ROAD SPRINGS

AND

SHOCK ABSORBERS

The unit is filled to the base of the Mer plug

boss which prevents over filling and main-

tains the necessary air space essential to

satisfactory operation. The working mech-

anism is completely submerged in oil which

is prevented from leaking along the spindle

by means of oil seals.

The damper requires very little attention

but the fluid level should be checked every

15,000

miles.

It

should be topped up to the

lower reaches of the filler boss and only with

Armstrong Shock Absorber Oil No.

624

should be used, the guarantee of this partic-

ular component becomes void if any other

oil is used.

Every precaution must be taken to ensure

that no lubrication is given to the rubber

mountings of the connecting

link.

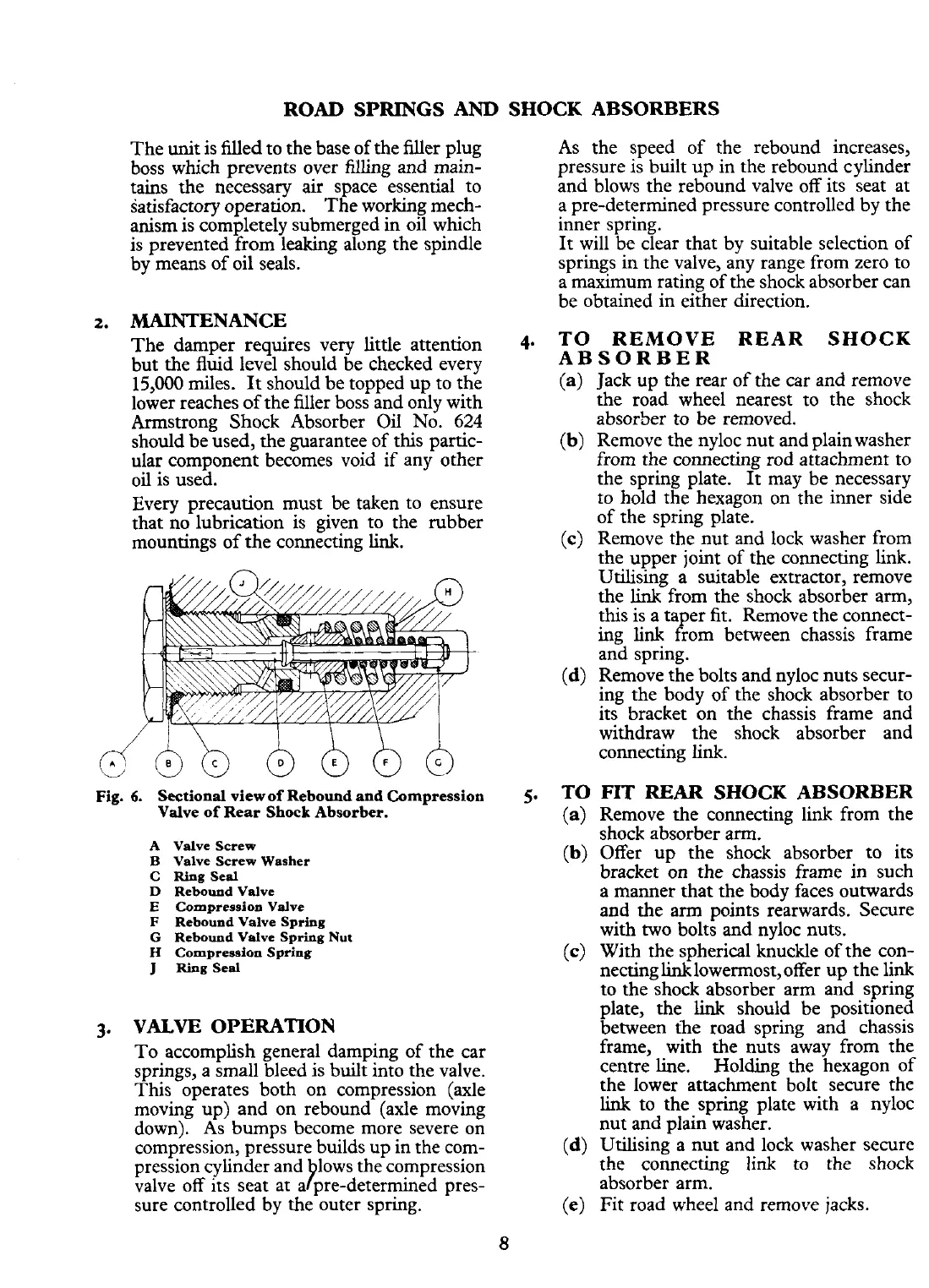

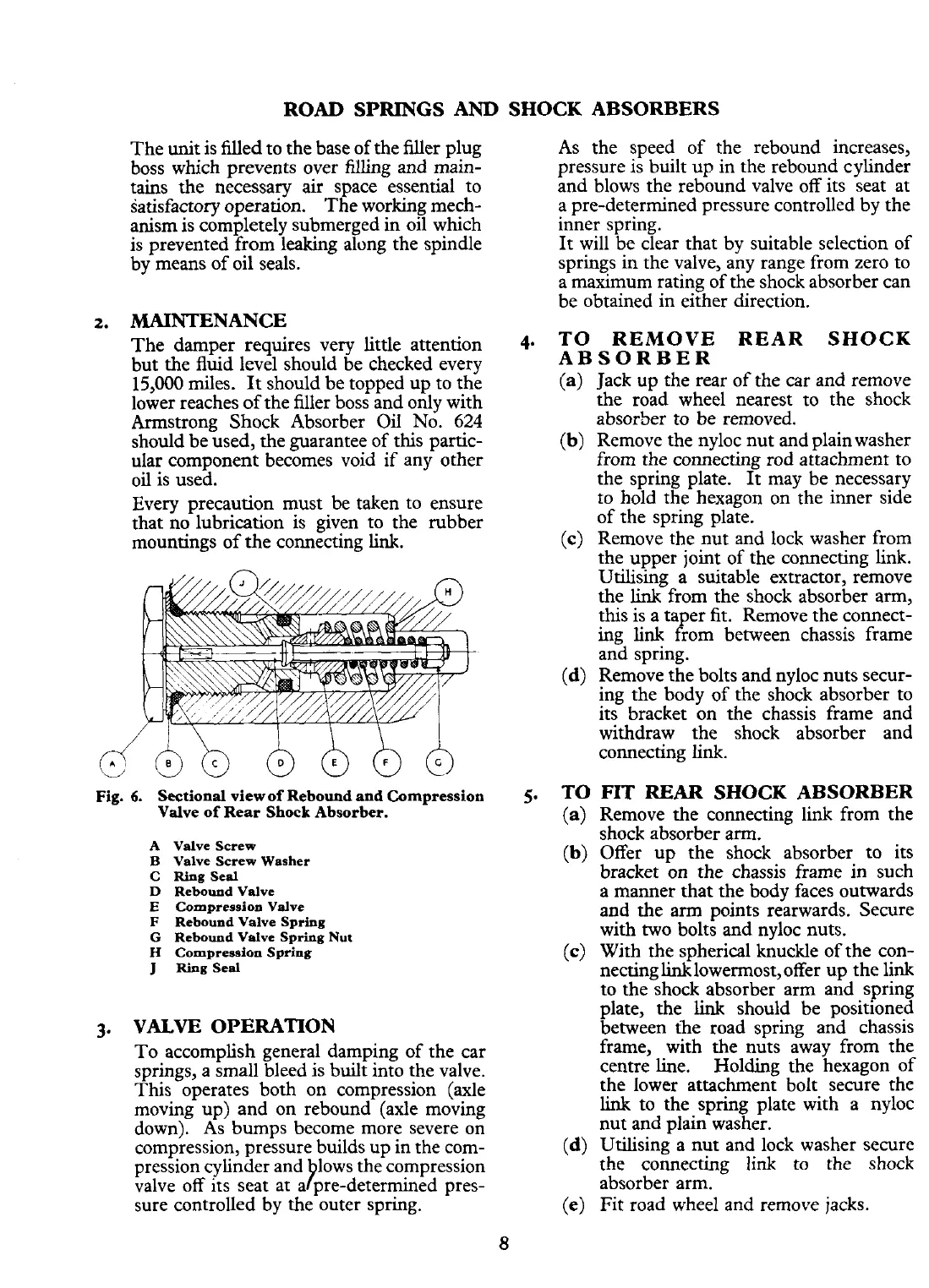

Fig.

6.

Sectional viewof Rebound and Compression

Valve of Rear Shock Absorber.

A

Valve Screw

B

Valve Screw Washer

C Ring Seal

D

Rebound Valve

E

Compression Valve

F

Rebound Valve Spring

G

Rebound Valve Spring

Nut

H

Compression Spring

J

Ring Seal

3.

VALVE OPERATION

To accomplish general damping of the car

springs, a small bleed is built into the valve.

This operates both on compression (axle

moving up) and on rebound (axle moving

down). As bumps become more severe on

compression, pressure builds up in the com-

pression cylinder and lows the compression

P

valve off its seat at a pre-determined pres-

sure controlled by the outer spring.

As the speed of the rebound increases,

pressure is built up in the rebound cylinder

and blows the rebound valve off its seat at

a pre-determined pressure controlled by the

inner spring.

