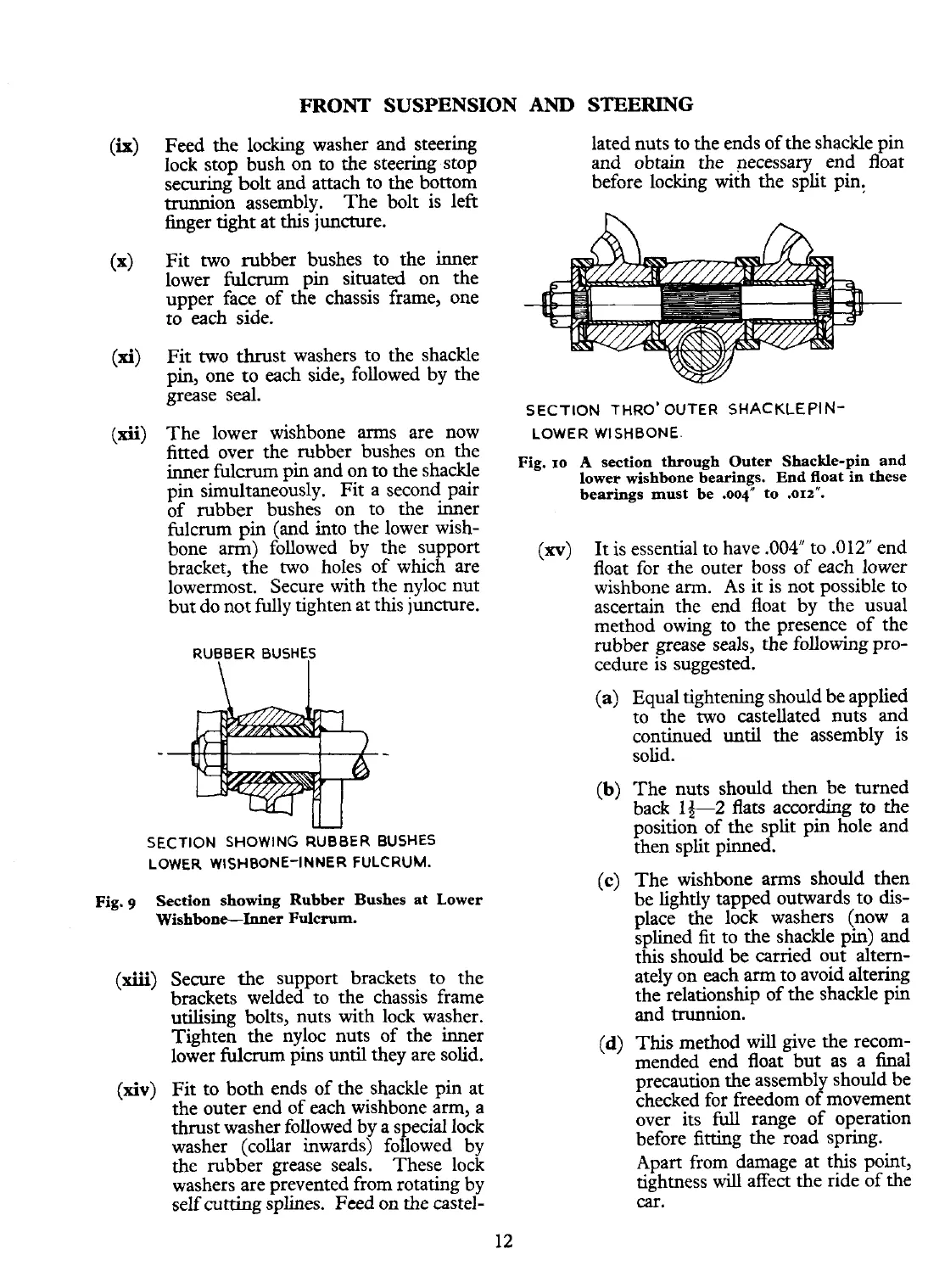

SECTION

THRO'OUTER

SHACKLEPIN-

LOWER WISHBONE.

Fig.

10

A

section through Outer Shackle-pin and

lower wishbone bearings. End float in these

bearings must be

.004" to .OIZ".

(m)

It

is essential to have

.004"

to

.012"

end

float for the outer boss of each lower

wishbone arm. As it is not possible to

ascertain the end float by the usual

method owing to the presence of the

rubber grease seals, the following pro-

cedure is suggested.

(a)

Equal tightening should be applied

to the two castellated nuts and

continued until the assembly is

solid.

(b)

The nuts should then be turned

back 1+2 flats according to the

positioG of the split pin

gale

and

then split pinned.

(c)

The wishbone arms should then

be lightly tapped outwards to dis-

place the lock washers (now a

splined

fit

to the shackle pin) and

this should be carried out altern-

ately on each arm to avoid altering

the relationship of the shackle pin

and trunnion.

(d)

This method

will

give the recom-

mended end float but as a final

precaution the assembly should be

checked for freedom of movement

over its

full

range of operation

before fitting the road spring.

Apart from damage at this point,

tightness

will

affect the ride of the

car.

Loading...

Loading...