FRONT SUSPENSION

AND

STEERING

The drop arm must only be removed by a

special puller, Tool No. M.91 is re-

commended, a hammer must not be used

since any blow would be transferred to the

hardened conical pin in the rocker shaft

lever which would

in

turn

indent the cam

gear and damage the unit.

The drop arm should only be replaced when

the trunnion bracket is in position on the

rocker shaft housing. The arm is set in such

a manner that it will

ooint rearwards and

downwards and the scribe line on the end of

the rocker shaft will align with that on the

drop arm and appear to be continuous.

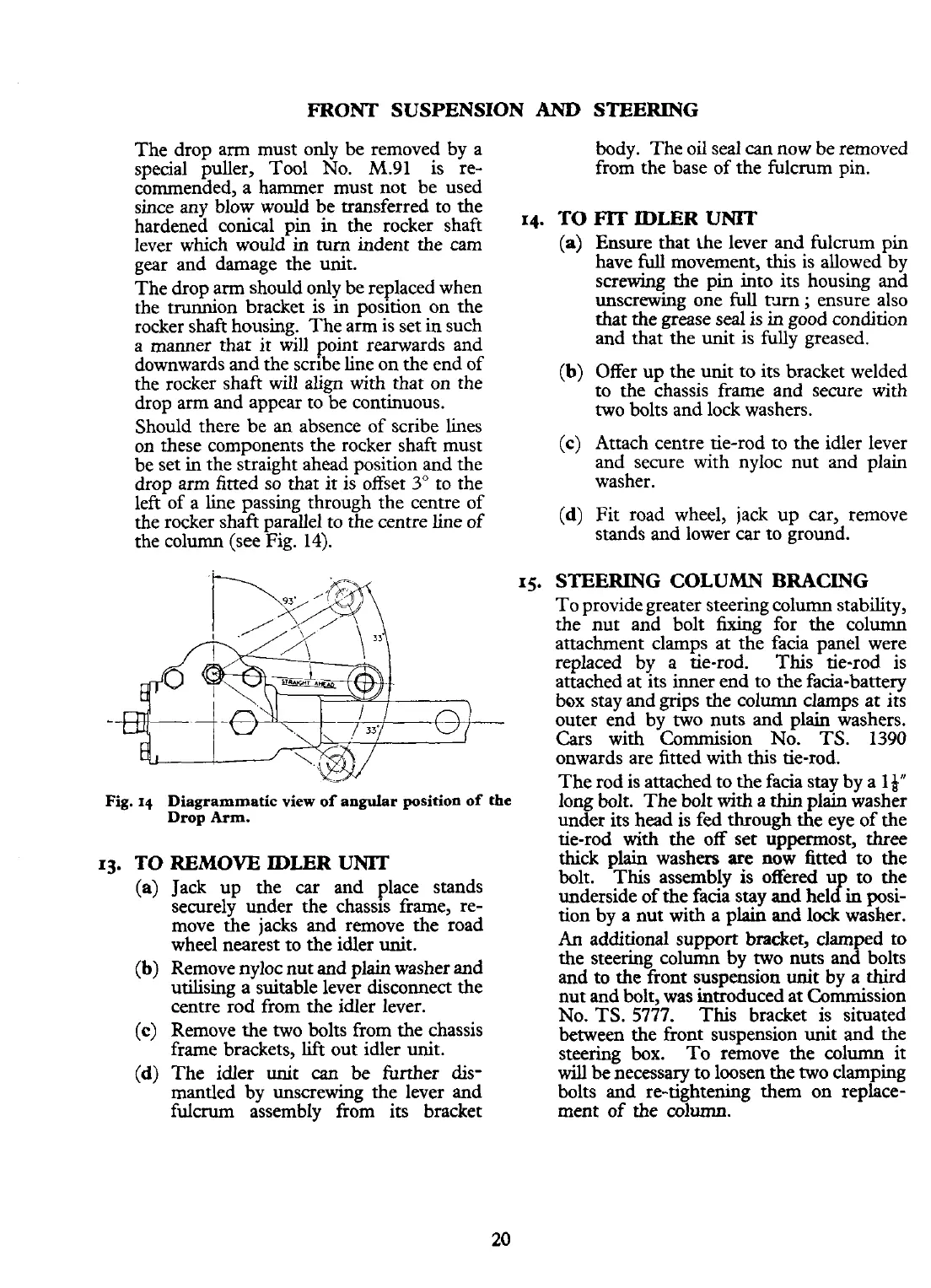

Should there be an absence of scribe lines

on these components the rocker shaft must

be set in the straight ahead position and the

drop arm fitted so that it is offset

3"

to the

left of a line passing through the centre of

the rocker

shaft parallel to the centre line of

the column (see Fig. 14).

body. The oil seal

can

now be removed

from the base of the fulcrum pin.

14.

TO

FIT

IDLER

UNIT

(a) Ensure that he lever and fulcrum pin

have

full

movement, this is allowed by

screwing the pin into its housing and

unscrewing one

full

mm

;

ensure also

that the grease seal is in good condition

and that the unit is fully greased.

(b)

Offer up the unit to its bracket welded

to the chassis frame and secure with

two bolts and lock washers.

(c)

Attach centre tie-rod to the idler lever

and secure with nyloc nut and plain

washer.

(d)

Fit road wheel, jack up car, remove

stands and lower car to ground.

15.

STEERING COLUMN BRACING

To provide greater steering column stability,

the nut and bolt fixing for the column

attachment clamps at the facia panel were

replaced by a tie-rod. This tie-rod is

attached at its inner end to the facia-battery

box stay and grips the column clamps at its

outer end by two nuts and plain washers.

Cars with

Commision No. TS. 1390

onwards are fitted with this tie-rod.

The rod is attached to the facia stay by a

14"

Fig.

14

Diagrammatic

view

of

angular

position

of

the

long bolt. The bolt with a

thin

plain washer

Drop

Arm.

under its head is fed through the eye of the

tie-rod

with

the off set u~~ermost,

three

TO

REMOVE IDLER

UNIT

(a) Jack up the car and place stands

securely under the chassis frame, re-

move the jacks and remove the road

wheel nearest to the idler unit.

(b)

Remove nyloc nut and plain washer and

utilising a suitable lever disconnect the

centre rod from the idler lever.

(c)

Remove the two bolts from the chassis

frame brackets,

lift

out idler unit.

(d)

The idler unit

can

be further dis-

mantled by unscrewing the lever and

fulcrum assembly from its bracket

thick

plain

washers are

n&

fitted-to the

bolt. This assembly

is

offered u to the

underside of the facia stay and helfin posi-

tion by a nut with a plain and

lock

washer.

An

additional support bracket, clamped to

the steering column by two nuts and bolts

and to the front suspension unit

by

a third

nut and bolt,

was

introduced at Commission

No.

TS.

5777.

This bracket is situated

between the front suspension unit and the

steering box. To remove the column it

will

be necessary to loosen the two clamping

bolts and re-tightening them on replace-

ment of

the

column.

Loading...

Loading...