It will be clear that by suitable selection of

springs in the valve, any range from zero to

a maximum rating of the shock absorber can

be obtained in either direction.

4.

TO REMOVE REAR SHOCK

ABSORBER

(a) Jack up the rear of the car and remove

the road wheel nearest to the shock

absorber to be removed.

(b)

Remove the nyloc nut and plain washer

from the connecting rod attachment to

the spring plate.

It

may be necessary

to hold the hexagon on the inner side

of the spring plate.

(c) Remove the nut and lock washer from

the upper joint of the connecting link.

Utilising a suitable extractor, remove

the

link

from the shock absorber arm,

this is a taper

fit.

Remove the connect-

ing link from between chassis frame

and spring.

(d) Remove the bolts and nyloc nuts secur-

ing the body of the shock absorber to

its bracket on the chassis frame and

withdraw the shock absorber and

connecting link.

5.

TO

FIT

REAR

SHOCK ABSORBER

(a) Remove the connecting link from the

shock absorber arm.

(b)

Offer up the shock absorber to its

bracket on the chassis frame in such

a manner that the body faces outwards

and the arm points rearwards. Secure

with two bolts and nyloc nuts.

(c) With the spherical knuckle of the con-

necting linklowermost, offer up the link

to the shock absorber arm and spring

plate, the

link

should be positioned

between the road spring and chassis

frame, with the nuts away from the

centre line. Holding the hexagon of

the lower attachment bolt secure the

link

to the spring plate with a nyloc

nut and plain washer.

(d) Utilising a nut and lock washer secure

the connecting

link

to the shock

absorber arm.

(e)

Fit road wheel and remove jacks.

Loading...

Loading...