PROPELLER

SHAFT

3.

MAINTENANCE INSTRUCTIONS

To

test

for

wear

Wear on the thrust faces is located by

testing the

lift

in the joint by hand.

Any circumferential movement of the shaft

relative to the flange yokes indicates wear

in the needle roller bearings and/or the

sliding splines.

+

REMOVAL

OF

PROPELLER

SHAFT

(a)

Jack

up one rear wheel clear of the

ground to enable the propeller shaft

to

be

rotated.

(b)

Remove nuts from bolts at both flange

yokes engaging ht gear, as necessary

to hold the shaft from turning when

slackening nuts.

(c)

Tap out bolts and remove propeller

shaft assembly.

5.

TO

DISMANTLE PROPELLER

sm

Before commencing to dismantle propeller

shaft see

if

"

arrow" location marks are

visible when the parts are clean. If no

marlungs are visible, re-mark to ensure

correct

re-assembly.

Having unscrewed the dust cap

(8,

Fig.

l),

pull sleeve yoke assembly

(3,

Fig.

1)

off

shaft.

Clean

enamel from snap rings and

top of bearings races. Remove

all

snap

rings by pinching ears together with

a

suitable pair of circlip pliers and sub-

sequently prising out these with

a

screw-

driver. If ring does not snap out of groove

readily, tap end of bearing race lightly in-

wards to relieve the ressure against ring.

Holding joint in le

f!

hand with splined

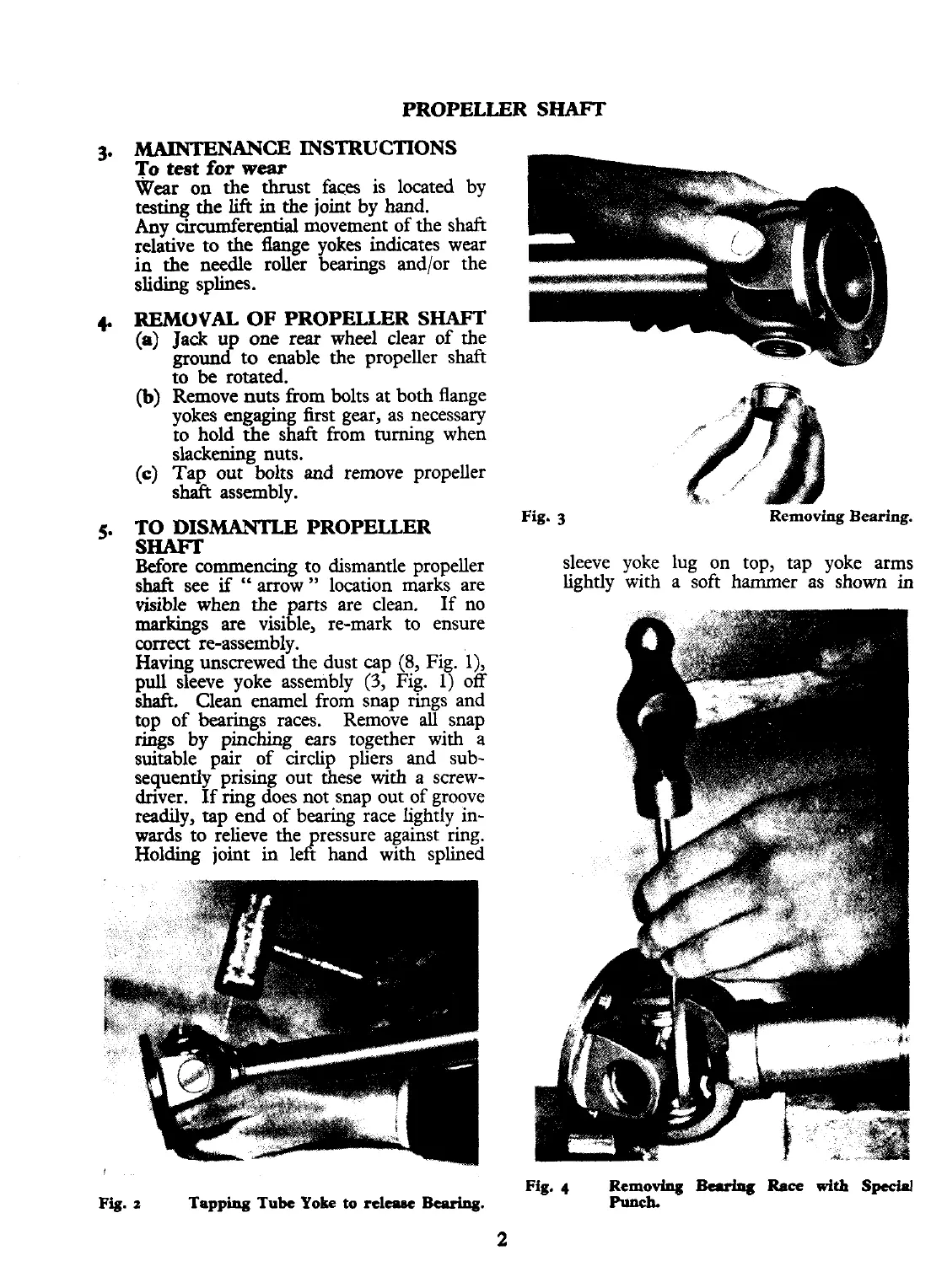

Fig.

