FRONT SUSPENSION

AND

STEERING

Withdraw the split pin from the castel-

lated nut securing the ball joint as-

sembly to the upper wishbone arm.

Remove the castellated nut and with-

draw the ball joint assembly from the

wishbone arms, collecting the distance

piece as the ball joint is moved.

Withdraw the split pin and remove the

nut and plain washer securing the ball

joint assembly to the vertical

link

and

withdraw ball joint.

Withdraw the split pins from the

castellated nuts at the outer ends of the

upper inner

fulcrum pin. Remove the

large diameter plain washers and the

outer rubber bushes.

The wishbone arms

can

now be re-

moved and the second rubber bush

withdrawn from the fulcrum pin.

Remove the steering stop screw from

the lower end of the vertical

link

and

detach the bottom trunnion assembly

from the vertical

link

and collect the oil

seal situated between the vertical

link

and the trunnion assembly.

TO

ASSElMBLE

AND

REPLACE

FRONT SUSPENSION

UNIT

Assembly is made with strict regard to the

markings on certain parts to ensure that

they are returned to the same relative

position.

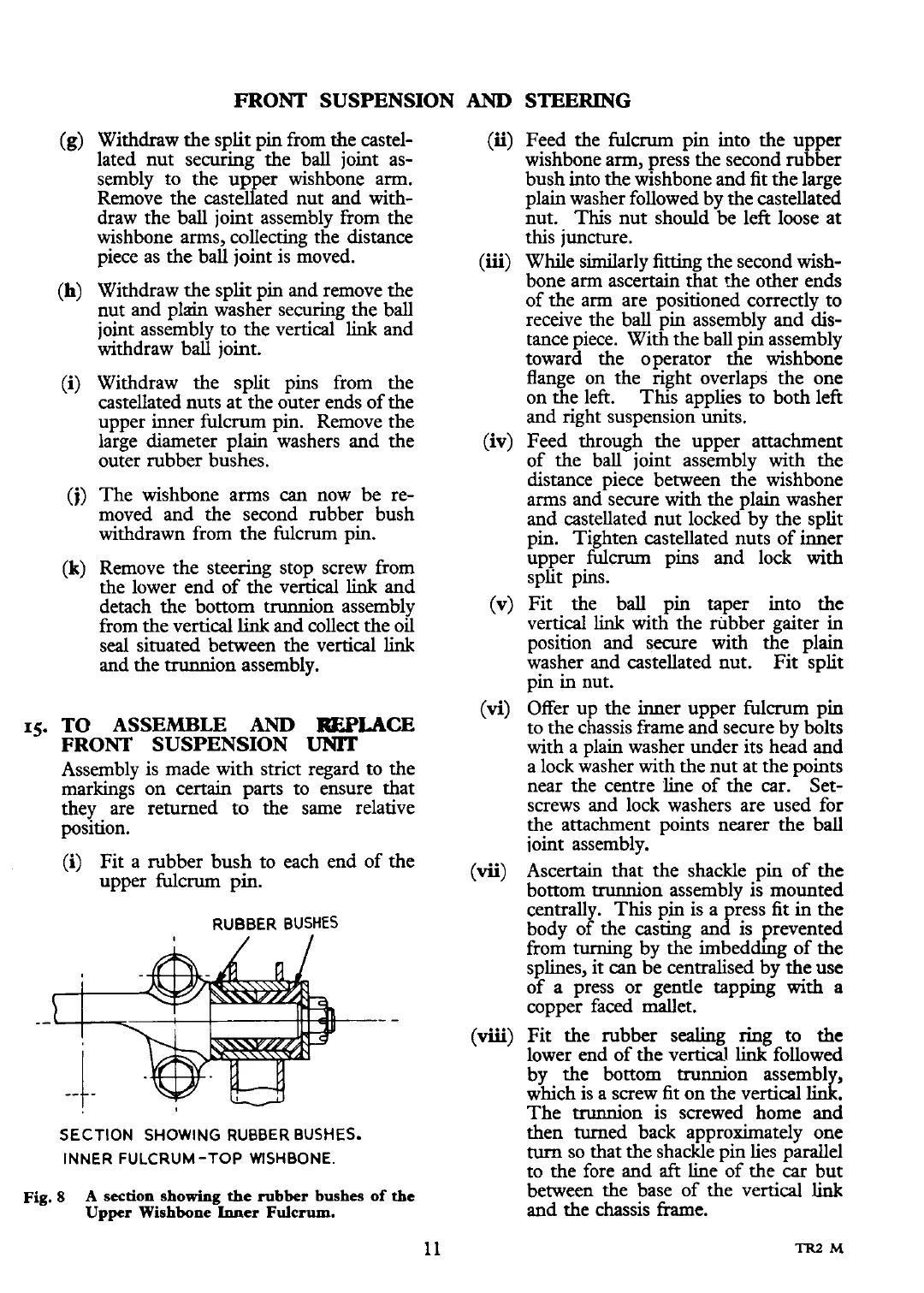

(i)

Fit a rubber bush to each end of the

upper fulcrum pin.

RUBBER BUSHES

(ii)

Feed the fulcrum pin into the upper

wishbone arm, press the second rubber

bush into the wishbone and fit the large

plain washer followed by the castellated

nut. This nut should be left loose at

this juncture.

(iii)

While similarly fitting the second wish-

bone arm ascertain that the other ends

of the arm are positioned correctly to

receive the ball pin assembly and dis-

tance piece. With the ball pin assembly

toward the operator the wishbone

flange on the right overlaps the one

on the left. This applies to both left

and right suspension units.

(iv)

Feed through the upper attachment

of the ball joint assembly with the

distance piece between the wishbone

arms and secure with the plain washer

and castellated nut locked by the split

pin. Tighten castellated nuts of inner

upper fulcrum pins and lock with

split pins.

(v)

Fit the ball pin taper into the

vertical

link

with the rubber gaiter in

position and secure with the plain

washer and castellated nut. Fit split

pin in nut.

(vi)

Offer up the inner upper fulcrum pin

to the chassis frame and secure by bolts

with a plain washer under its head and

a lock washer with the nut at the points

near the centre line of the car. Set-

screws and lock washers are used for

the attachment points nearer the ball

ioint assembly.

(vii)

Ascertain that the shackle pin of the

bottom trunnion assembly is mounted

centrally. This pin is a

ress

fit

in

the

body of the casting an

B

is prevented

from turning by th; imbeddhg of the

splines, it

can

be centralised by the use

of a press or gentle tapping

with

a

copper faced mallet.

(viii)

Fit the rubber sealing ring to the

lower end of the vertical

link

followed

by the bottom trunnion assembl

which is a screw fit on the vertical

d

The trunnion is screwed home and

SECTION SHOWING RUBBER BUSHES.

then turned back approximately one

INNER FULCRUM-TOP WISHBONE.

turn

SO

that the shackle pin lies parallel

to the fore and

aft

line of the car but

Fig.

8

A

section showing

the

rubber bushes of the

between the base of the vertical

link

Upper Wishbone Inner

Fulcrum.

and the chassis frame.

Loading...

Loading...