PROPELLER

SHAFT

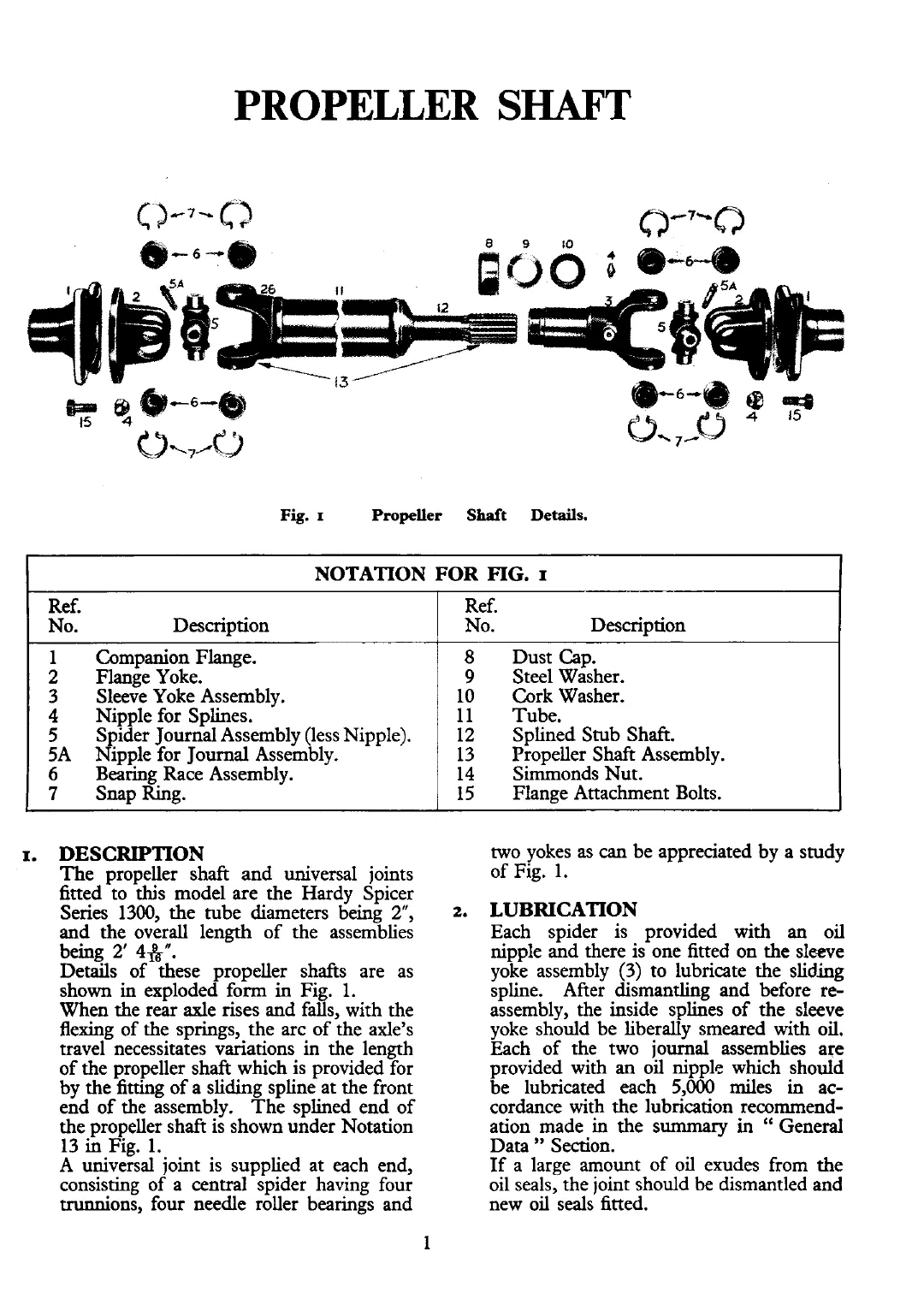

Fig.

I

Propeller

Shaft

Details.

Companion Flange.

Flange Yoke.

Sleeve Yoke Assembly.

Nipple for Splines.

Spider Journal Assembly (less Nipple).

Nipple for Journal Assembly.

Bearing Race Assembly.

Snav Ring.

NOTATION FOR

FIG.

I

Dust Cap.

Steel Washer.

Cork Washer.

Tube.

Splined Stub Shaft.

Propeller Shaft Assembly.

Simmonds Nut.

Flange Attachment Bolts.

Ref.

No. Description

I.

DESCRIPTION

The propeller shaft and universal joints

fitted to this model are the Hardy Spicer

Series 1300, the tube diameters being

2",

2-

and the overall length of the assemblies

Ref.

No. Description

-

being

2'

4fk".

Details of these ~ro~eller shafts are as

shown in exploded fgm in Fig.

1.

When the rear axle rises and falls, with the

flexing of the springs, the arc of the axle's

travel necessitates variations in the length

of the propeller shaft which is provided for

by the fitting of a sliding spline at the front

end of the assembly. The splined end of

the

vroveller shaft is shown under Notation

13

&

~i~.

l.

A universal joint is supplied at each end,

consistina of a central svider havine four

trunnion; four needle roller bearinis and

two yokes as

can

be appreciated by a study

of Fig. 1.

LUBRICATION

Each spider is provided with an oil

nipple and there is one fitted on the sleeve

yoke assembly (3) to lubricate the sliding

spline. After dismantling and before

re-

assembly, the inside splines of the sleeve

yoke should be liberally smeared with oil.

Each of the two journal assemblies are

provided with an oil nipple which should

be lubricated each 5,000 miles in ac-

cordance with the lubrication

recornmend-

ation made in the summary in

"

General

Data

"

Section.

If a large amount of oil exudes from the

oil seals, the joint should be dismantled and

new oil seals fitted.

Loading...

Loading...