3

Removing Bearing.

sleeve yoke lug on top, tap yoke arms

lightly with

a

soft hammer as shown

in

Fig.

2

Tapping

Tube

Yoke

to

relame

Bearing.

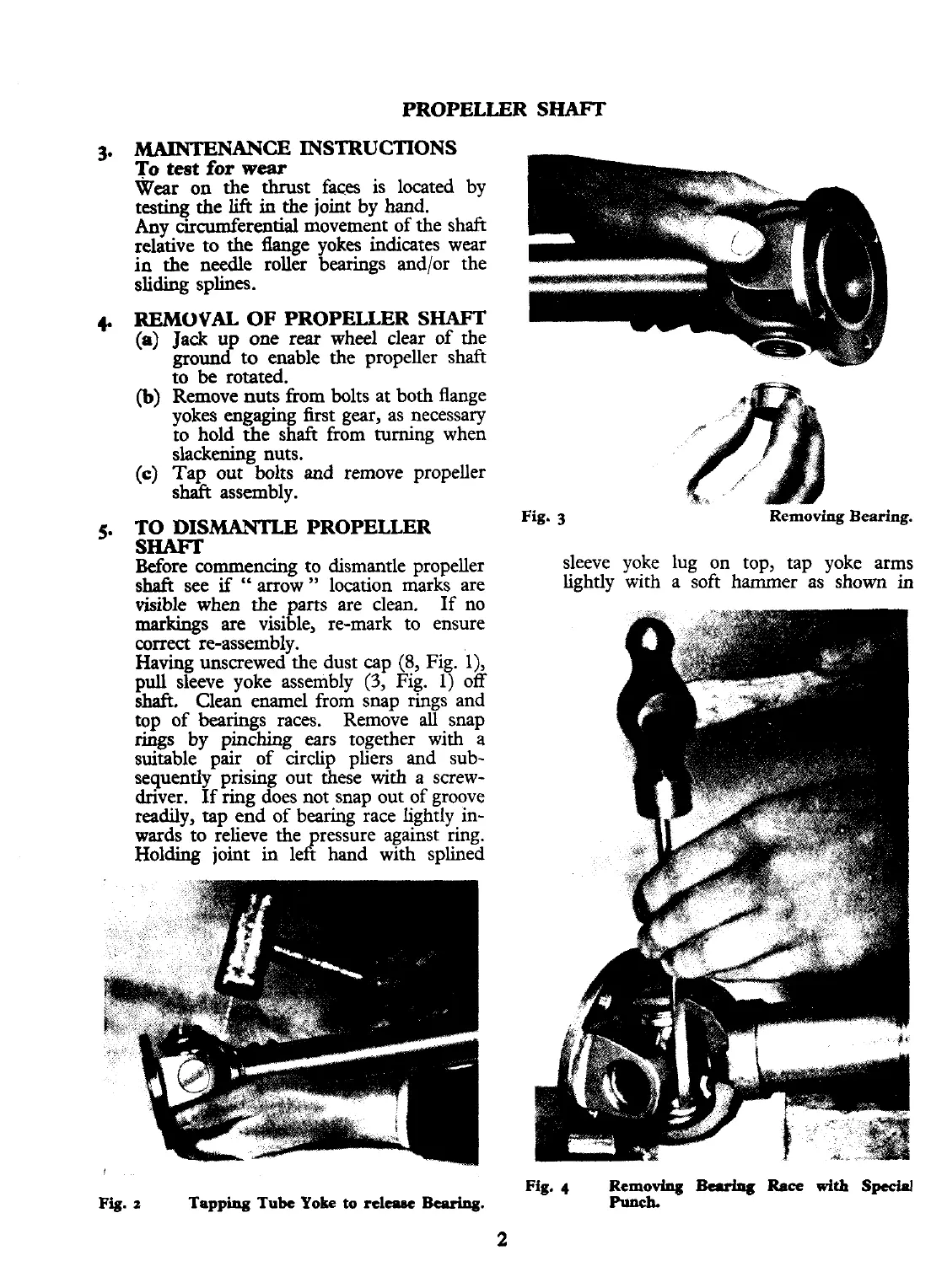

Fig.

4

Removing

Bcdq

Race

with

Specinl

Punch.

Loading...

Loading...